Cover pressing device with quickly replaceable pressing head

An indenter and capping technology, applied in flange-type bottle caps and other directions, can solve problems such as inconvenience, damage or looseness of the bottle cap indenter, etc., and achieve the effects of improving production efficiency, quick and convenient assembly, and good practical use value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

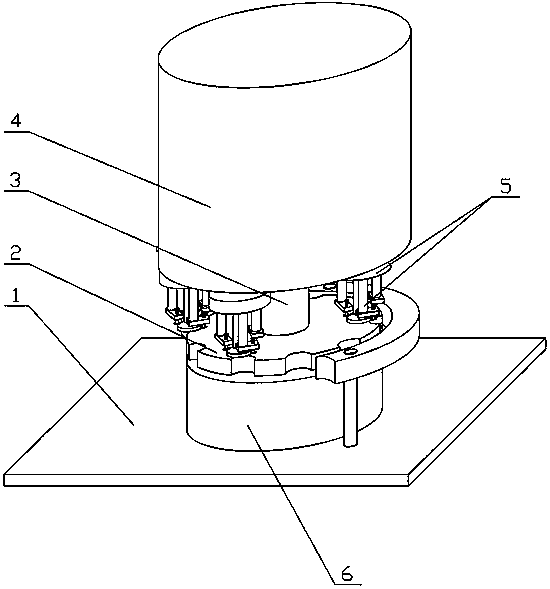

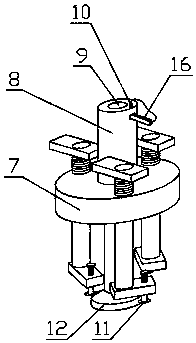

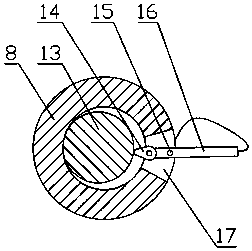

[0011] see Figure 1-Figure 3 , the present invention is a capping device that can quickly replace the indenter. It has a base 1, a driving member 6 is arranged on the base, a rotating disk 2 is arranged on the driving member, and a rotating head 4 is connected to the rotating disk through a rotating column 3. The bottom of the rotating head is provided with several bottle cap pressing heads 5 along the circumferential direction, and each bottle cap pressing head is connected to the connecting rod 13 arranged at the bottom of the rotating head. 12. The rotary blade 11 surrounding the bottle cap pressing table and the transmission column 8 connected with the rotary head, the center of the transmission column is provided with an inner hole 9, which is used for socketing with the connecting rod, and the inner hole 9 of the transmission column An adjustment hole 17 is provided on the side wall of the hole, and an adjustment rod 16 is hingedly mounted in the adjustment hole. A cam ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com