Preparation method of multiscale material reinforced resin-based antifriction and antiwear composite

A technology for strengthening resin-based and composite materials, which is applied in the preparation of resin-based anti-friction and wear-resistant composite materials and the preparation of modified benzoxazine resin-based anti-friction and wear-resistant composite materials, which can solve the problem of reducing the temperature resistance level of matrix resin , increase the amount of wear, it is difficult to realize the friction reduction, wear resistance and mechanical strength of benzoxazine resin, and achieve the effect of improving mechanical properties, optimizing the aggregate structure, and improving the friction reduction and wear resistance performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] In this embodiment, a method for preparing a multi-scale material-reinforced resin-based anti-friction and wear-resistant composite material includes the following steps:

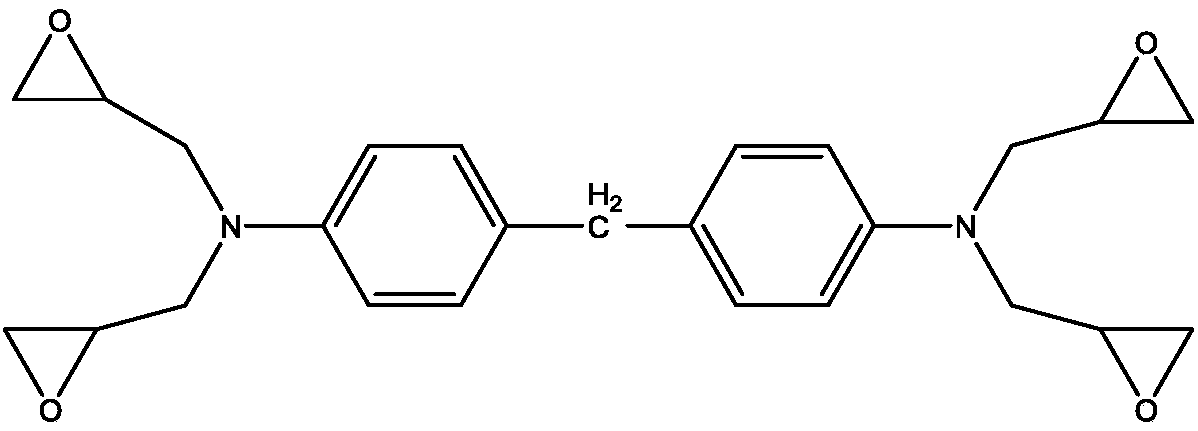

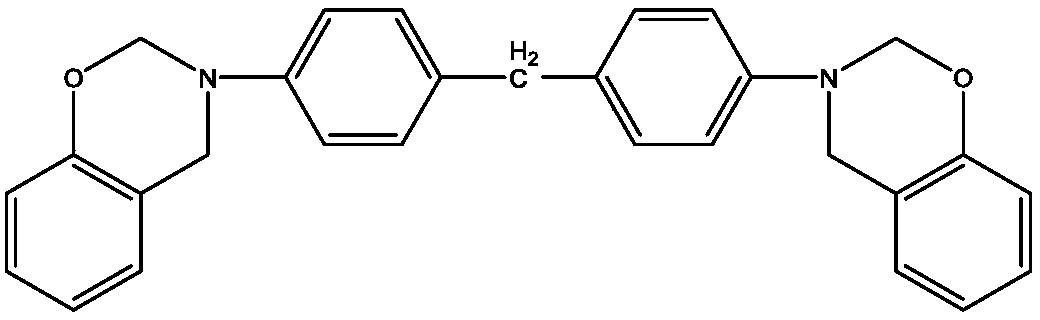

[0019] a. Mix 50g of phenoxy resin with 200g of AG-80 epoxy resin to form a reactant system, react at 165°C for 1.5 hours, after cooling, add methyl ethyl ketone, and obtain glue A with a product mass percentage concentration of 40%. ; The phenoxy resin adopts a linear polymer produced by the condensation reaction of bisphenol A and epichlorohydrin, and the average molecular weight Mn of the phenoxy resin is 90000; the molecule of the AG-80 epoxy resin is as follows;

[0020]

[0021] b. Using graphene, the number of layers of graphene is 2-10 layers, the particle size of graphene is 50-100nm, using butanone as a dispersant, dispersing 1.3890g graphene in 68.00g butanone dispersant, and ultrasonically Disperse, the preparation obtains the graphene dispersion liquid that mass percent concentration ...

Embodiment 2

[0030] This embodiment is basically the same as Embodiment 1, especially in that:

[0031] In this embodiment, a method for preparing a multi-scale material-reinforced resin-based anti-friction and wear-resistant composite material includes the following steps:

[0032] a. Mix 138g of phenoxy resin with 322g of AG-80 epoxy resin to form a reactant system, react at 160°C for 2 hours, after cooling, add toluene to obtain a glue solution A with a product mass percentage concentration of 40%; Described phenoxy resin adopts the linear polymer produced by the condensation reaction of bisphenol A and epichlorohydrin, and the average molecular weight Mn of phenoxy resin is 90000; The molecule of AG-80 epoxy resin is as follows;

[0033]

[0034]b. Using graphene, the number of layers of graphene is 2-10 layers, the particle size of graphene is 50-100nm, using butanone as a dispersant, dispersing 3.8330g graphene in 124.00g butanone dispersant, and ultrasonically Disperse, the prep...

Embodiment 3

[0043] This embodiment is basically the same as the previous embodiment, and the special features are:

[0044] In this embodiment, a method for preparing a multi-scale material-reinforced resin-based anti-friction and wear-resistant composite material includes the following steps:

[0045] a. Mix 11g of phenoxy resin with 99g of AG-80 epoxy resin to form a reactant system, react at 165°C for 1.5 hours, after cooling, add methyl ethyl ketone, and obtain glue A with a product mass percentage concentration of 40%. ; The phenoxy resin adopts a linear polymer produced by the condensation reaction of bisphenol A and epichlorohydrin, and the average molecular weight Mn of the phenoxy resin is 90000; the molecule of the AG-80 epoxy resin is as follows;

[0046]

[0047] b. Use graphene, the number of layers of graphene is 2-10 layers, the particle size of graphene is 50-100nm, use butanone as a dispersant, disperse 0.1530g graphene in 30.40g butanone dispersant, and ultrasonically...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com