Waterproof device suitable for expansion joint of railway bridge of existing railway lines

A waterproof device and expansion joint technology, which is applied in bridges, bridge parts, bridge construction, etc., can solve the problem of small clamping force between porous waterproof rubber belt and anchor profiles, weak ability to change the gap of porous waterproof rubber belt, waterproof rubber With problems such as poor adaptability to telescopic deformation, it achieves the effect of improving adaptability to telescopic deformation, easy operation and implementation, and high clamping force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

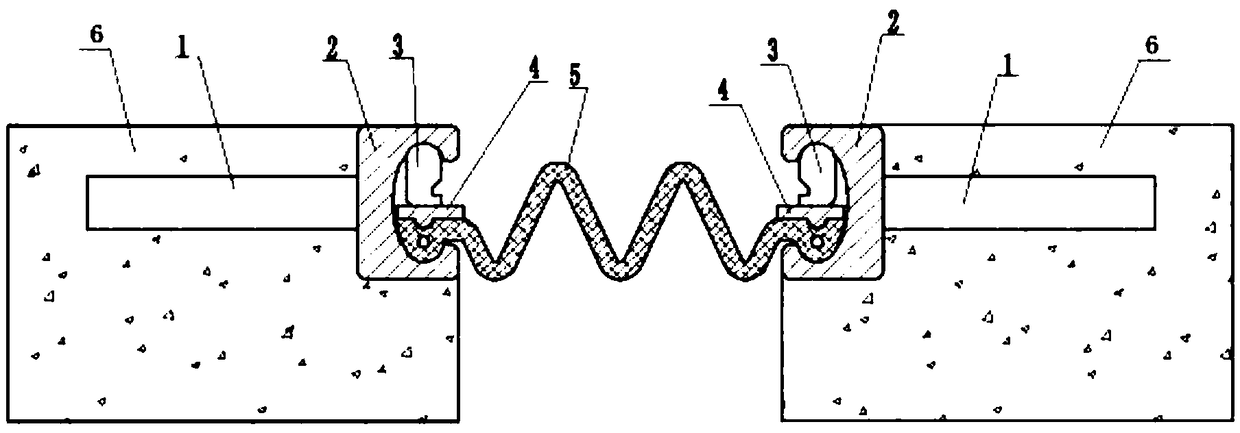

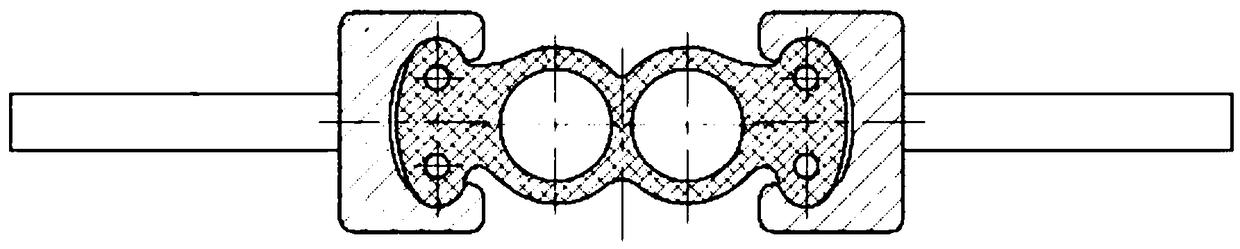

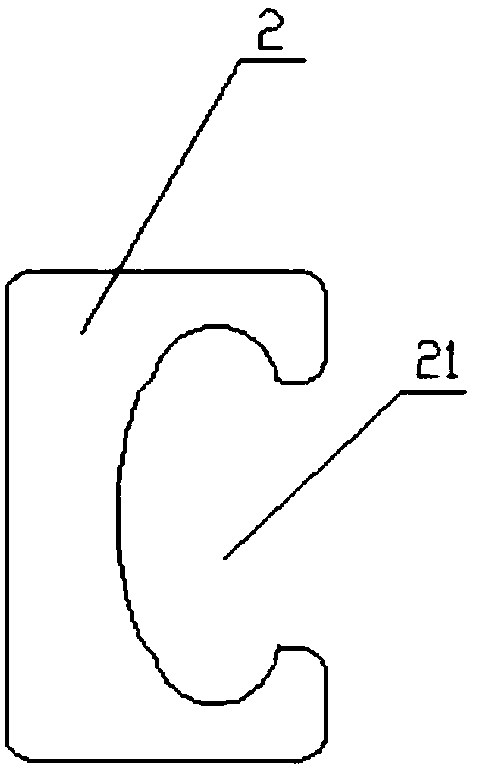

[0028] like figure 1 , Figure 3-6 As shown, a kind of waterproof device applicable to the expansion joints of existing railway bridges in this embodiment includes anchoring steel bars 1, anchoring profiles 2, and waterproof rubber belts 5. The anchoring steel bar 1 is fixedly connected, and the waterproof rubber belt 5 is arranged between the symmetrically arranged anchoring profiles 2 . The anchoring profile 2 has a cavity 21 inside, and the opening of the cavity 21 is C-shaped, and the cavity 21 is provided with a pressing block 3 and a pressing plate 4 . The waterproof rubber belt 5 includes two connecting ear straps 51 on the outside and a telescopic body 52 arranged between the two connecting ear straps 51. The two connecting ear straps 51 are fixed in the cavity 21 by the briquetting block 3 and the pressing plate 4 and are anchored together. The profile 2 forms a sealed structure. Specifically, a concave arc 53 is provided on the top surface of the connecting ear b...

Embodiment 2

[0031] Embodiment 1 is applicable to the waterproof device of the existing railway bridge expansion joint, and the concrete installation process is as follows: Wherein, Figure 7 It is the first step assembly diagram of the waterproof device; Figure 8 is the second step assembly diagram of the waterproof device, figure 1 It is a schematic diagram of the waterproof device after assembly.

[0032] The first step: clean the cavity 21 of the anchoring profile, insert the connecting ear strap 51 of the waterproof rubber belt 5 into the cavity 21, and then put it into the pressure plate 4, and the protrusion 41 of the pressure plate 4 cooperates with the concave arc 53 of the connecting ear strap 5 ;

[0033] Step 2: Rotate the pressing block 3, the top is against the upper part of the cavity 21, and the arc transition area of the lower part is in contact with the upper surface of the pressing plate 4;

[0034] Step 3: Use special tooling to act in the groove 31 on the side o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com