Automatic paper supply device

A paper feeding device and automatic technology, applied in transportation and packaging, winding strips, sending objects, etc., can solve the problems of paper waste, student injury, toilet paper scratches and bleeding, etc., and achieve the effect of easy use and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

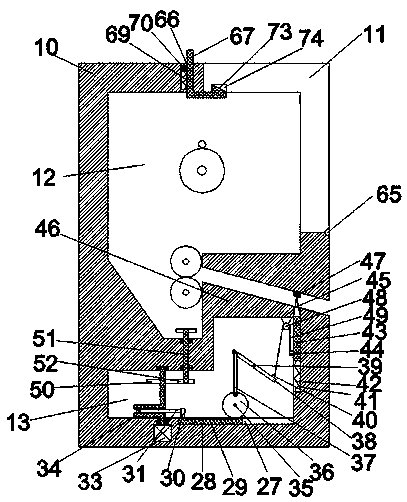

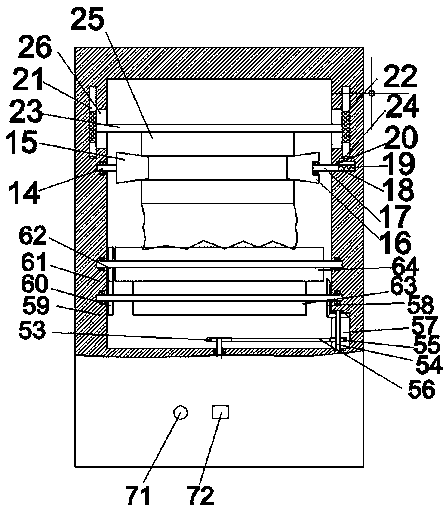

[0017] Such as Figure 1-2 As shown, the device of the present invention is an automatic paper feeding device, comprising a body 10, a first cavity 12 disposed inside the body 10 with its opening facing right, and a paper compartment cover 11 rotatably connected to the body 10. The front end wall of the first cavity 12 is rotatably provided with a first rotating shaft 14, and the rear end surface of the first rotating shaft 14 is fixedly provided with a first locking block 15. In addition, a telescopic slot 18 is arranged parallel to the first rotation axis, and a first pressing spring 19 is fixedly arranged on the rear end wall of the telescopic slot 18, and the other end of the first pressing spring 19 is fixedly connected with a sliding rod. 17. The upper end wall of the telescopic slot 18 is communicated with a first limiting groove, and the first limiting groove is provided with a first limiting block 20 fixedly connected to the rear end surface of the sliding rod 17. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com