Automatic blank arrangement machine suitable for assembly line

A billet unloading machine and assembly line technology, which is applied in the direction of conveyors, unstacking of objects, conveyor objects, etc., can solve the problems of high manual duty, records, and inability to apply production lines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

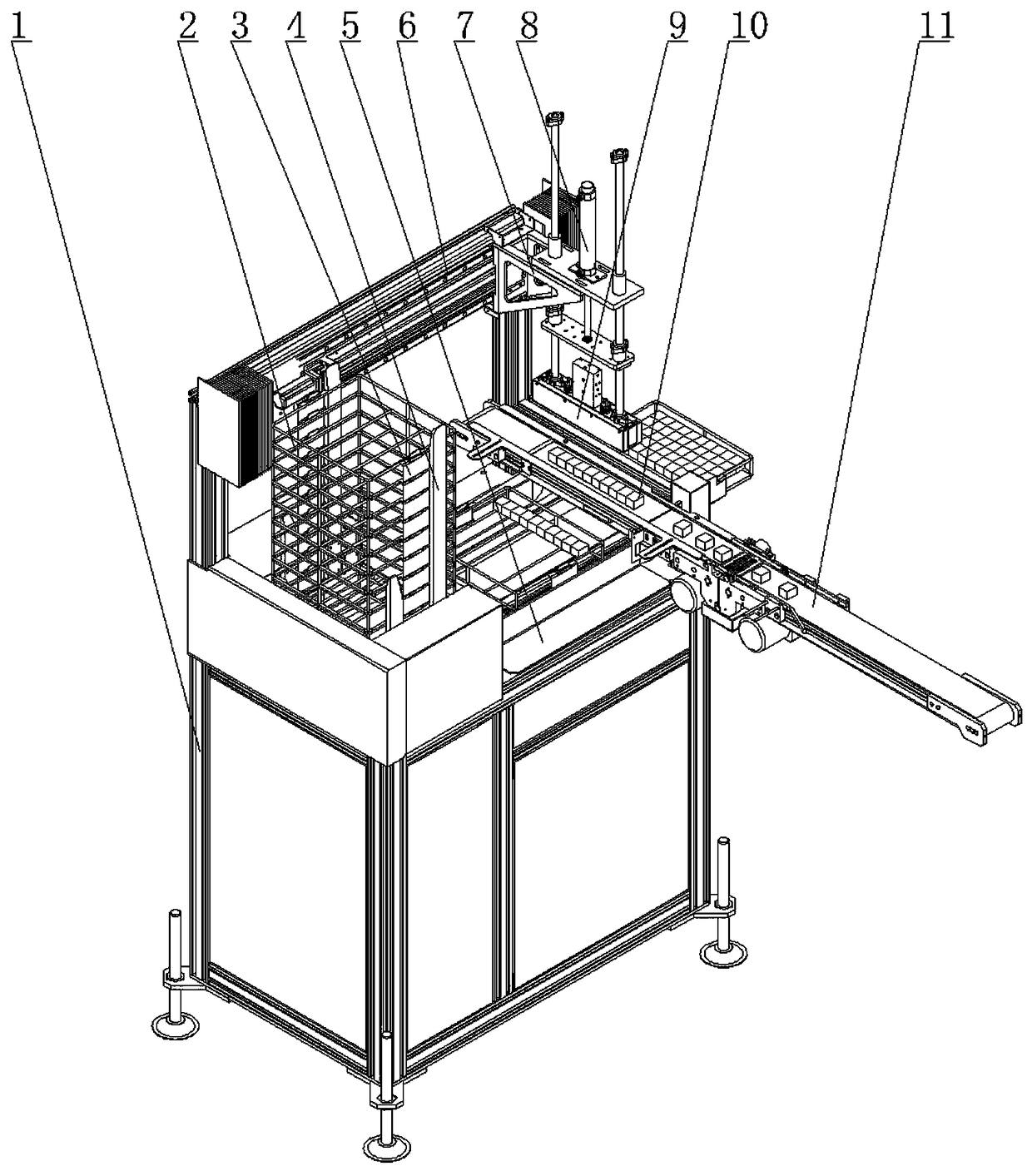

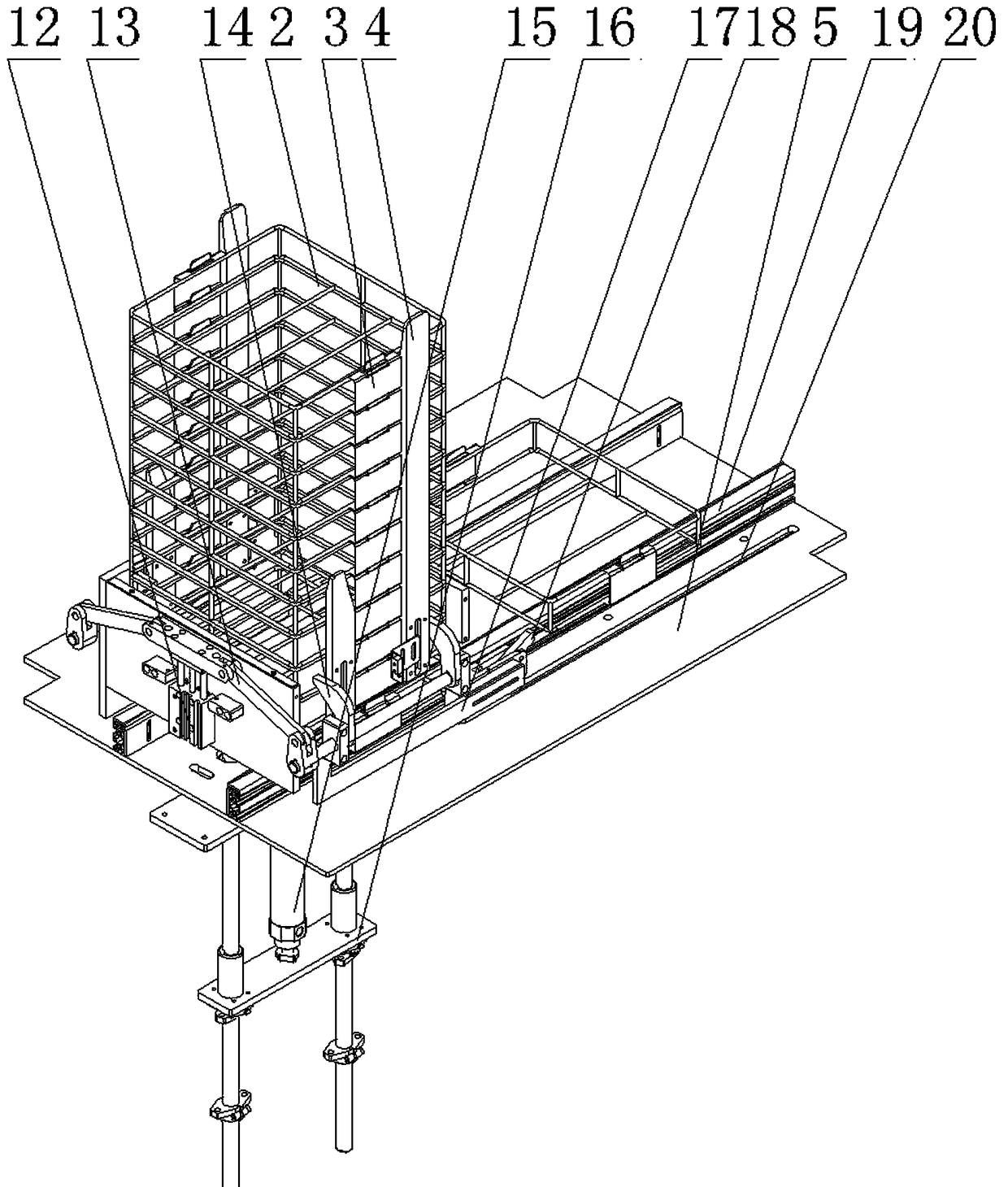

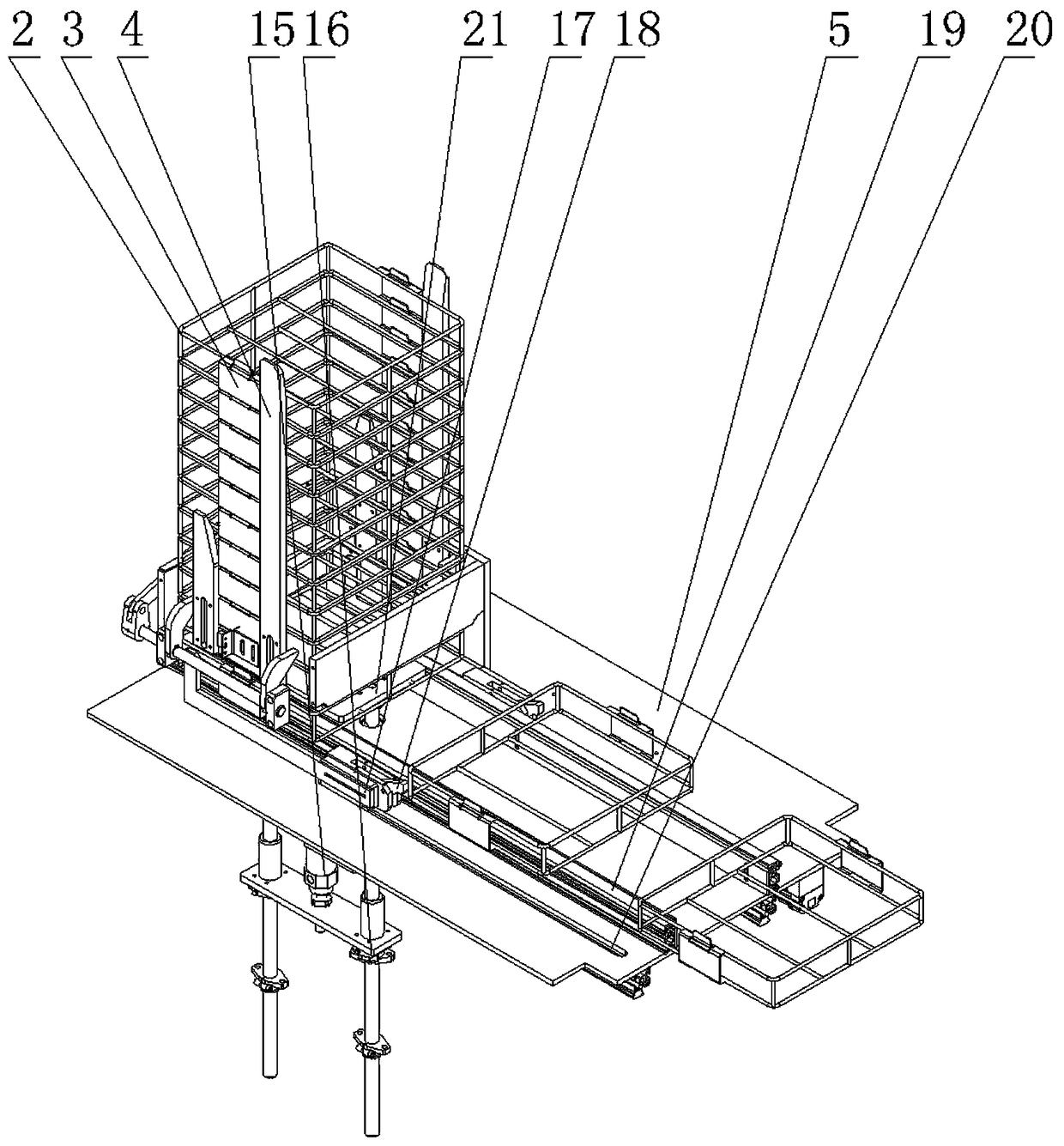

[0011] The present invention will be further described below in conjunction with accompanying drawing by embodiment:

[0012] Such as figure 1 , figure 2 , image 3 with Figure 4 As shown, a kind of automatic blanking machine suitable for assembly line of the present invention, it comprises frame 1, is provided with worktable 5 on the frame, has two slide rails 19 on the worktable 5, on one side of frame 1 There is a conveying device 11 for conveying blanks 10, and there is a horizontal moving device 6 on one side of the frame 1 adjacent to the above-mentioned conveying device 11, and the above-mentioned horizontal moving device 6 drives the horizontal moving frame 7, and there is an up and down lifting device on the horizontal moving frame 7 8. The above-mentioned up and down lifting device 8 drives the blank sucker 9, which is characterized in that there is a basket stacking frame 4 on the opposite side of the above-mentioned conveying device 11, and the above-mentioned...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com