Quickly-dried developer for penetration flaw detection test and penetration flaw detection test method using same

A flaw detection test and developer technology, applied in the directions of developer, electrography, optics, etc., can solve problems such as unbalanced suction of penetrating liquid, difficulty in accurately detecting the position of opening defect, uneven developer layer, etc., to achieve coating Excellent fabric workability

Active Publication Date: 2018-11-13

MARKTEC CORP

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0008] However, with the ultra-fast drying method, since the drying is fast, there is a problem that the coating operation must be performed quickly and it is difficult to form a uniform developer layer

[0009] When the developer layer is uneven, the voids between the developer particles are uneven, or there are no voids at all, it is difficult to accurately detect the position of the opening defect because the penetrating liquid is sucked out unevenly or not at all. size

[0010] In addition, even if it is a quick-drying type, it is impossible to perform flaw detection before waiting for drying, and there is also a problem that it is difficult to distinguish the coated part because it does not turn white immediately after coating.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

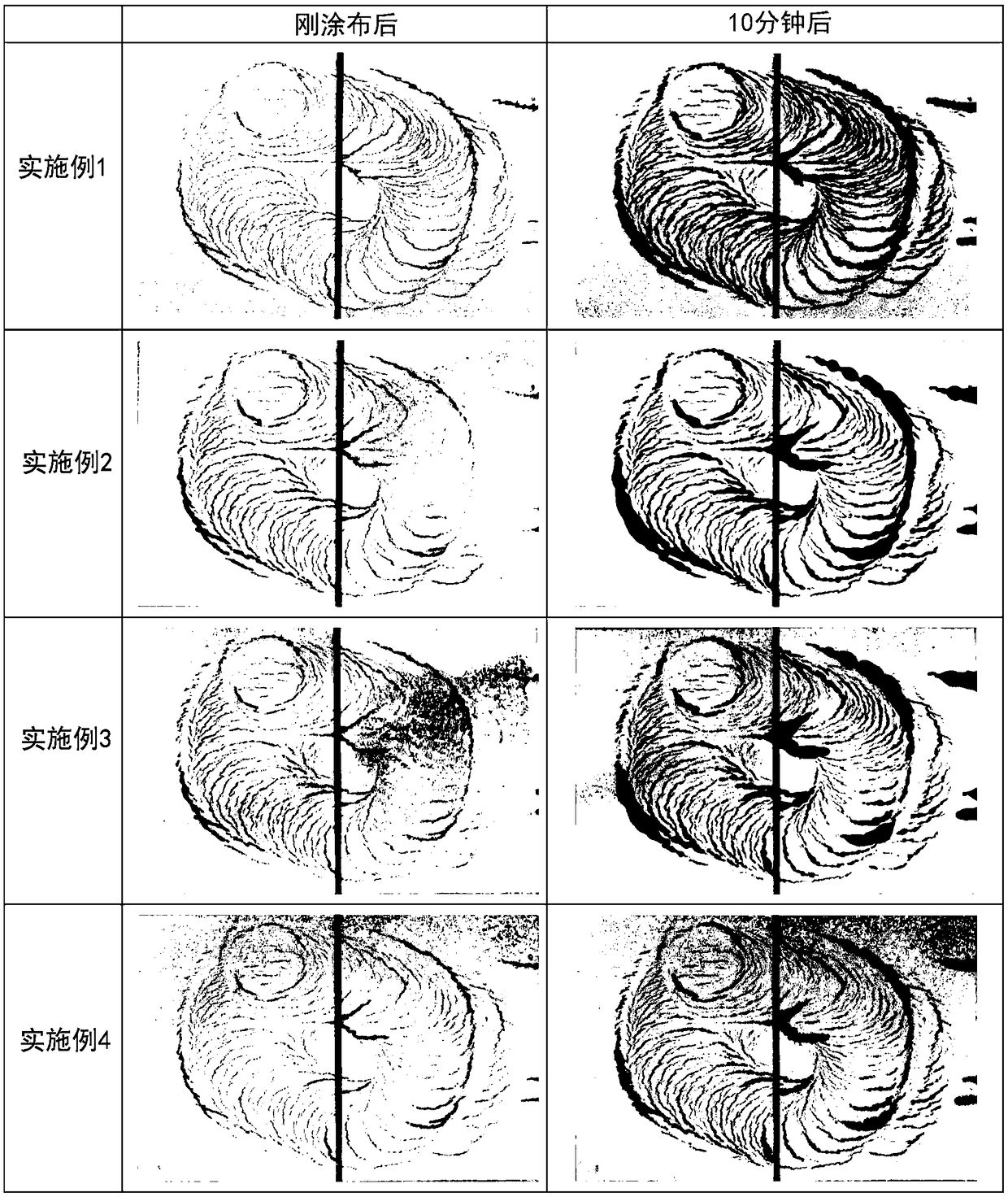

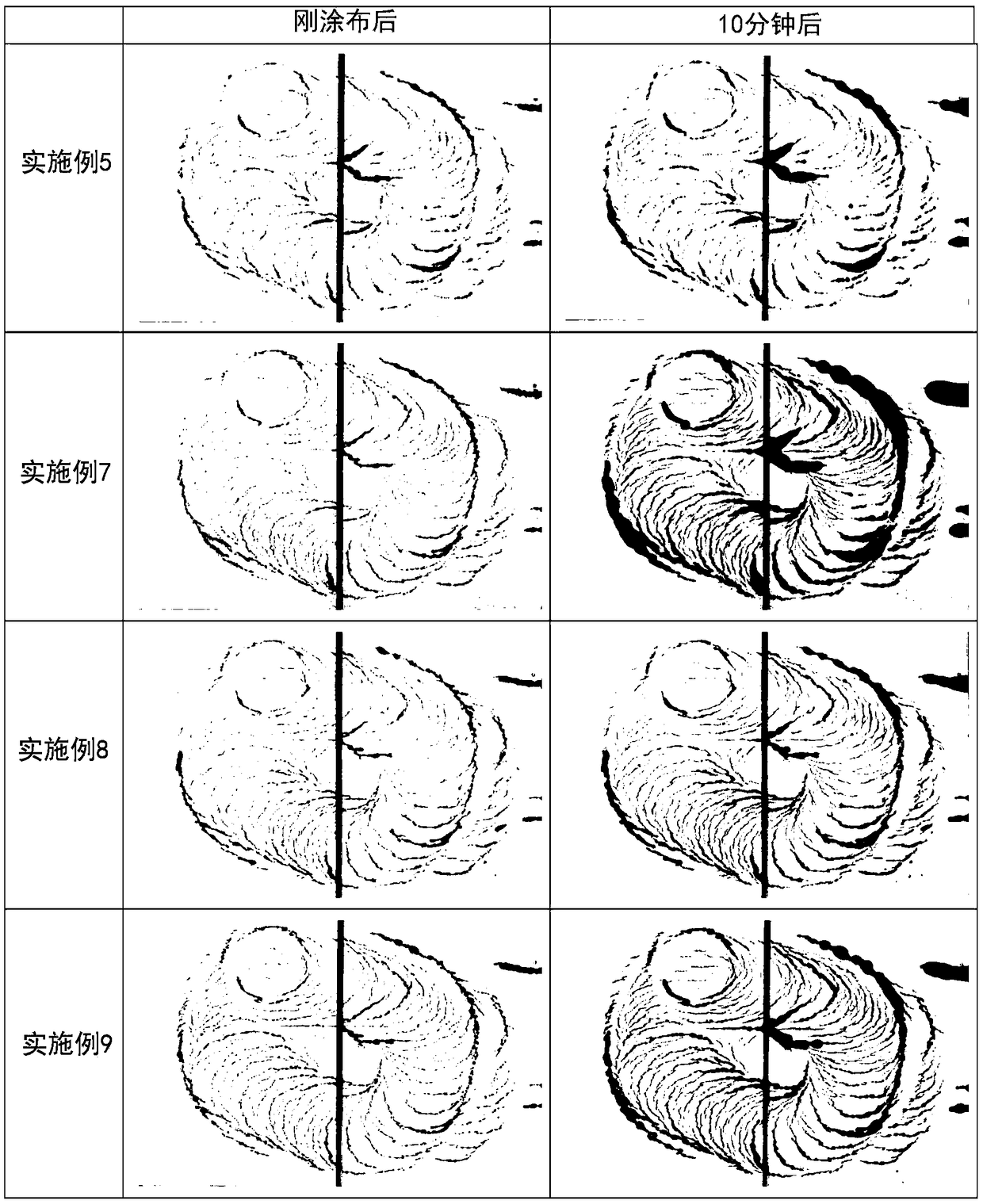

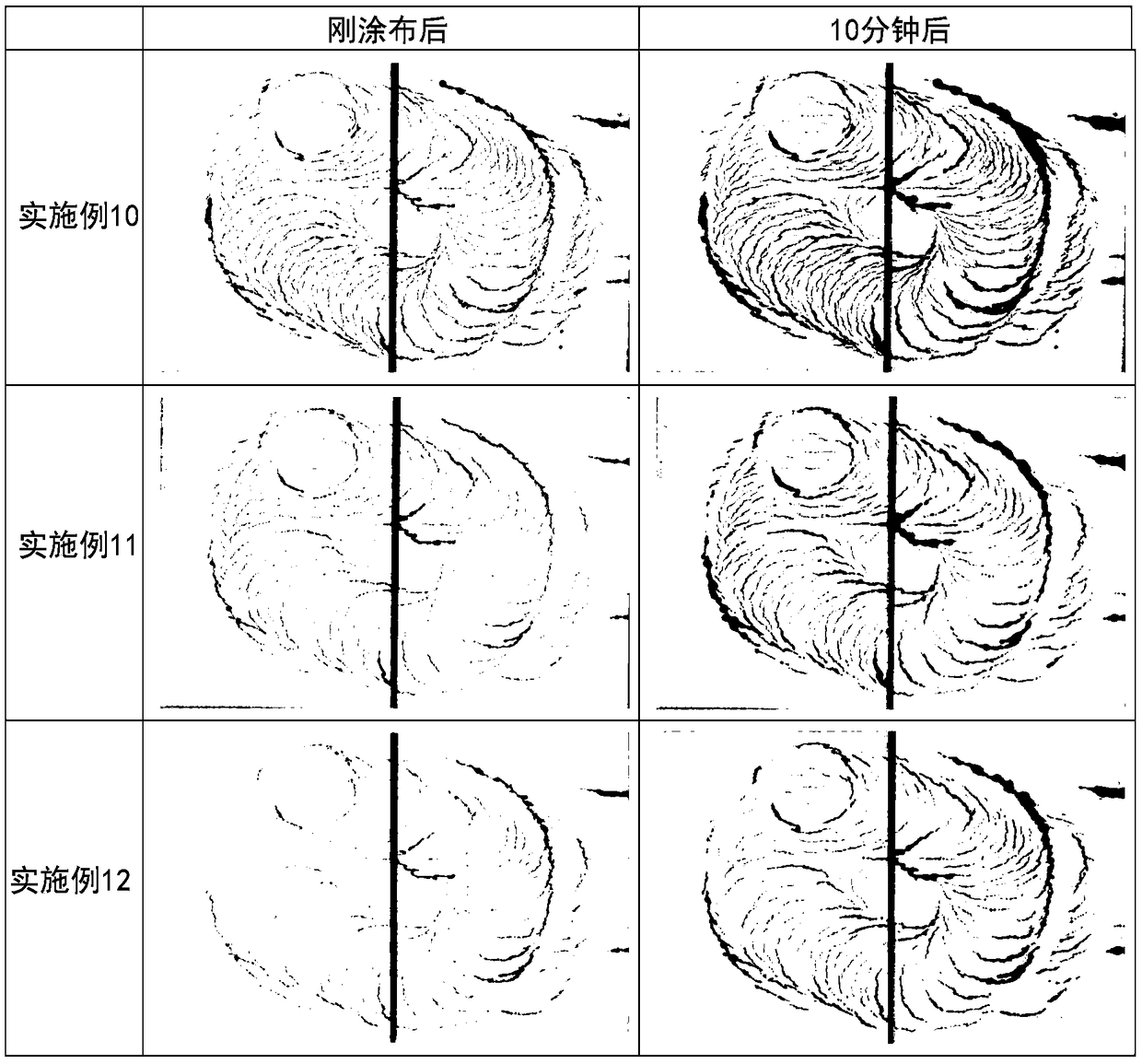

[0064] The present invention will be described in detail with examples and comparative examples, but the present invention is not limited thereto.

[0065] The raw materials described in Table 1 were used to prepare the instant-drying developers of Examples and Comparative Examples of the present invention. The composition is shown in Table 3 and Table 4.

[0066] Table 1

[0067]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

An object of the present invention is to provide a quickly-dried developer. Since a developer layer is whitened immediately after coated with the developer and has concealability, in a penetration flaw detection test using a dying penetration liquid, a clear defect indicating pattern is formed while the developer is not dried so that an open defect portion can be detected and a coated portion canbe visually recognized, so that work efficiency is excellent. In addition, the fine open defect portion can be detected after drying, and a short drying time is achieved. The solution of the present invention is to provide a quickly-dried developer for the penetration flaw detection test, wherein the quickly-dried developer is formed by dispersing 6-20% by weight of titanium oxide and 6-20% by weight of calcium carbonate and / or magnesium carbonate in a volatile organic solvent.

Description

technical field [0001] The present invention relates to a quick-drying developer used in a penetrating flaw detection test for detecting open defects existing on the surface of various metal parts. In detail, it relates to a quick-drying developer for a penetrating flaw detection test as follows: since the developer layer immediately becomes white after coating and has concealment properties, the developer can be used without waiting for the developer to dry. Since a clear defect indication pattern appears, the opening defect can be detected and the coated part can be visually identified, so the work efficiency is excellent, and after drying, the fine opening defect can be detected, and the drying time is short. Background technique [0002] As we all know, the penetrant test is a non-destructive inspection method, which is standardized according to JIS Z 2343-1~6. The basic method is as follows: after the highly penetrable dyeing penetrating liquid or fluorescent penetrati...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G03G9/00

CPCG03G9/00

Inventor 佐伯理惠増田隆秀

Owner MARKTEC CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com