Automatic mineral powder rod filling instrument

A rod filling instrument and fully automatic technology, which is applied in the field of automatic mineral powder rod filling instrument, can solve the problems of high labor intensity, destroying carbon rods, and wasting labor, and achieves reduced labor intensity, high rod filling efficiency, and wide application range. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

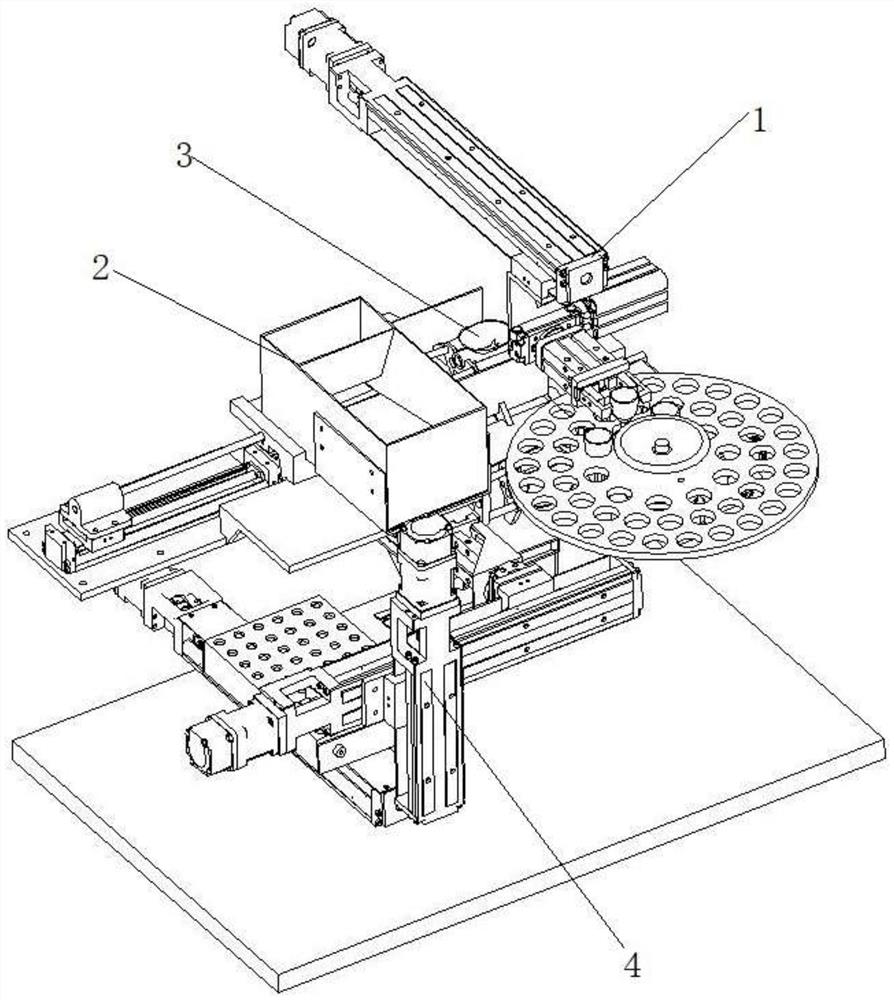

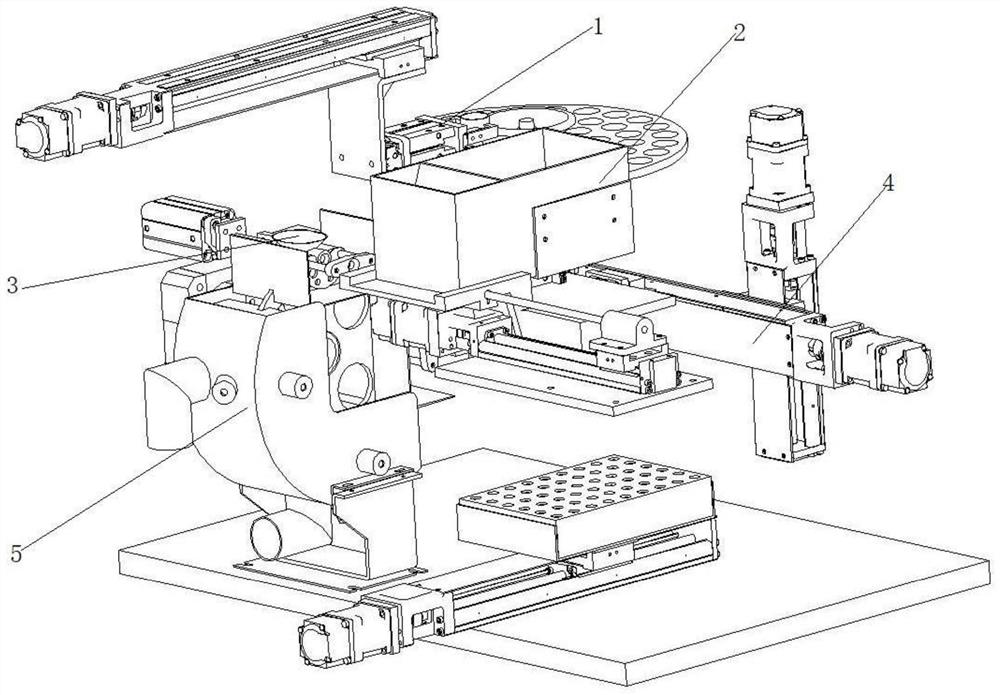

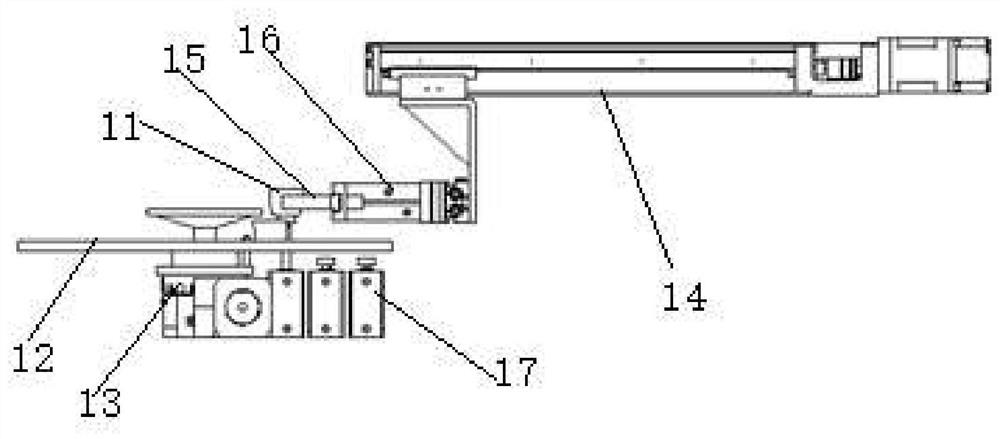

[0050] A fully automatic mineral powder rod filling instrument, including a controller (usually a PLC controller, or a single-chip microcomputer, used to realize the linkage between modules, the preset and adjustment of the driving element) and the filler connected to the controller Module 3, material dumping module 1, rod pushing module 2 and rod taking module 4, filling module 3 includes turntable 31, filler rod 32 and filler rod driving mechanism 33, and several stations with filler hoppers 34 are arranged on the turntable 31 , the bottom surface of the filler hopper 34 is provided with a powder collecting tank 341, and the two ends of the powder collecting tank 341 are opened and extended to form a filler rod hole 342 and a carbon rod hole 343 respectively. Crucible 11 (different crucibles 11 are placed with the same or different mineral powders, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com