Dynamic modeling method for torsional convex shoulder blade under elastic bearing based on variable section beam

A technology for blade dynamics and dynamic modeling, applied in special data processing applications, instruments, electrical digital data processing, etc., and can solve problems such as dynamic characteristic errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

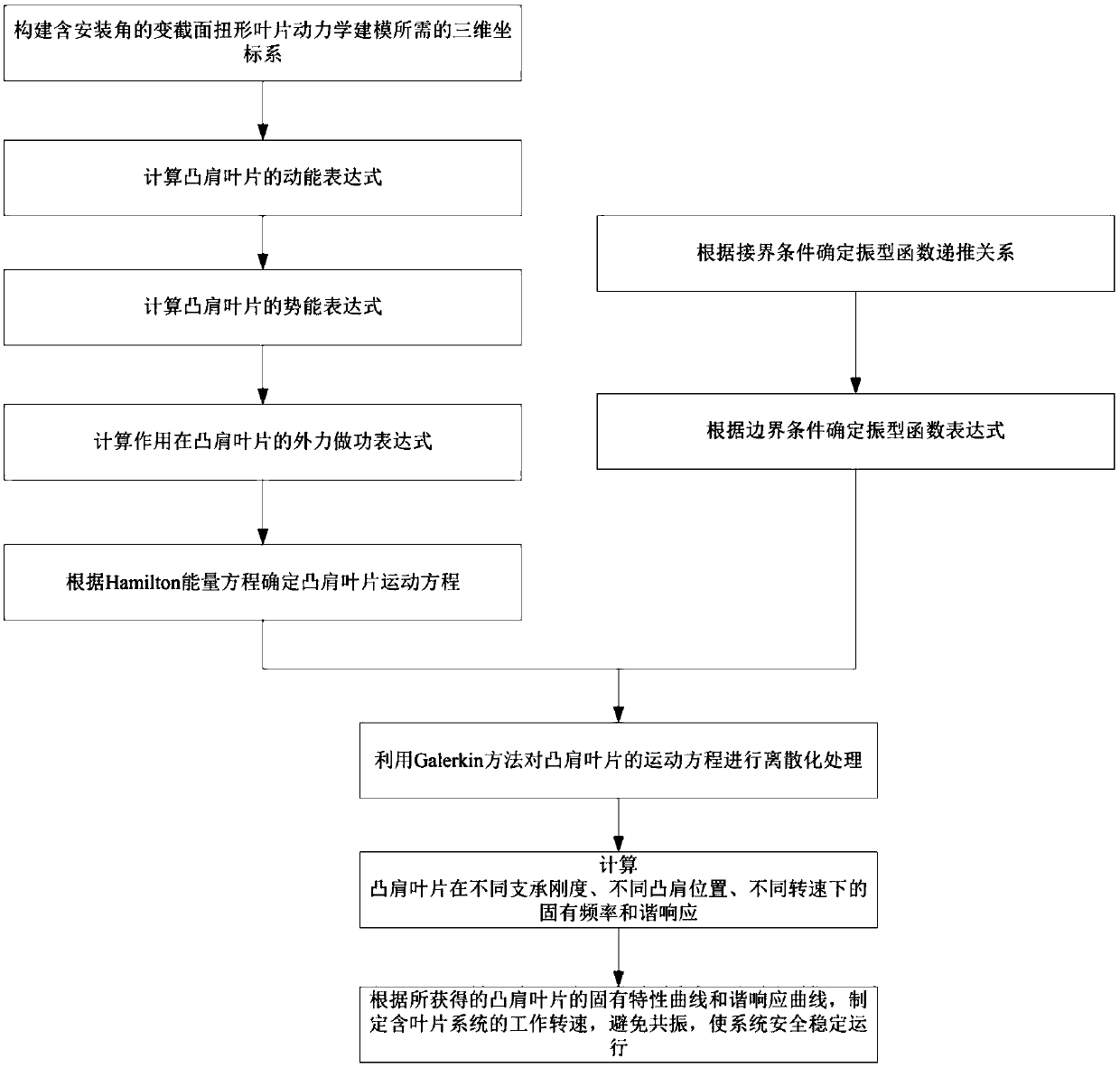

[0089] A dynamic modeling method for twisted shoulder blades under elastic support based on variable-section beams, such as figure 1 shown, including the following steps:

[0090] Step 1: Construct the three-dimensional coordinate system required for dynamic modeling of variable-section twisted blades with installation angles, including: the overall coordinate system OXYZ, and the coordinate system oxyz at the blade root.

[0091] Step 2: Determine the structural parameters and material parameters of the blade, including blade length L, blade width b, blade thickness h, and wheel radius R d , Young's modulus E of blade, Poisson's ratio μ, blade density ρ. Shoulder thickness l 2 , the shoulder width h s ;

[0092] The stiffness k of the restraining spring and the restraining torsion spring of the blade in the bending direction y 、k ry , the stiffness k of the restraining spring and restraining torsion spring of the blade in the swing direction z 、k rz , the installation...

Embodiment 2

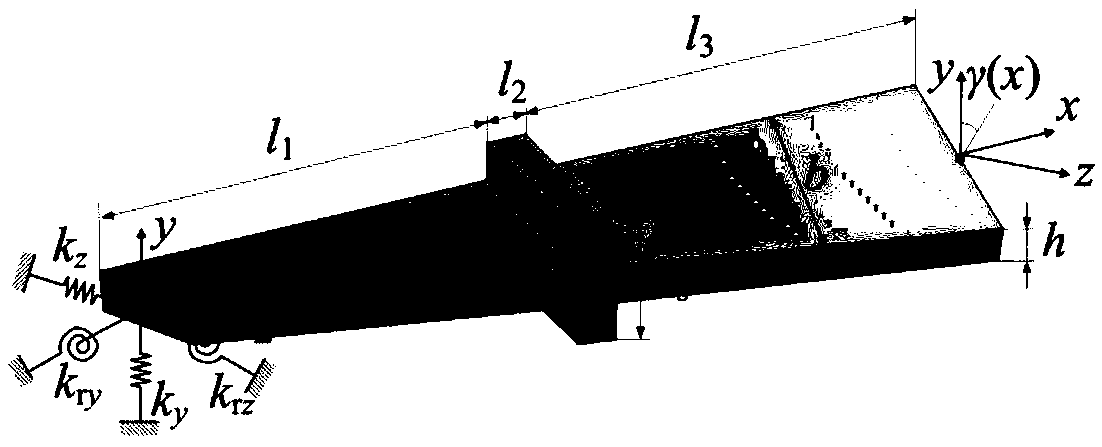

[0151] The schematic diagram of the variable cross-section rotating shoulder blade in the embodiment of the present invention is as follows figure 2 As shown, the dynamic modeling method of the twisted shoulder blade under the condition of elastic support includes the following steps:

[0152] Step 1: Obtain the structural parameters and material parameters of the blade system. The present invention assumes that the blade is an isotropic linear elastic material, and the constitutive relationship satisfies Hooke's law. The relevant parameters of the rotating blade are as shown in Table 1:

[0153] Table 1 Rotating Blade Parameters

[0154]

[0155]

[0156]Step 2: Considering the effect of the pre-twist angle of the plate, determine the displacement vector of any point on the shoulder blade in the global coordinate system OXYZ, and then calculate the kinetic energy expression of the blade:

[0157]

[0158]

[0159] Among them, u, v, w are the deformation of any p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com