Cement concrete pavement crack damage grooving type repair method

A technology of cement concrete and concrete pavement, which is applied in the direction of road repair, road, road, etc., can solve the problems of long time consumption and poor repair effect, and achieve the effect of improved durability, small joints and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The concrete surface repair method proposed by the present invention will be further described in detail below in conjunction with embodiments.

[0018] According to the following description and claims, the advantages and features of the present invention will be clearer:

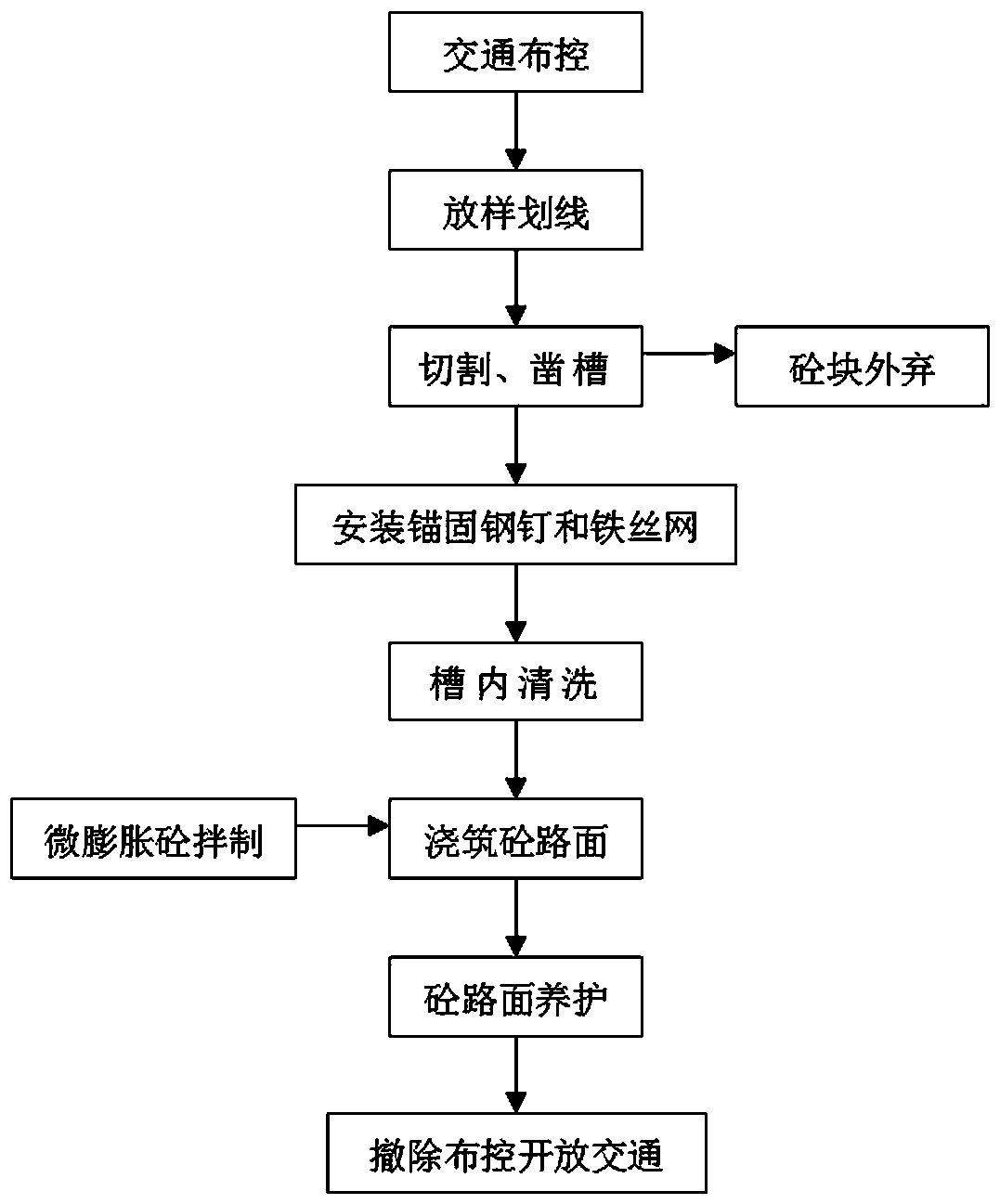

[0019] A method for repairing cracks and damages on cement concrete pavement by chiseling grooves, including the following steps: traffic control→staking out and marking→cutting and chiseling→installation of anchor steel nails and wire mesh→cleaning in the groove→concrete pavement→concrete road maintenance→removal and opening traffic.

[0020] Step 1: Traffic deployment control. To ensure construction safety and smooth traffic, the repair of the longitudinal joints of the concrete pavement requires traffic deployment control. Deploy eye-catching traffic diversion signs and construction reminders 100m in front of the repair location, and extend them to the repair location with reflective cones; place cemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com