Low-temperature impact-resistant nodular cast iron material and casting method thereof

A nodular cast iron, impact-resistant technology, applied in the field of nodular cast iron material casting, can solve problems such as complex production processes, and achieve the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

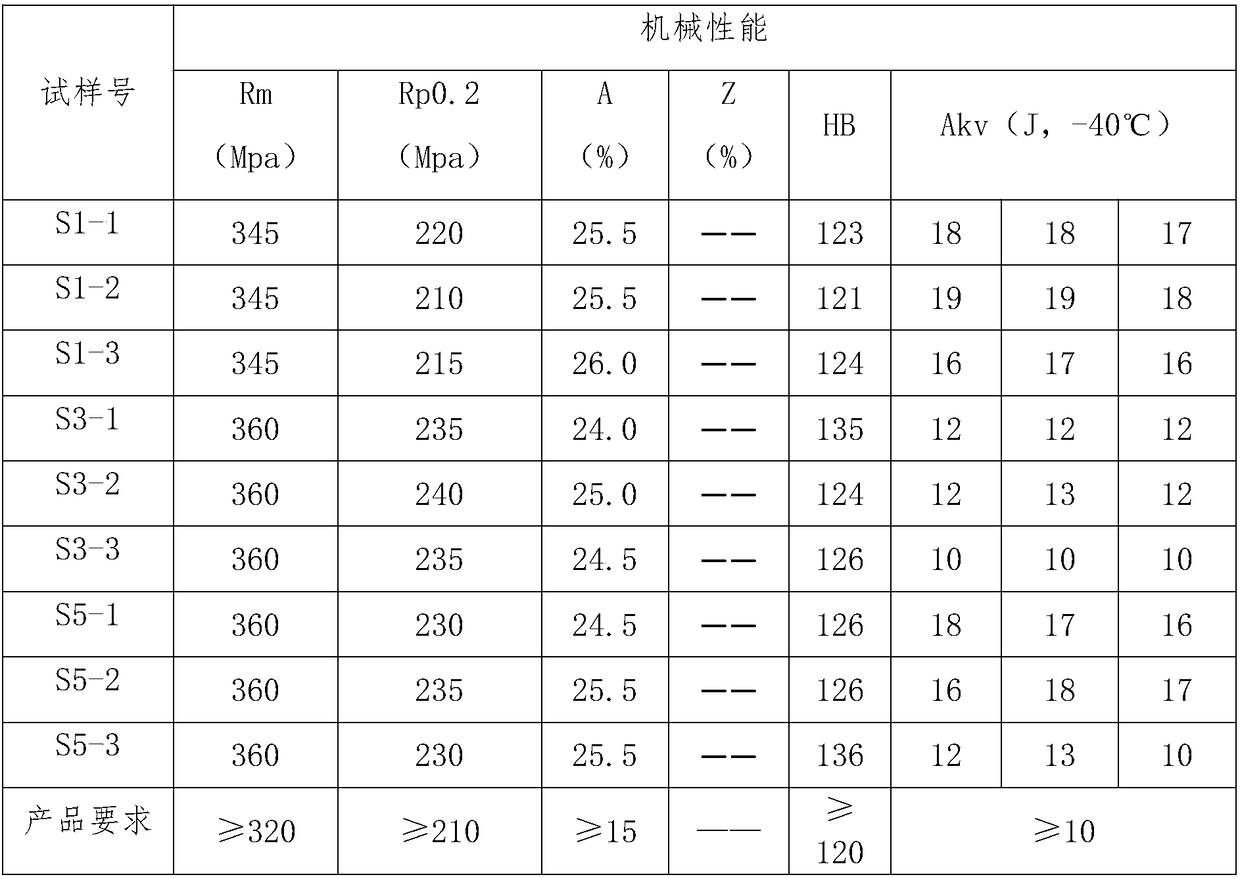

Embodiment 1

[0023] Embodiment 1: a casting method of low-temperature impact-resistant nodular cast iron material, comprising the following steps:

[0024] 1. Molding: Molding is made with molding sand and core sand as molding materials. In this embodiment, the trial-manufactured part is a medium-plate casting with a pouring weight of about 1600Kg and a wall thickness of 80 to 220mm. It is thick ductile iron. Place 4 70mm thick Y-shaped ductile iron standard test blocks for each casting, and 3 pieces for molding, and the molding is carried out according to the process standard.

[0025] The mold is preheated with hot air. The preheating time is 24-36 hours, and the cavity temperature reaches 40-80°C, so as to prevent casting defects and affect the test performance of castings due to excessive gas generation in the cavity during pouring and filling.

[0026] 2. Smelting: Add low-silicon pig iron and scrap steel as smelting raw materials and carburizer to an intermediate frequency induction ...

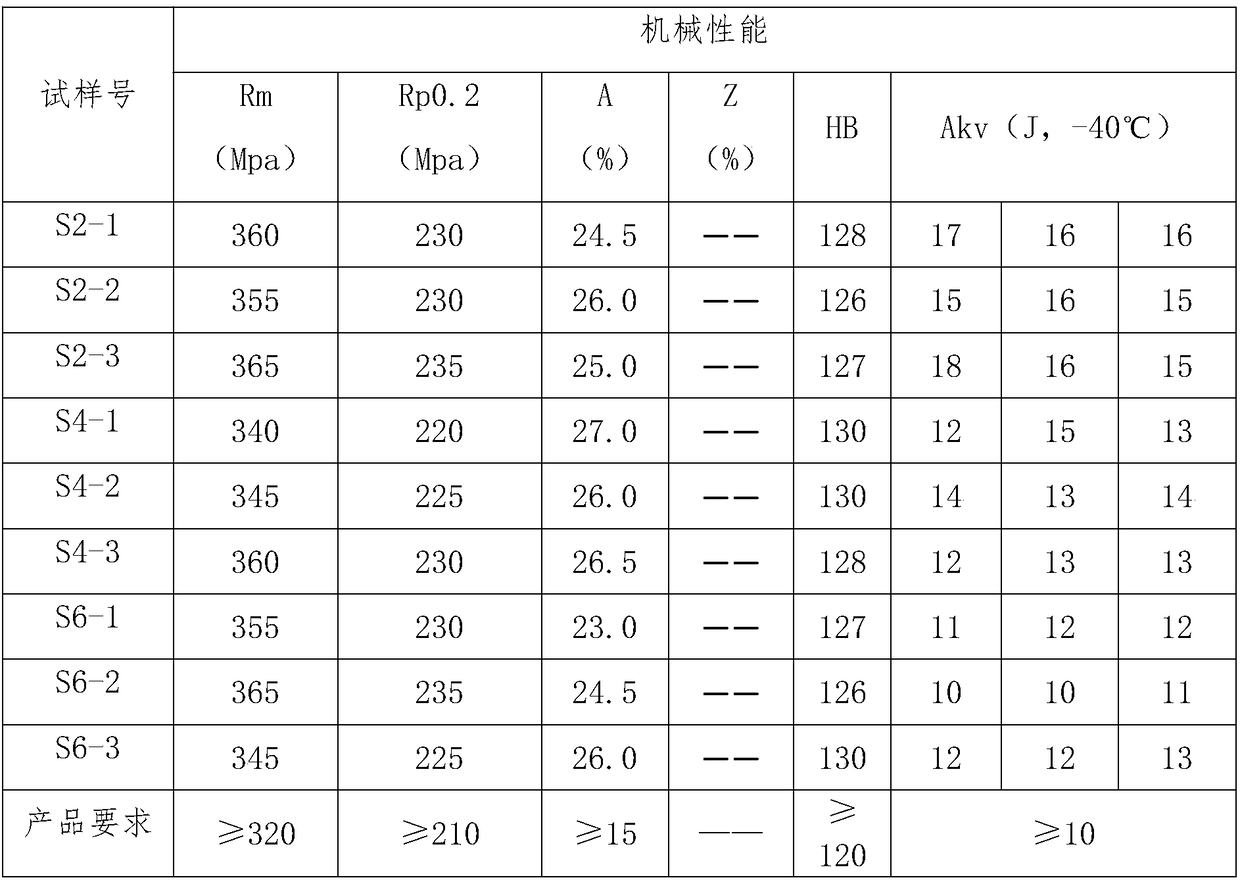

Embodiment 2

[0037] Example 2: Different from Example 1, before the spheroidization treatment, the composition in the furnace is controlled as follows: C 3.85-3.9%, Si 0.55-0.6%, Mn<0.4%, P<0.04%, S<0.03%, The balance is Fe.

[0038] After the inoculation with flow in Step 5 is completed, the composition of molten iron is controlled as follows: C 3.85-3.9%, Si 1.95-2.0%, Mn<0.4%, P<0.04%, S<0.03%, and the balance is Fe.

[0039] The mechanical property test data in this embodiment is as follows table:

[0040]

[0041] It can be seen from the test results that the mechanical properties of the ductile graphite castings cast by the present invention meet the requirements of mechanical properties. Under the low temperature condition of -40°C, the impact performance Akv is greater than 10J, which meets the requirements of wind power materials for low temperature impact resistance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Impact performance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com