High-precision conveying production line

A production line, high-precision technology, applied in the direction of conveyor, transportation and packaging, can solve problems such as increasing the cost of production, and achieve the effect of precise transportation and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

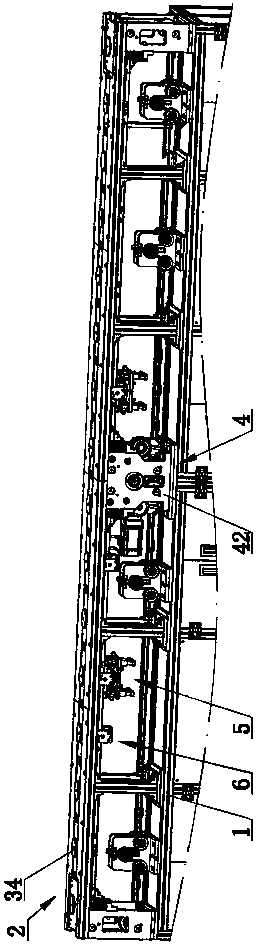

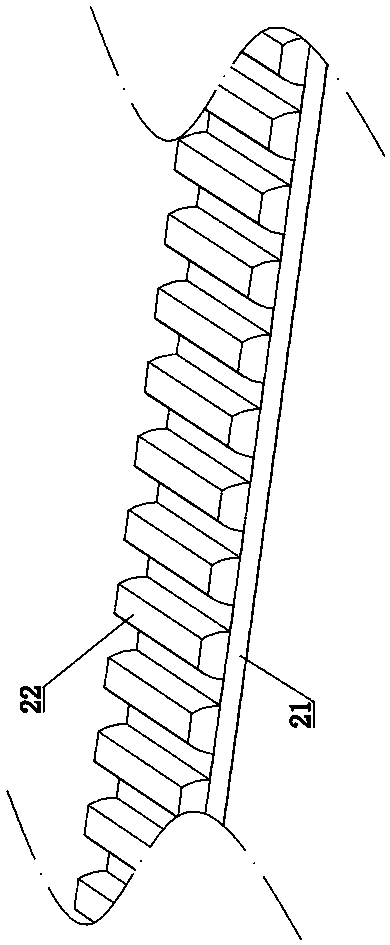

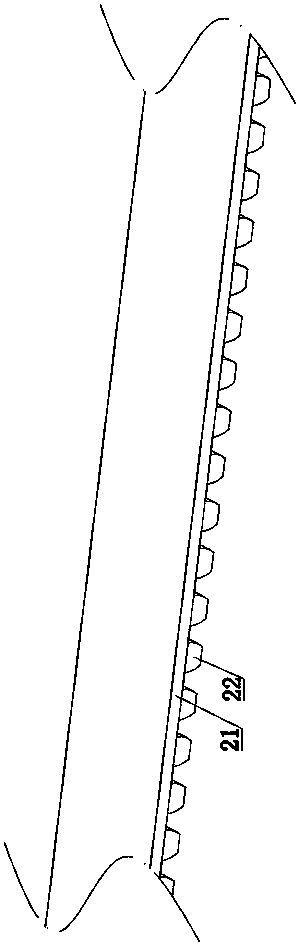

[0036] Such as Figure 1 to Figure 11 Shown is the first embodiment of a high-precision conveying production line of the present invention, including a frame 1, at least two production lines 2 disposed on the frame 1, a synchronous belt 21 disposed on the production line 2, and a conveyor that moves on the synchronous belt 21 Disc 3, the upper surface of the synchronous belt 21 is provided with a first rack 22, the lower surface of the synchronous belt 21 is a plane, and the conveying disc 3 is provided with a second rack 31 corresponding to the first rack 22; Said that one of the production lines 2 and the other production line 2 is provided with a carrying connection mechanism 4, the carrying connection mechanism 4 includes a base 41, at least one vertical plate 42 installed on the base 41, and a synchronization mechanism installed on the vertical plate 42. The transmission device 43 and the synchronous driving device 44 that drives the synchronous transmission device 43 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com