A compatible electric energy meter automation calibrating device with belt lines and a method

An automatic verification and electric energy meter technology, applied in the field of electric measurement, can solve the problems of inability to realize the verification of various types of electric energy meters, low efficiency, large floor space and space, etc., to facilitate transfer and transportation, and improve the verification efficiency. , to avoid inconvenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

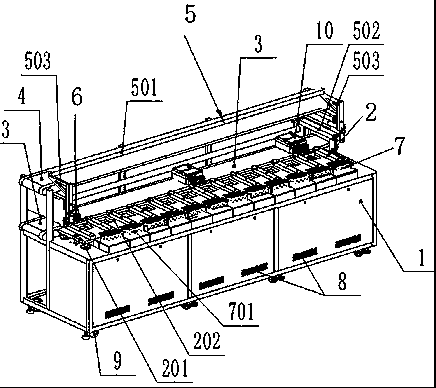

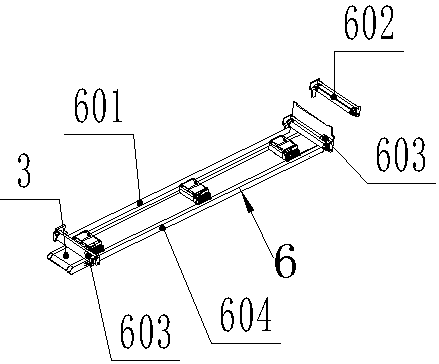

[0057] This embodiment is an embodiment in which the electric energy meter flows into the verification device from the first belt line 3. In this embodiment, the first belt line 3 is usually connected to the electric energy meter verification assembly line. When the smart electric energy meter 10 is verified, pass The roller line of the electric energy meter verification assembly line transmits the smart electric energy meter 10 to the first belt line 3, and the first dial mechanism 6 (refer to image 3 with Figure 8 ) Under the action of the first dial cylinder 602, the first dial lever 601 starts to work, and the first dial lever 601 is on one side of the first belt line 3, so that the smart electric energy meter 10 on the first belt line 3 In close contact with the inner side of the first dial lever 601, start the first dial lever 601, then the first dial lever 601 will stretch toward the dial position unit 202 of the electric energy meter verification device, and the smar...

Embodiment 2

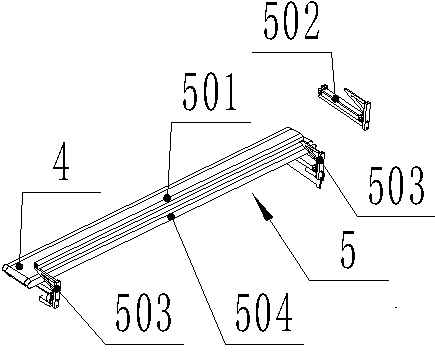

[0059] This embodiment is the implementation process of transferring the intelligent electric energy meter 10 after the detection from the electric energy meter verification device to the second belt line 4, refer to figure 2 with Figure 9 , after the smart energy meter 10 verification is completed in embodiment 1, the automatic wiring and wire removal device 7 carries out the automatic wire removal work, and the compatible electric energy meter is connected to the table seat 701 to unclamp the connecting terminal of the smart energy meter 10, and the jacking mechanism 2 Start to work, under the action of the jacking cylinder 203, the jacking plate 201 drives the detected smart energy meter 10 to move upward until it is flush with the second belt line 4 . Then the jacking mechanism 2 is stationary, and the second dialing mechanism 5 starts to work. The second dialing rod 501 is positioned at one side of the smart electric energy meter 10 on the jacking plate 201. Under the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com