Rotatable multi-direction ironing platform for ready-made clothes

An ironing platform and rotary technology, which is applied in the field of ready-made garments, can solve the problems of easily bulging on the surface, secondary wrinkles, and indentation of clothes, so as to reduce equipment occupation, avoid secondary wrinkles, and achieve multifunctional functions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

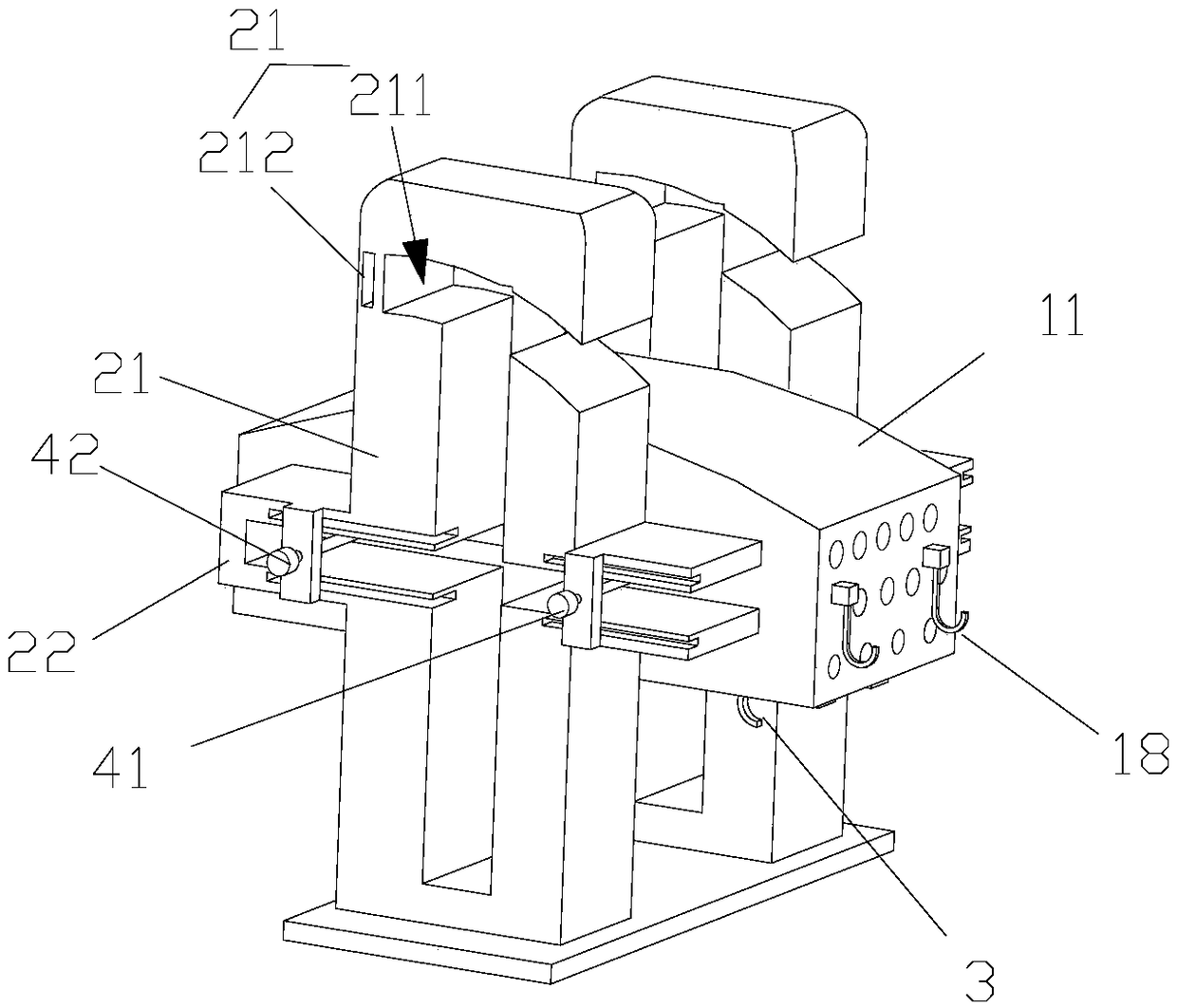

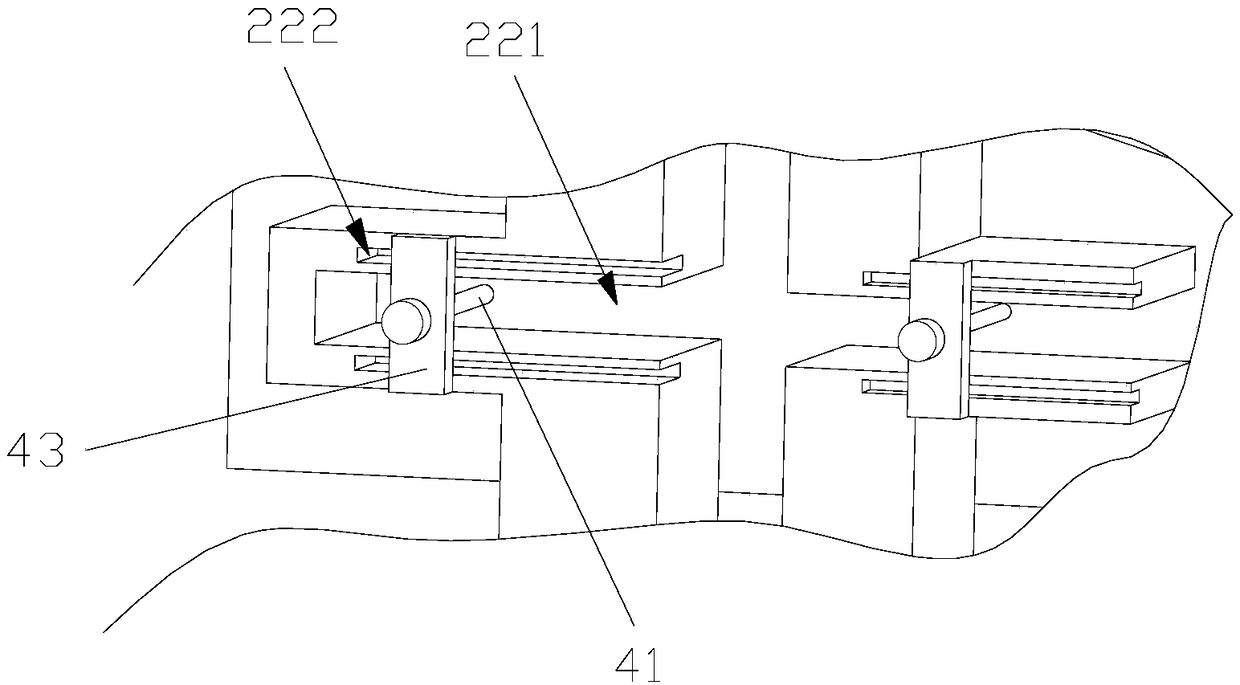

[0036] Such as figure 1 , 2 As shown, the present invention discloses a rotatable multi-directional clothing ironing platform, which includes an ironing board 1 and a support frame 2, and the ironing board 1 is pivotally connected to the support frame 2 through fasteners. One of the upper and lower sides of the ironing board 1 is a curved surface 11 , and the other is a horizontal surface 12 . A first hook 3 is arranged on the horizontal plane 12 . The support frame 2 includes support columns symmetrically arranged on the left and right sides of the ironing board 1 , and each support column is a cross structure, including a vertical plate 21 and a horizontal plate 22 . Such as image 3 As shown, the horizontal plate 22 is provided with an opening groove 221 and a slide groove 222 parallel to the opening groove 221. The guiding direction of the opening groove 221 is parallel to the length direction of the horizontal plate 22 and the starting end of the opening groove 221 is ...

Embodiment 2

[0043] Such as Figure 8-10 As shown, the difference between this embodiment and the above embodiments is that the connecting shaft 411 is a screw rod, and the inserting block 413 cooperates with the connecting shaft 411 through a screw sleeve (not shown in the figure). Or, the inserting block 413 and the connecting shaft 411 are clearance fit, and the upper clamping spring plate 213 and the lower clamping spring plate 214 arranged in the up and down direction are arranged in the chute 222 and the slot 212, and the end of the inserting block 413 can clamp Hold between the upper clamping spring plate 213 and the lower clamping spring plate 214.

[0044] When the connecting shaft 411 is a screw rod, the axial movement of the inserting block 413 along the connecting shaft 411 can be realized by rotating the other side of the screw rod, so as to realize the engagement or separation of the inserting block 413 with the chute 222 and the slot 212 . When the connecting shaft 411 is a...

Embodiment 3

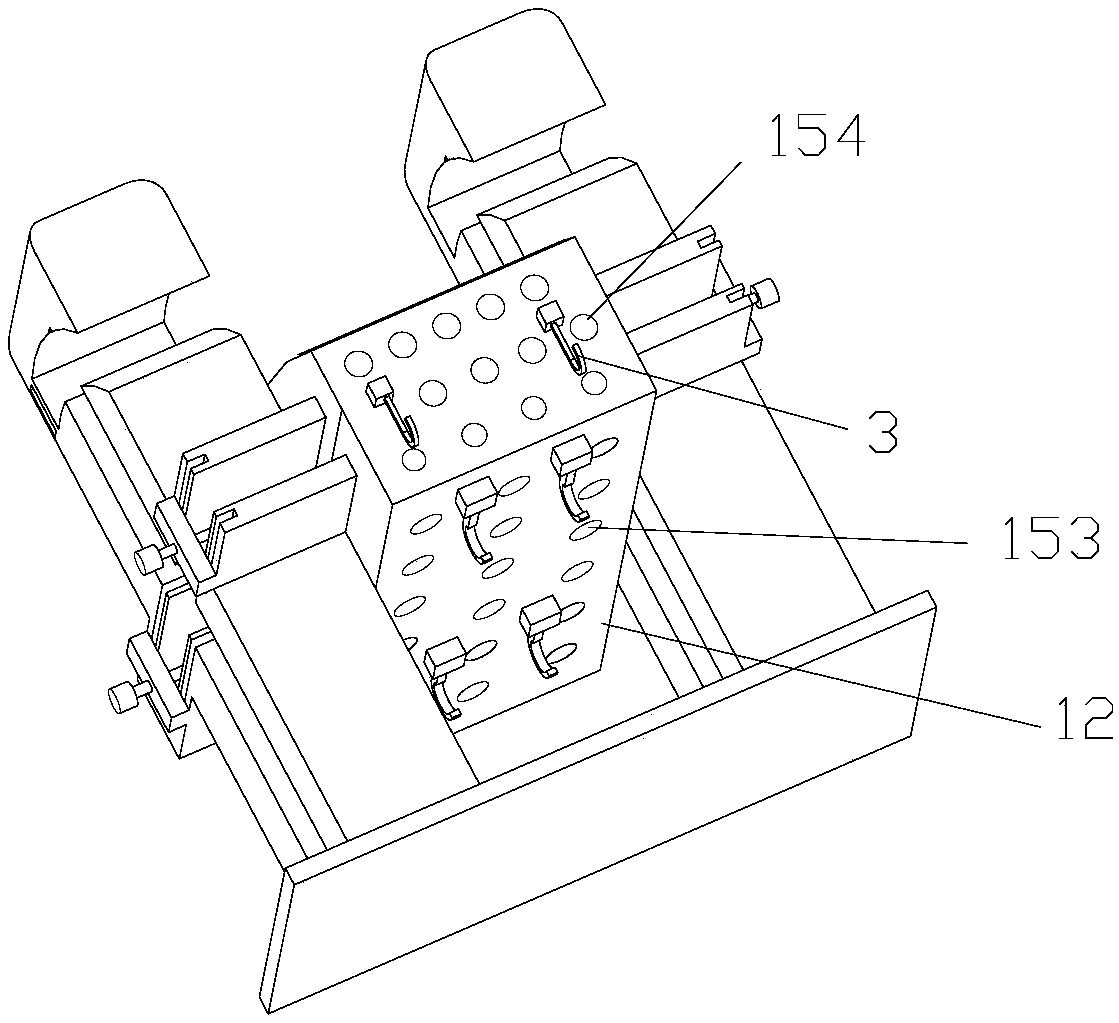

[0046] Such as figure 2 , 6 , 7, and 11, the difference between this embodiment and the above-mentioned embodiments is that an airflow channel 151 is opened in the inner cavity of the ironing board 1, and an air inlet is opened on the surface of the ironing board 1 (not shown in the figure). Drawing), a first air outlet 153 is opened on the horizontal plane 12, and a second air outlet 154 is opened on the front and rear sides of the ironing board 1. The air inlet, the first air outlet 153 and the second air outlet 154 are all in communication with the air passage 151 . Second hooks 18 are also arranged on the front and rear surfaces of the ironing board 1 . It also includes a first seal (not shown) for blocking the first air outlet 153 and a second seal (not shown) for blocking the second air outlet 154 .

[0047] After ironing, clothes need to be dried to control their moisture regain. The present invention adopts the mode of air blowing to take away the water vapor on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com