Lining trolley, and formwork erecting and releasing methods thereof

A technology for lining trolleys and formwork, which is applied in wellbore lining, tunnel lining, earth-moving drilling and mining, etc., can solve the problems of high labor intensity, long time for erecting and demoulding, low accuracy, etc. The effect of reducing the number and simplifying the overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

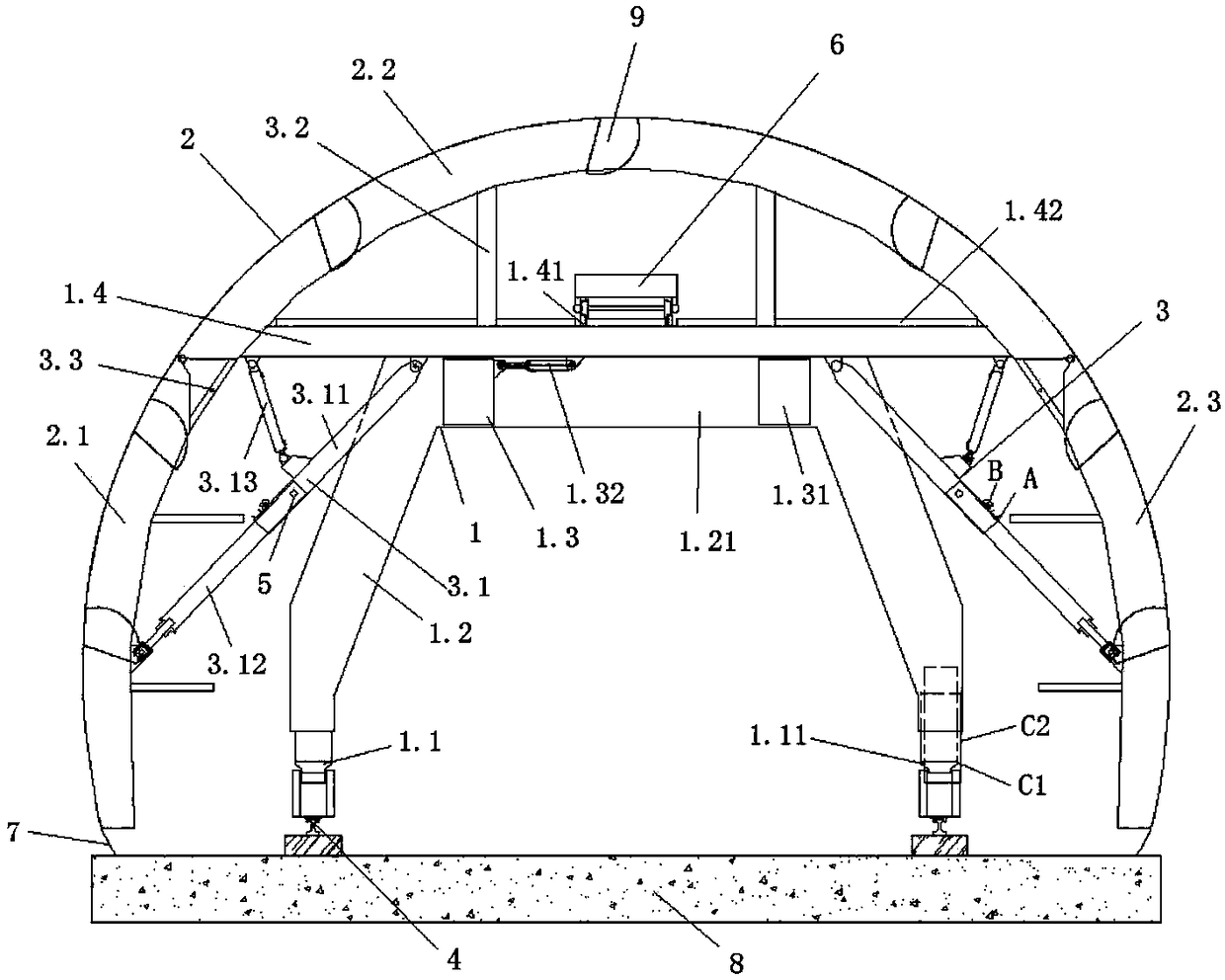

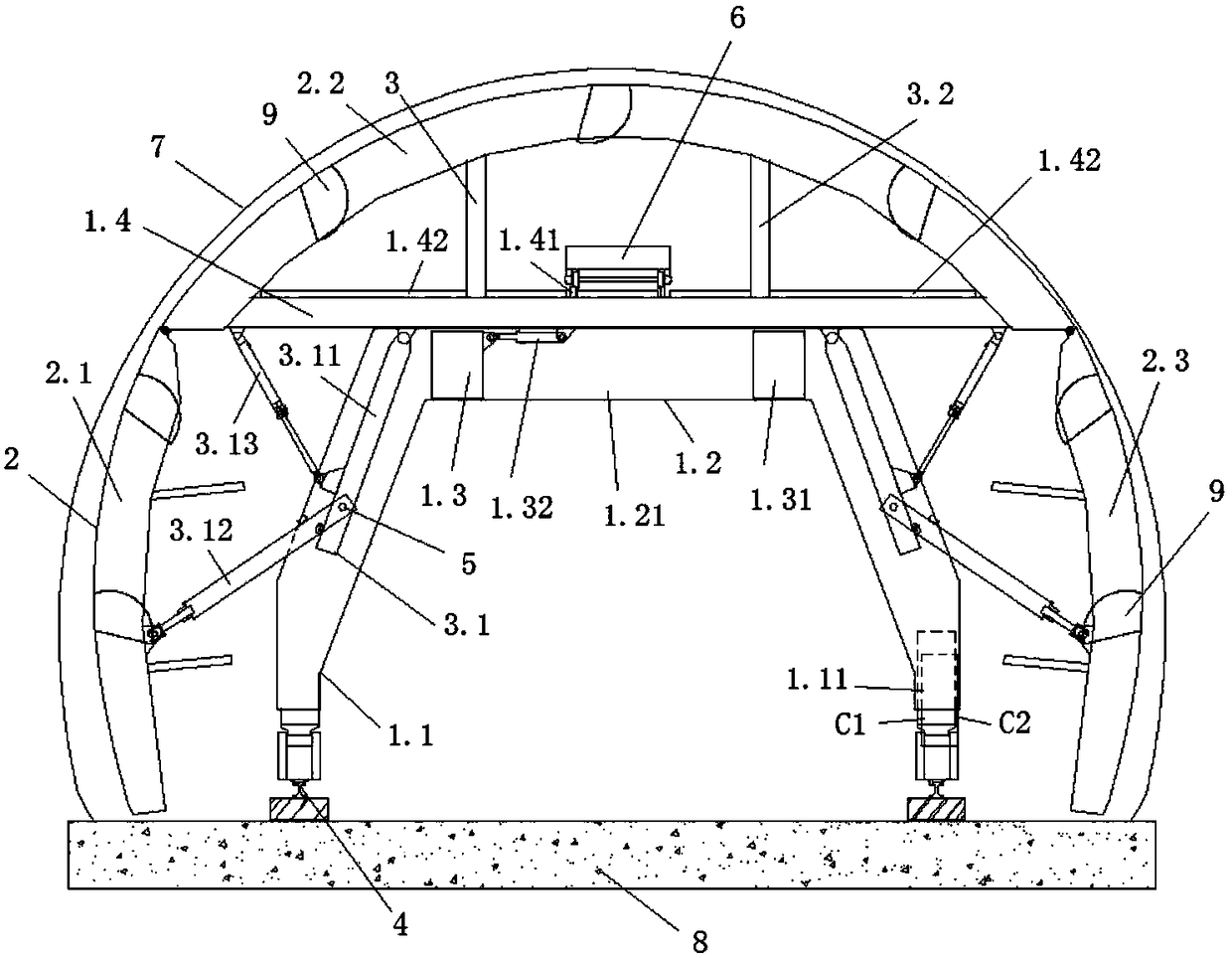

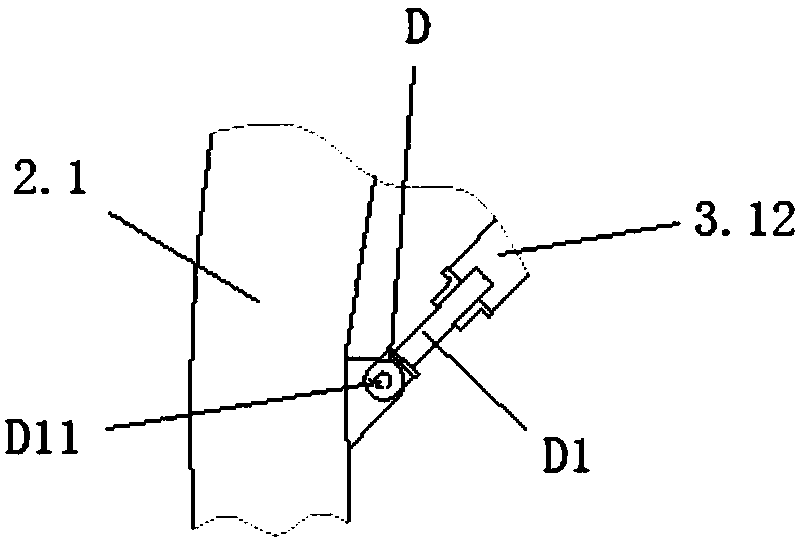

[0064] see figure 1 and figure 2 A lining trolley includes a gantry system 1, a formwork system 2, a connecting assembly 3 connecting the gantry system 1 and the formwork system 2, and a traveling mechanism 4 for driving the entire lining trolley to travel.

[0065] The gantry system 1 includes a telescopic column assembly 1.1, an inverted U-shaped gantry beam set 1.2, a gantry longitudinal beam set 1.3, and brackets arranged on the gantry beam set 1.2 and / or the gantry longitudinal beam set 1.3 Frame beam group 1.4, the details are:

[0066] The telescopic column assembly 1.1 includes four sets of telescopic column single pieces 1.11 (here, other even groups exceeding four groups can also be used), and the telescopic column single piece 1.11 includes a guide column C1, which is sleeved on the guide column C1 The guide sleeve C2 on the top and the two ends are respectively connected to the guide column C1 and the guide sleeve C2, and the lifting mechanism is telescopic alon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com