Roller turnover device for laminated glass film paving machine

A technology of laminated glass and flipping device, which is applied to lamination device, lamination, layered products, etc., can solve the problems of single film laying, high production intensity, and simple structure, so as to reduce labor intensity, reduce production cost, increase The effect of economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to make the objectives, technical solutions and advantages of the present invention clearer, the following further describes the present invention in detail with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

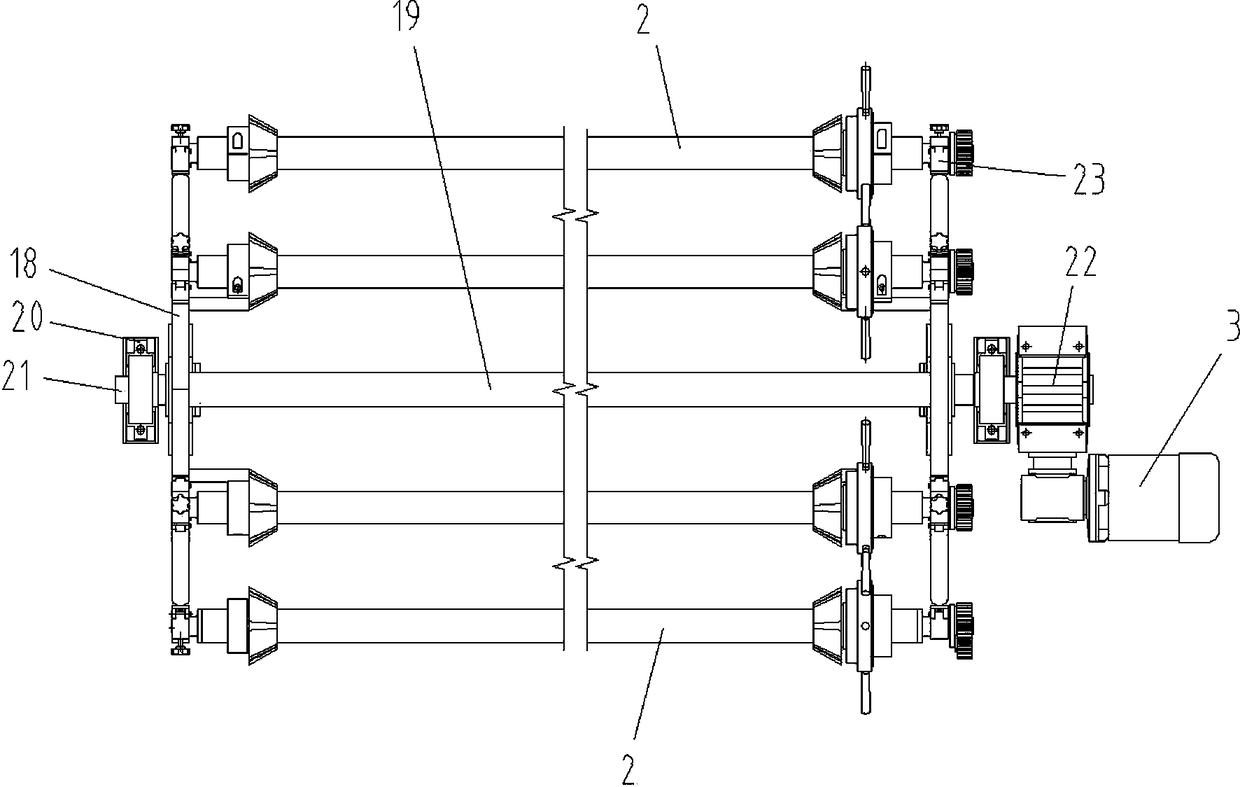

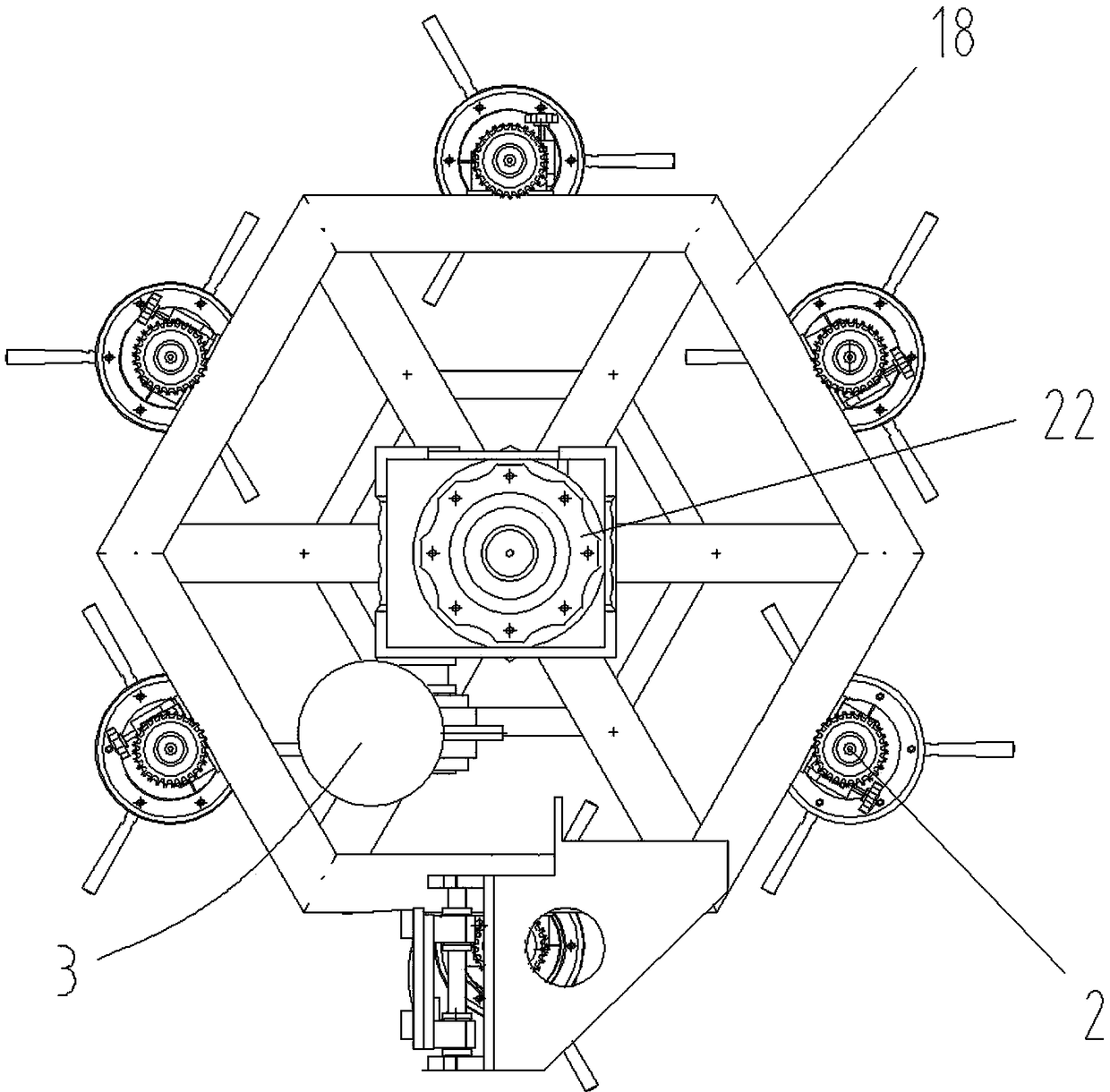

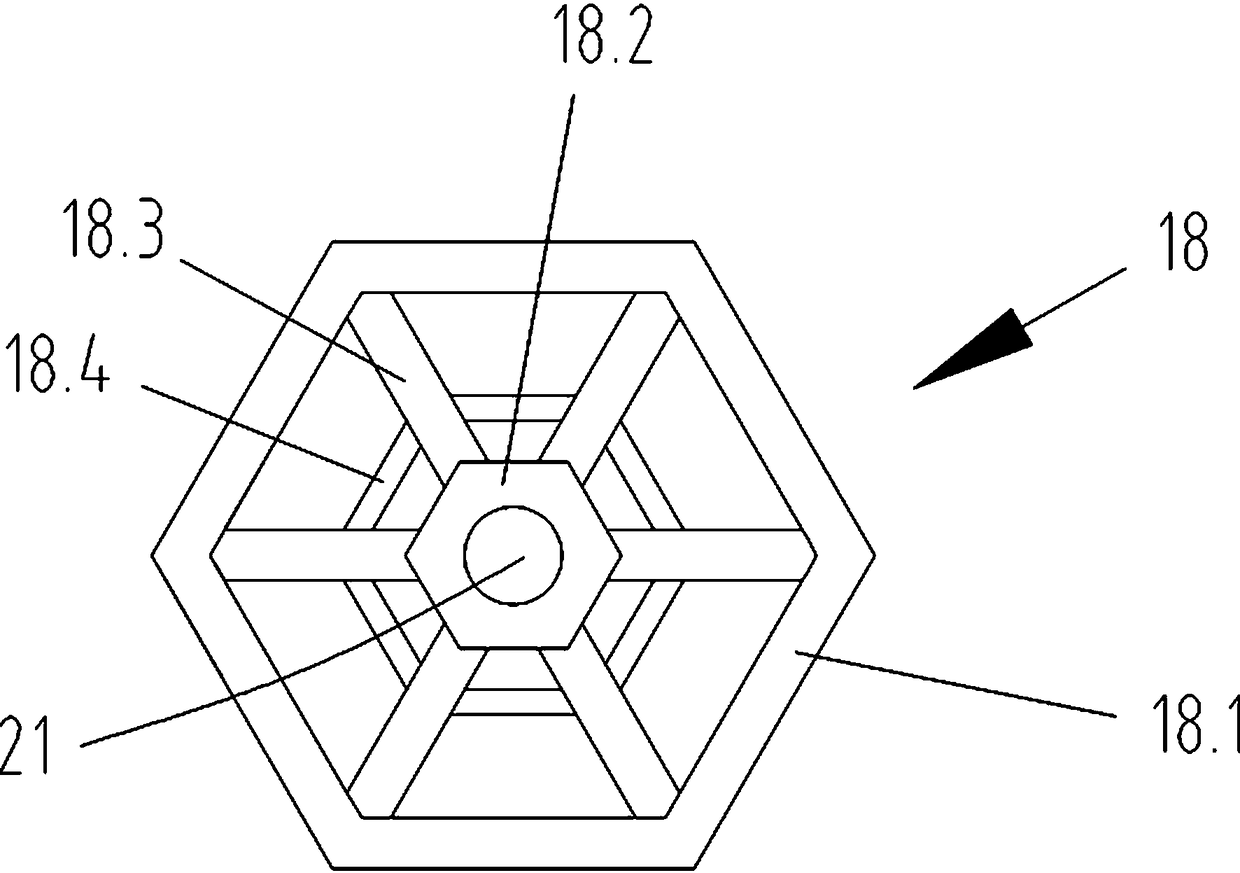

[0014] Such as Figure 1-Figure 3 As shown, the present invention provides a roller turning device for a laminated glass laminating machine, which includes a bottom plate. Two first bearing seats 20 are symmetrically welded and fixed above the bottom plate. The bearing holes of the two first bearing seats 20 are coaxial Is arranged, in each first bearing seat 20, the connecting shaft 21 is rotatably connected through a first bearing, and one end of each connecting shaft 21 is matched with a roller frame 18, and the roller frame 18 includes a regular hexagonal frame 18.1. A hexagonal plate 18...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap