Recycling cooling backwater surplus energy utilization process and facility

A technology of circulating cooling and surplus energy, which is applied in water shower coolers, mechanical equipment, hydroelectric power generation, etc., which can solve the lack of supplementary air and cooling fluid circulation functions, the inability to ensure the effective use of water resources and surplus power, and heat exchange components Issues such as less publicity, to achieve the effect of reducing manual duty, saving energy consumption, and saving electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

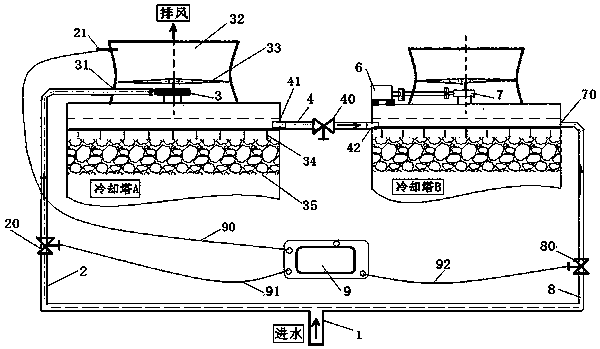

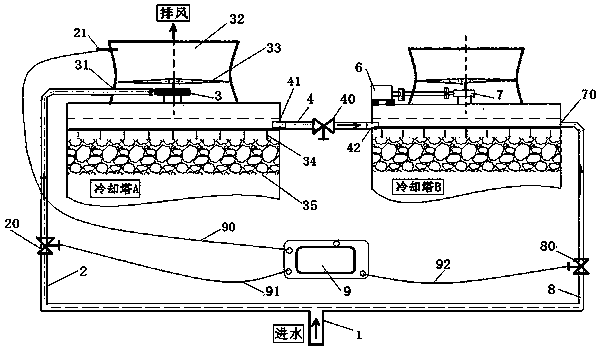

[0028] like figure 1 The cooling tower residual pressure utilization facility has a water inlet main pipe, a branch A, a branch B, a cooling tower A, and a cooling tower B, and the water inlet main pipe is respectively connected to the branch A and the branch B, and the branch A is connected to the cooling tower The water inlet A of A, the branch A is provided with a control valve A, the branch B is connected to the water inlet B of the cooling tower B, the branch B is provided with a control valve B, and the fan impeller at the top of the cooling tower A has a common rotating shaft. Water turbine impeller, cooling tower A is provided with a rotating speed measuring device for measuring the water turbine impeller.

[0029] There is a reducer with a common shaft under the fan impeller on the top of cooling tower B, and the reducer is connected and driven by a motor; in addition, there is a controller; there is a control line between the controller and the control valve A, which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com