Man-machine safety protection system and safety protection method

A safety protection and human-machine technology, applied in the direction of manipulators, computer parts, instruments, etc., can solve the problems of high cost and limited visual sensors, and achieve the effect of low cost, flexible configuration and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

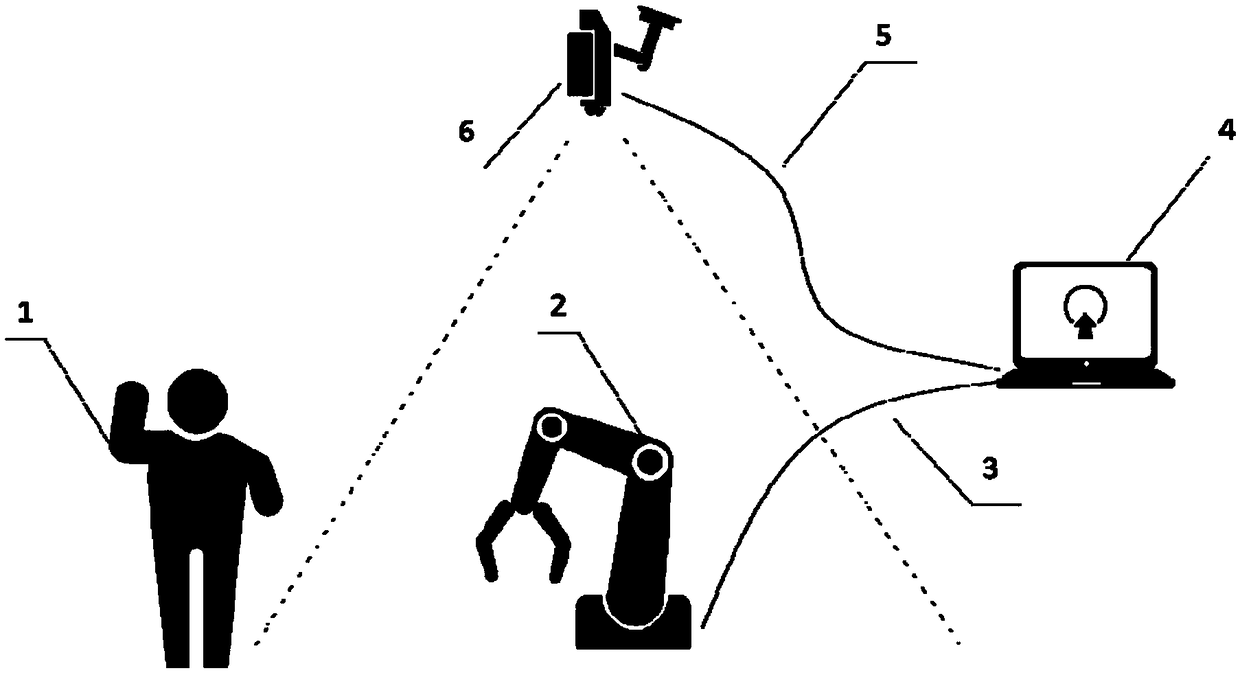

[0044] The present invention will be described in detail in conjunction with accompanying drawing now. This figure is a simplified schematic diagram only illustrating the basic structure of the present invention in a schematic manner, so it only shows the components relevant to the present invention.

[0045]In this embodiment, there is one robot 2 in the working area as an example for illustration. When there are multiple robots 2, the shooting range of the camera 6 may be larger.

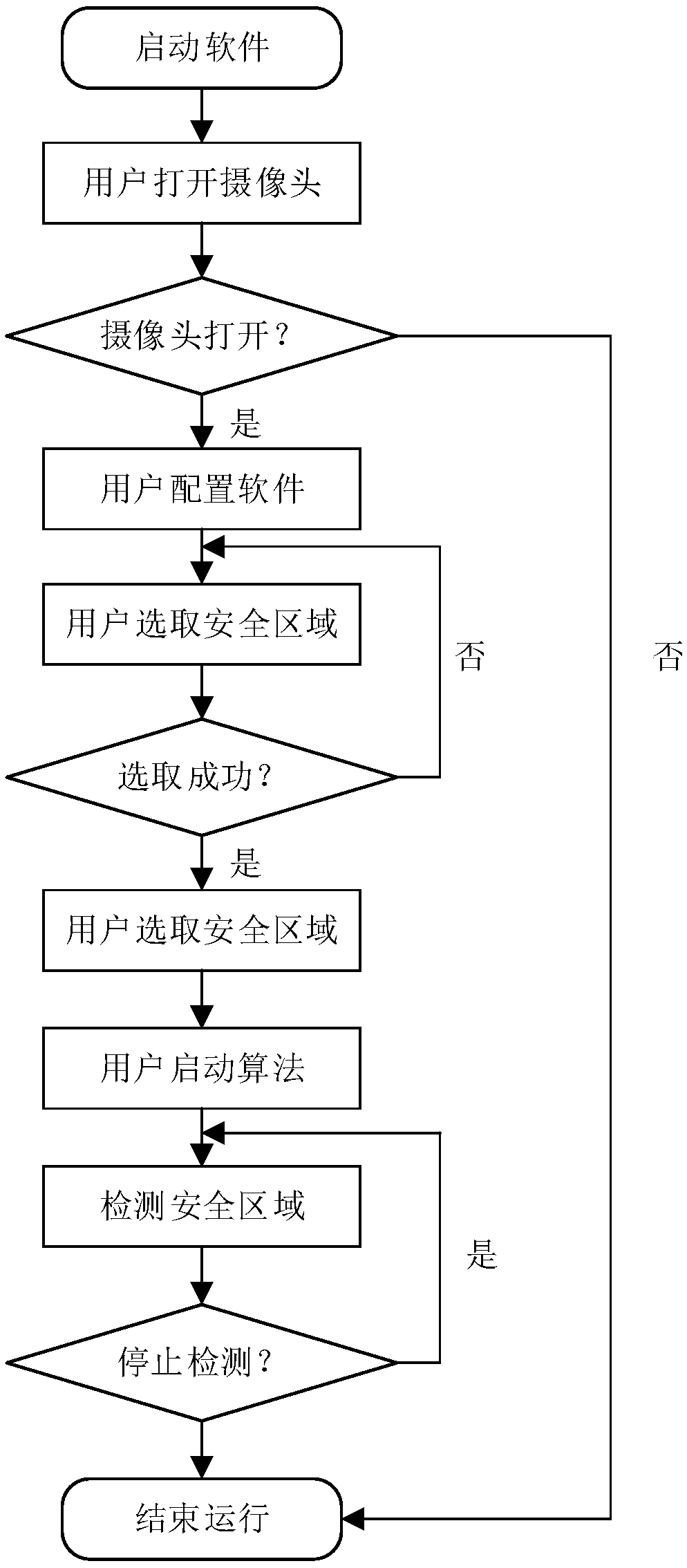

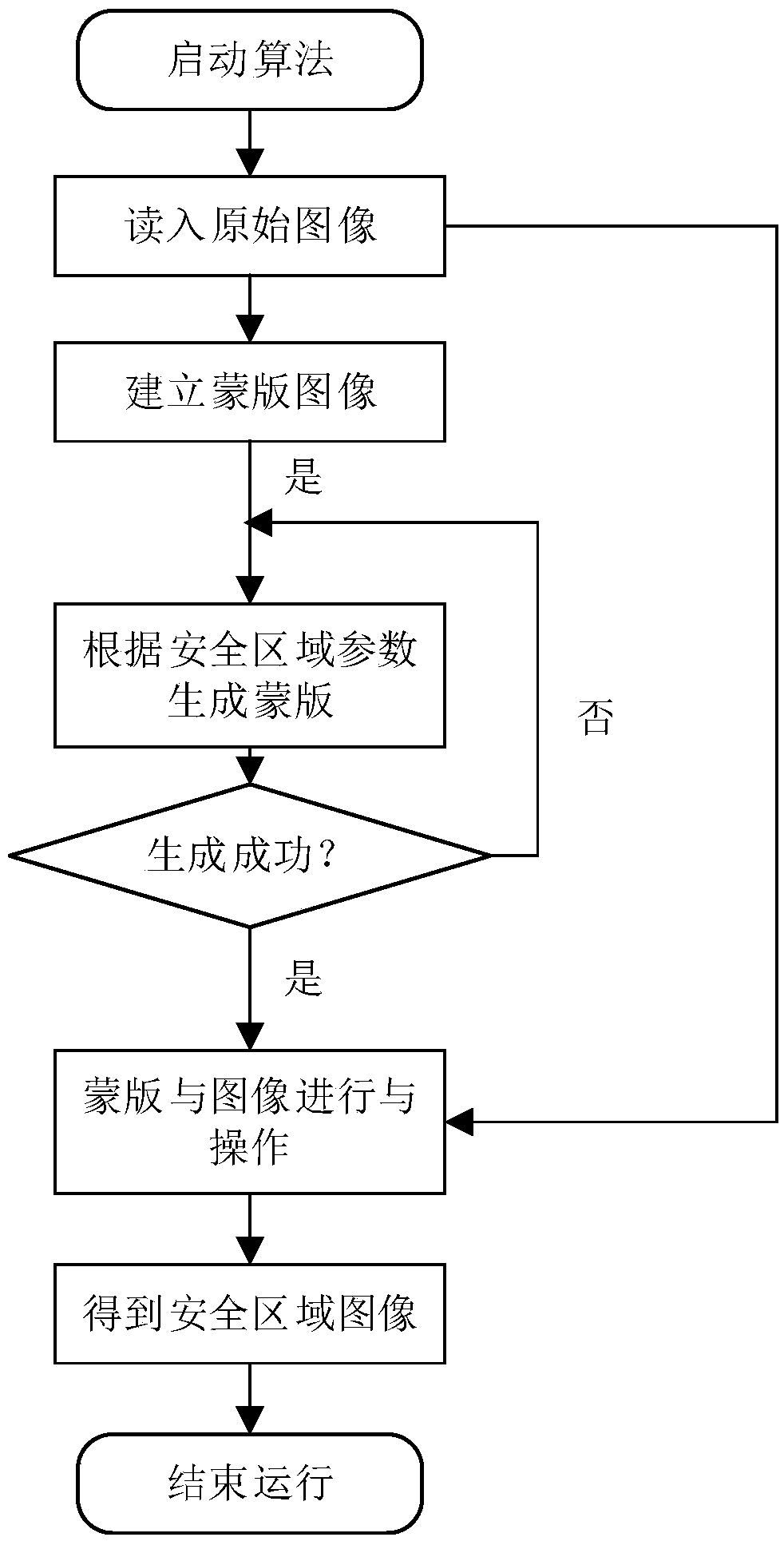

[0046] Such as figure 1 As shown, a human-machine safety protection system of the present invention includes a robot 2, a camera 6 and a computer 4. In order to facilitate subsequent data processing, the camera 6 is installed directly above the robot 2, and the robot 2 and the camera 6 are both Connected with the computer 4, the robot 2 has at least one movable execution part; the camera 6 is used to take images within the detection range of the surrounding environment of the robot 2, and send th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com