Small-scale copper wire winding mechanism capable of moving leftwards and rightwards

A winding mechanism, left and right technology, applied in the direction of conveying filamentous materials, thin material processing, transportation and packaging, etc., can solve the problems of fixed movement troubles, fixed limit positions, and inability to meet small cylinder winding use, etc. To achieve the effect of guaranteed winding effect, convenient installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

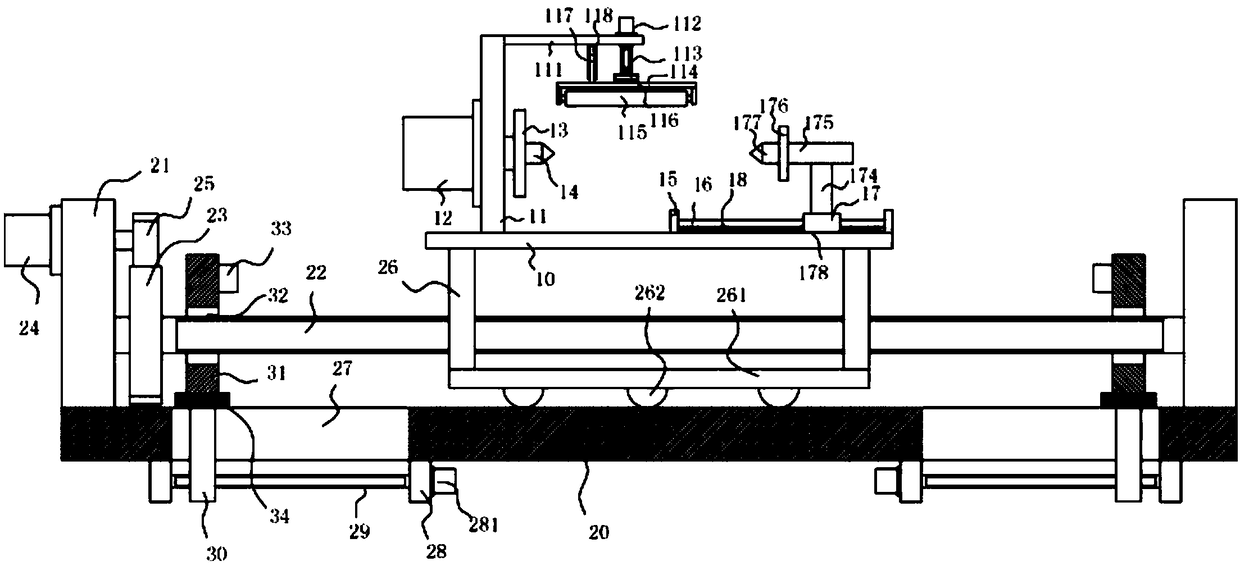

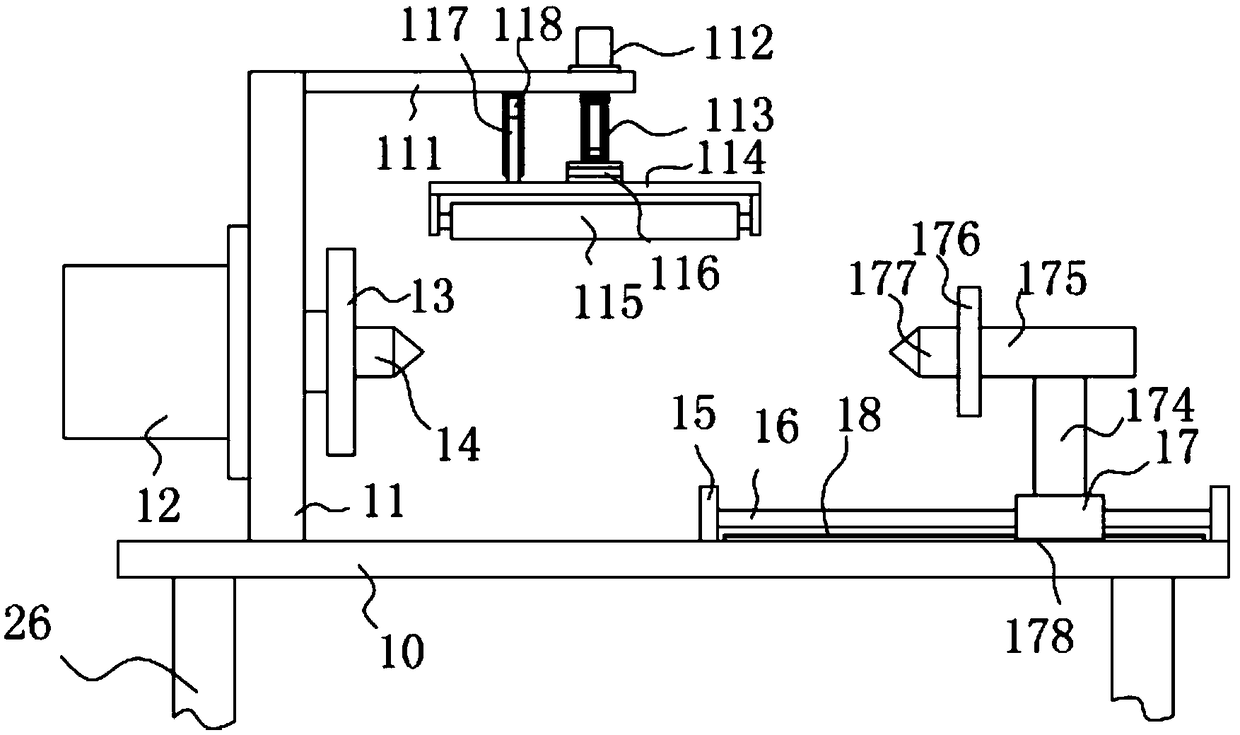

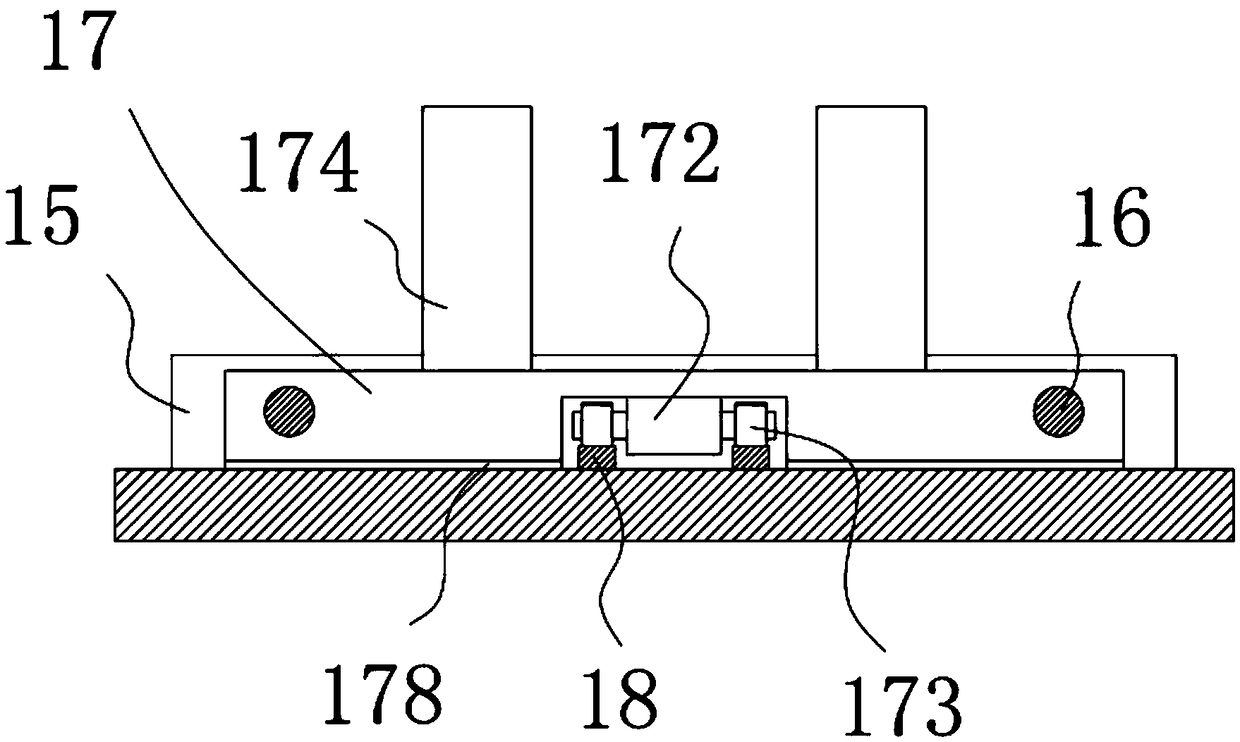

[0022] Example: see Figure 1 to Figure 3 As shown, a left and right movable small-sized copper wire winding mechanism includes a main base plate 10 and a support bracket 20, side support plates 21 are fixed on the top surfaces of the left and right sides of the base plate of the support bracket 20, and the main transverse screw rod 22 The two ends of the two side support plates are hinged on the two side support plates 21 through bearings. One end of the main transverse screw rod 22 is fixed with a mobile transmission gear 23, and the outer wall of the side support plate 21 is fixed with a main mobile motor 24. The output shaft of the main mobile motor 24 Pass through the side support plate 21 and be fixed with a mobile drive gear 25, the mobile drive gear 25 is meshed with the mobile transmission gear 23, the bottom surface of the main base plate 10 is fixed with two lower vertical plates 26, and the two lower vertical plates 26 are screwed together. In the main transverse s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com