A chemical teaching instrument dust removal and drying device and its use method

A technology for drying devices and instruments, applied in chemical instruments and methods, drying gas arrangement, cleaning methods using tools, etc., can solve the problems of increased labor intensity, poor convenience of dust removal of instruments, low drying efficiency of instruments, etc., and achieves practicability. Good, fast drying, avoid local overheating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing:

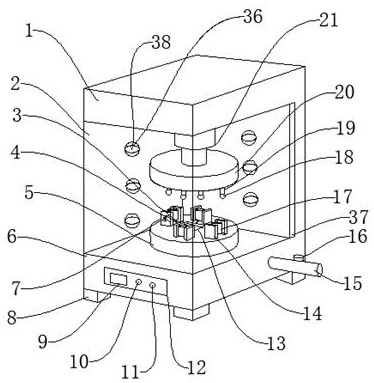

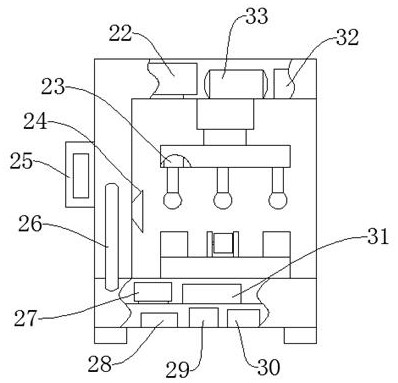

[0026] Such as Figure 1-Figure 5As shown, a chemical teaching instrument dust removal and drying device includes a base 6, a support 1, a connecting plate 20 and a support plate 5, the four corners of the lower end of the base 6 are provided with support pads 8, and the support pads 8 are bonded to the On the base 6, the support pad 8 can provide reliable support for the base 6 to ensure the stability of the base 6, and the middle part of the side wall of the base 6 is provided with an operation panel 12, and the inside of the operation panel 12 Embedded on the base 6, the operation panel 12 is provided with a display screen 9, a control knob 10, and a switch 11, and the other side wall of the base 6 is provided with a drain pipe 15, and the drain pipe 15 can store The water in the water tank 13 is discharged, and the middle part of the upper end of the drain pipe 15 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com