A method for spirally ascending stacking of phosphogypsum storage

A spiral rising and phosphogypsum technology, which is applied in construction, infrastructure engineering, protective devices, etc., can solve the problems of high cost of phosphogypsum excavation and dam construction, difficulty in laying HDPE geomembrane, etc., and reduce the total cost of construction and operation , the effect of increasing the deposition time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

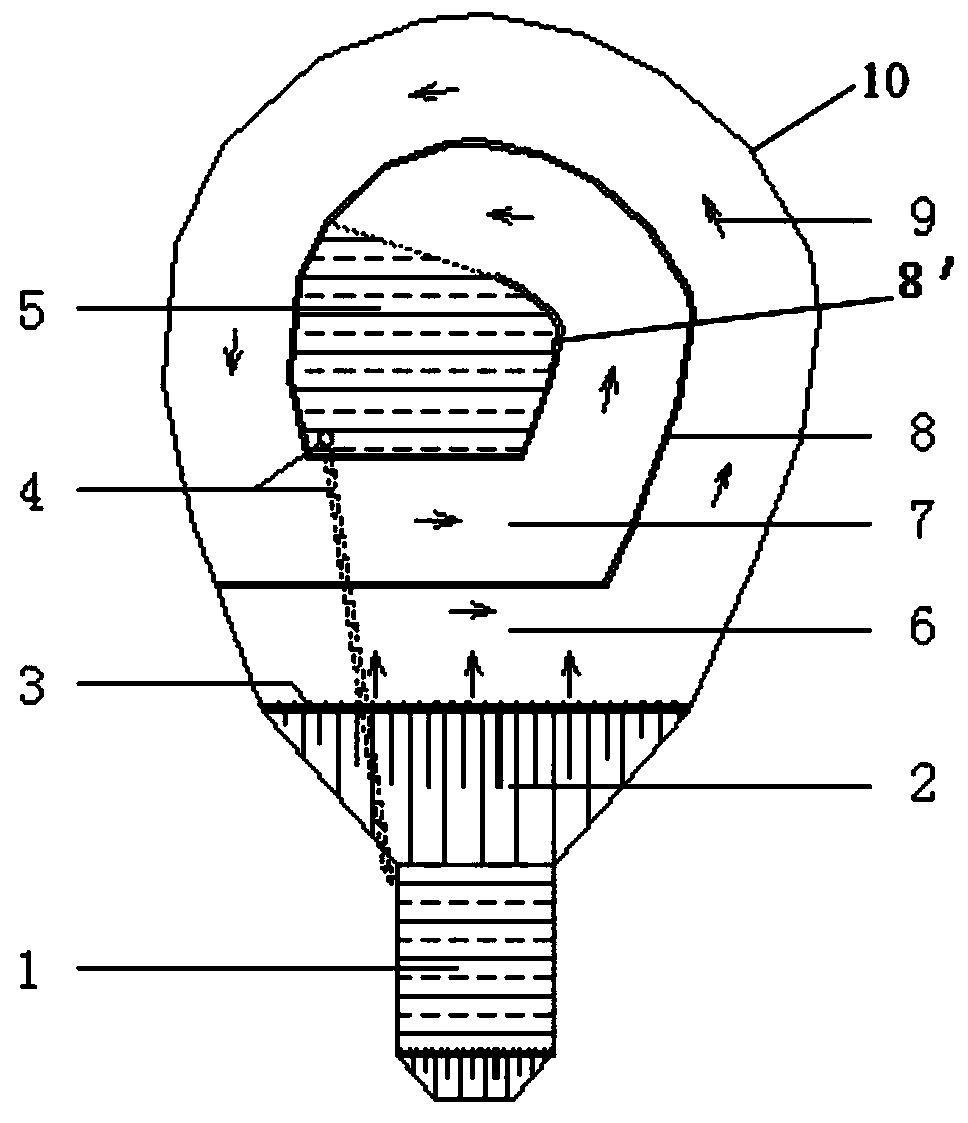

[0021] In order to better describe the present invention, a spiral ascending stacking method of a phosphogypsum storehouse according to the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0022] Take a valley-type wet storage phosphogypsum warehouse as an example. The present invention relates to a method for spirally ascending stacking of phosphogypsum silo. The downstream method is adopted to build a phosphogypsum dam 2, and a slurry discharge pipe 3 is arranged before the crest of the phosphogypsum dam 2, and the phosphogypsum slurry passes through the slurry discharge pipe 3 in the phosphogypsum The dam crest of dam 2 discharges evenly into the reservoir. A spiral dam is set in the phosphogypsum reservoir, and the spiral dam is formed by connecting the minimum dry beach dam 8 and the flood control dry beach dam 8 ', and the minimum dry beach dam 8 is separated from the phosphogypsum dam In front of the dam of 2,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com