Built-in capsule suspension gas spring

A gas spring and capsule technology, used in suspension, vehicle spring, elastic suspension, etc., can solve the problems of unfavorable arrangement of the outer diameter of the airbag, the spring stiffness cannot be changed actively, and the oil flow resistance is large, so as to achieve safe driving and safety. Reliable handling, reduced vehicle nodding and roll angle, good ride comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

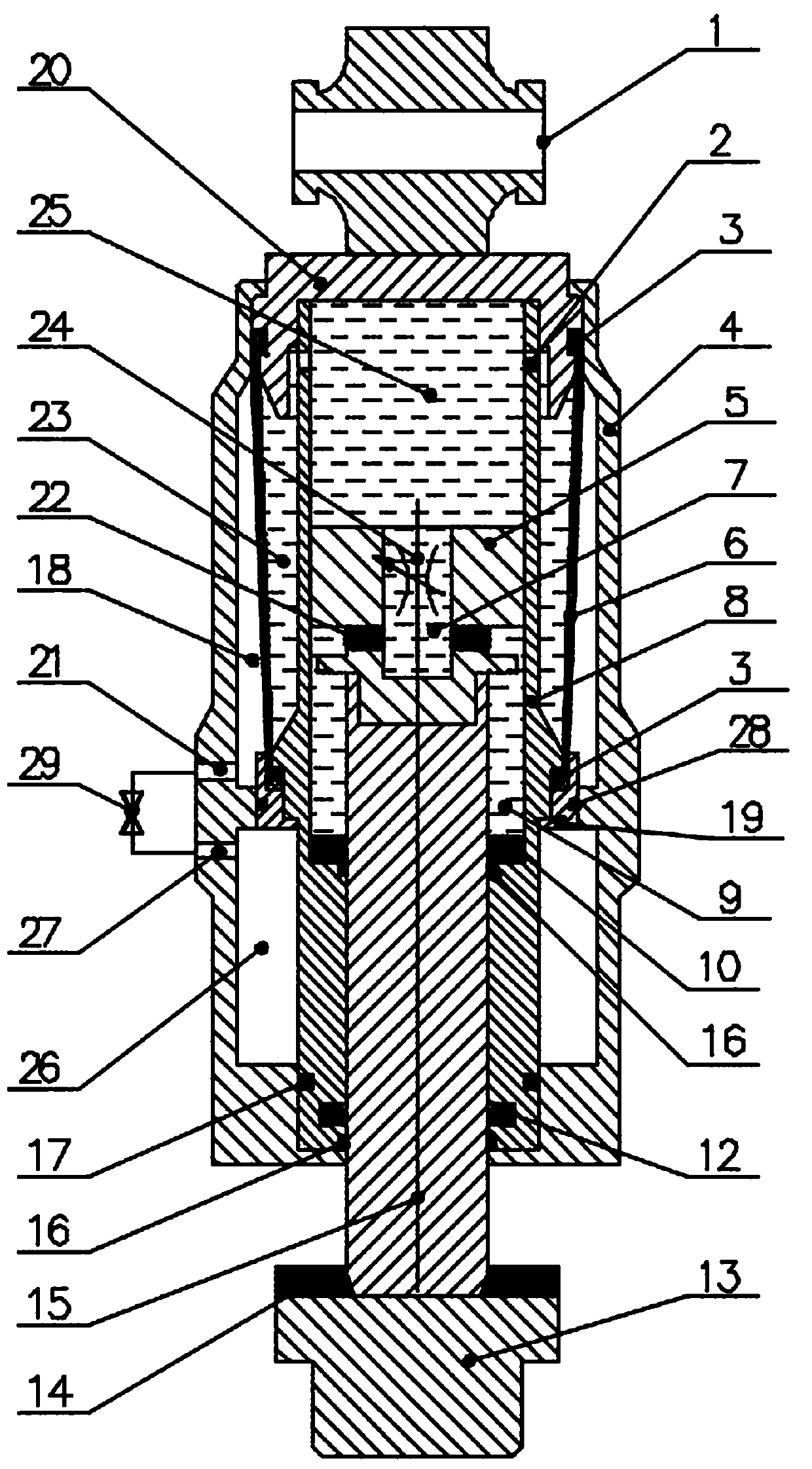

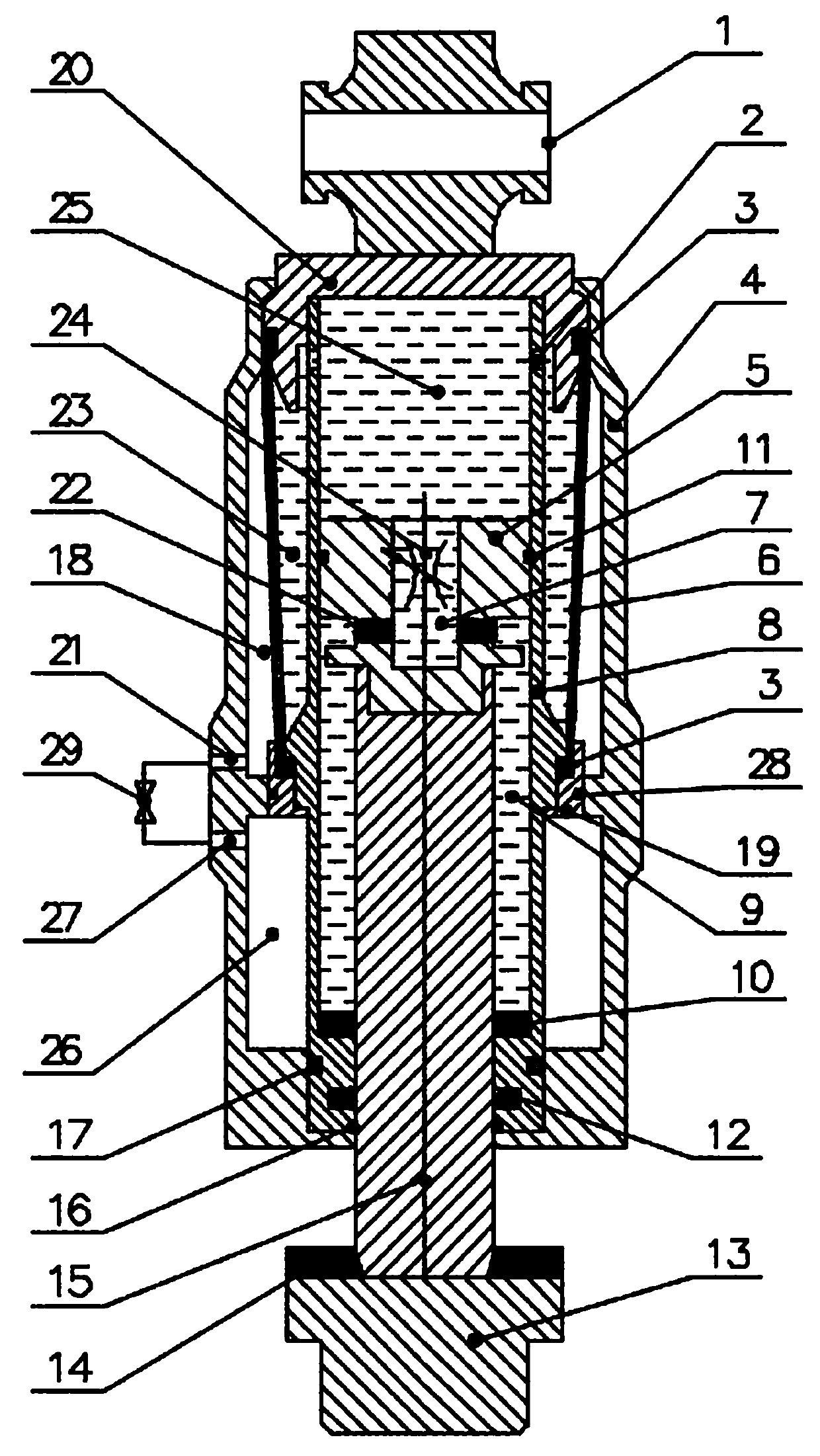

[0035] A gas spring with a built-in capsule suspension, comprising a cylinder head 20, an outer cylinder tube 4, an inner cylinder tube 8, a piston rod 15 and a capsule 6. The inner cylinder tube 8 is fixed in the outer cylinder tube 4 through the cylinder head 20. The inner cylinder 8 is movably provided with a piston 5 for dividing the inner cylinder 8 into a first oil chamber 25 and a second oil chamber 9. After the separation, the first oil chamber 25 is located above the second oil chamber 9. The piston rod 15 extends into the inner cylinder 8 and the piston 5 is fixedly connected; between the outer cylinder 4 and the inner cylinder 8 are provided a main air chamber 18 and an auxiliary air chamber 26, the main air chamber 18 and the auxiliary air chamber 26 The isolation seal ring 28 fixedly arranged between the outer cylinder tube 4 and the inner cylinder tube 8 is partitioned, and the main air chamber 18 is located above the auxiliary air chamber 26 after separation; furt...

Embodiment 2

[0055] This embodiment is basically the same as Embodiment 1, and the main difference is that an upper support ring 11 is provided between the piston 5 and the inner cylinder 8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com