High-precision universal cylindrical grinder and cooling system

A cooling system, cylindrical grinding machine technology, applied in grinding machines, grinding/polishing equipment, grinding/polishing safety devices, etc., can solve the problems of difficult quality control, surface burns, easy chipping, etc. Cost saving and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

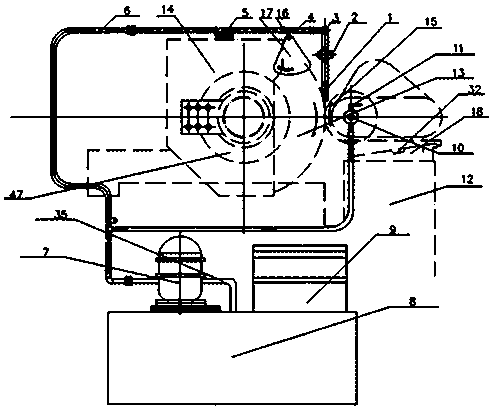

[0030] Such as Figures 1 to 2 As shown, the external grinding mechanism (56) is composed of an external main shaft (48), a bracket (5), a grinding wheel cover (14), an external grinding wheel (13), a triangular baffle (17), and a flange (47) , said cylindrical grinding wheel (13) is fixed on the flange (47), and the flange (47) is installed on the external main shaft (48).

[0031] Said grinding wheel cover (14) is provided with support (5), on the one hand cooling pipe is fixed on the grinding wheel cover (14), on the other hand can make hard tube (4) move back and forth, move up and down.

[0032] The said hexagonal nut (16) is used to fix and adjust the triangular baffle (17), and the said triangular baffle (17) is used to block the grinding fluid brought by the centrifugal force generated by the rotation of the outer round grinding wheel (13). , the gap between the triangular baffle (17) and the outer grinding wheel (13) can be adjusted to adapt to the consumption of the...

specific Embodiment approach 2

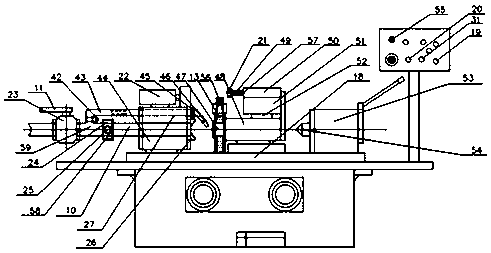

[0039] Such as figure 2 As shown, the internal grinding mechanism (57) includes an internal grinding tool rod (49), an internal grinding wheel (21), an internal main shaft (50), an internal grinding wheel support body shell (51) and an internal grinding wheel support body shell rotating Shaft (52).

[0040] The said internal grinding wheel (21) is fixed on the inner grinding rod (49), the said inner grinding rod (49) is installed on the inner main shaft (50), and the inner grinding rod (49) is provided with different Long and short specifications, capable of machining inner diameters of different sizes.

[0041] The said inner circle main shaft (50) is arranged in the inner circle grinding wheel support body shell (51), and the inner circle grinding wheel support body shell (51) can be turned up and down, when needing inner circle grinding, turn it down for inner circle grinding Grinding.

[0042] The alleged inner grinding wheel support housing (51) is set on the upper pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com