Lifting method of high-rise steel structure columns

A hoisting method and steel structure technology, which is applied in the direction of building construction, building material processing, construction, etc., can solve problems such as time-consuming and laborious, easy to shake, and inaccurate positioning, so as to avoid potential safety hazards, reduce shaking, and improve accuracy. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below with reference to the accompanying drawings.

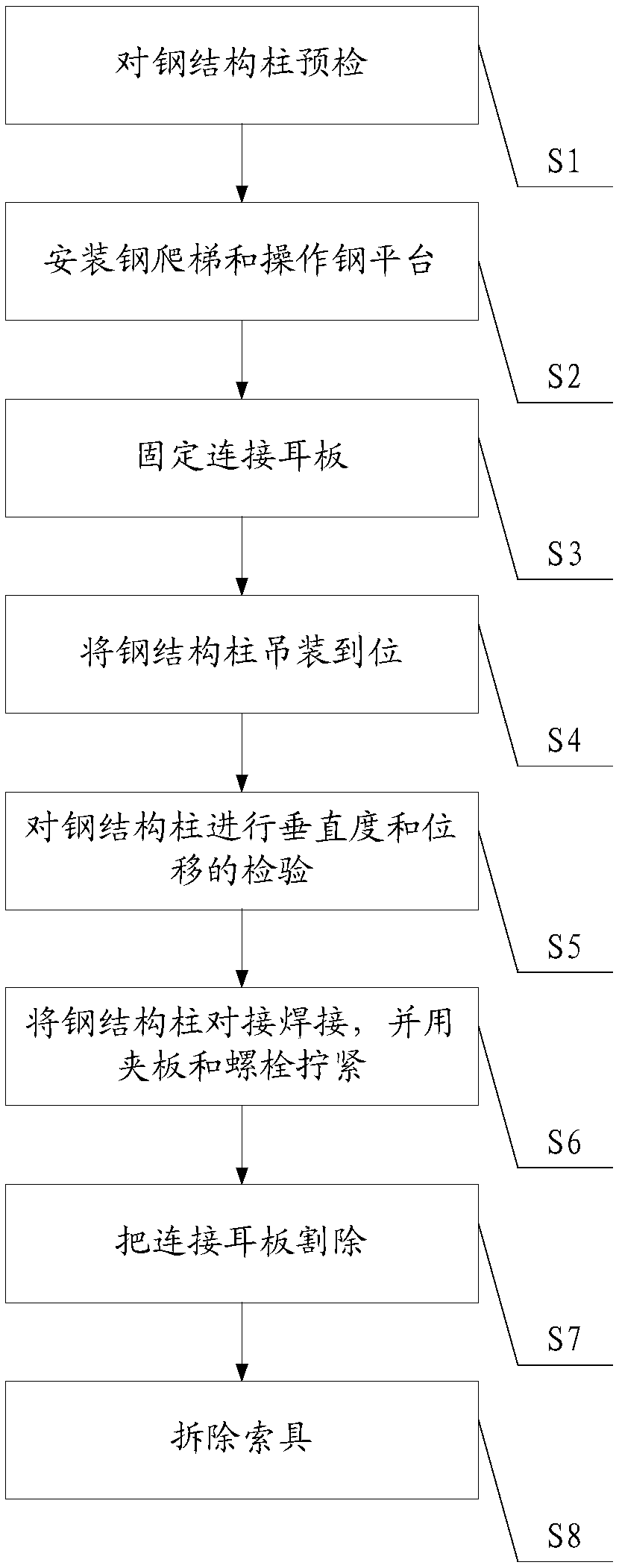

[0022] see figure 1 , the hoisting method of the high-rise steel structure column of the present invention comprises the following steps:

[0023] Step S1, pre-check the length, section, side bend and elevation of the corbel surface of the steel structure column, report any problems found, and take measures to solve them. At the same time, the elevation and axis of the substructure shall be re-examined before the installation of the steel structure column.

[0024] Step S2, install the steel ladder and operate the steel platform. Before hoisting, the steel ladder should be installed on the steel column on the ground for the climbing operation. The outside is the operating steel platform set at the joint position with the upper column, which should also be installed on the steel column on the ground.

[0025] In step S3, connecting lugs are fixed on the four sides of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com