Die punching machine

A punch and die technology, used in forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of low stamping accuracy, large volume, and high cost, achieve low manufacturing costs and maintenance costs, reduce labor intensity, and improve The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

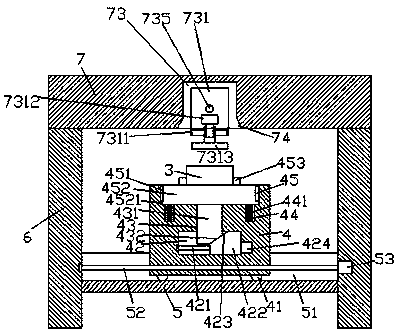

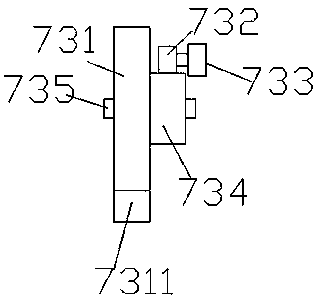

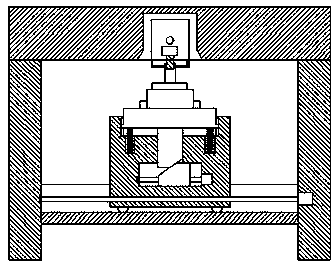

[0022] Such as Figure 1-Figure 6 As shown, a mold stamping device of the present invention includes a top beam 7 and pillars 6 fixed on the bottom of both sides of the top beam 7, and brackets 5 are fixed between the pillars 6 below the top beam 7, The bracket 5 is provided with a first sliding groove 51, and the first sliding groove 51 is provided with a first screw rod 52 extended from left to right, and the first screw rod 52 is screw-fitted and connected with Sliding block 4, the upper part of the sliding block 4 is located outside the top of the bracket 5, the inside of the sliding block 4 is provided with a sliding cavity 42, the top of the sliding block 4 is provided with a square groove 45, the square Between the middle position of the inner bottom surface of the groove 45 and the middle position of the inner top of the sliding joint cavity 42, there is a communication groove 43 connecting the interior of the sliding joint block 4 up and down. A screw-shaped rod 421,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com