Control console used for material receiving machine

A technology of consoles and splicers, applied in the direction of conveyor control devices, conveyor objects, transportation and packaging, etc., can solve the problems of production line shutdown efficiency, hidden dangers of personal safety of staff, losses, etc., and achieve the effect of delaying oxidation and corrosion Speed, simplification of the operation process, and the effect of protecting the mechanical device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

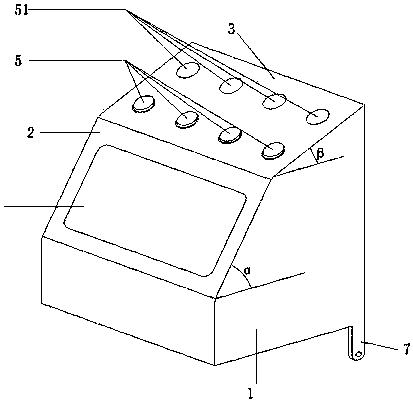

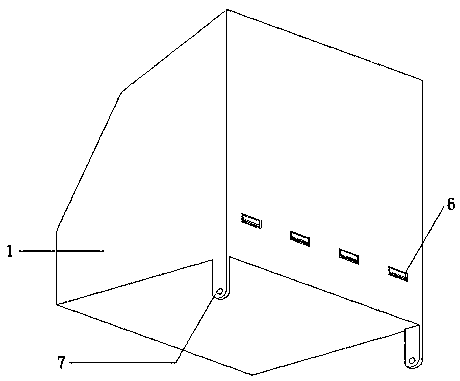

[0024] The invention will now be further described in detail in conjunction with the accompanying drawings and embodiments. These accompanying drawings are all simplified schematic diagrams, and only illustrate the basic structure of the present invention in a schematic manner, so it only shows the configuration related to the present invention.

[0025] Such as Figure 1 to Figure 2 As shown, the display plane 2 forms an angle α with the horizontal plane, and the value of the α angle is 40~60°. The button plane 3 is set above the display plane 2. The button plane 3 forms an angle β with the horizontal plane, and the value of the β angle is 15~30°. °. The bottom of the body 1 is provided with a rotating mechanism 7 that can rotate around the fixed shaft of the splicer. The display plane 2 is provided with a display frame 4 . The button plane 3 is provided with a button 5 and a buttonhole 51 reserved for installing the button 5 . The back of the main body 1 is provided with a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap