Rapid self-locking type energy-saving strain clamp

A tension clamp and self-locking technology, which is applied in the field of fast self-locking energy-saving tension clamps, can solve the problems of difficult work at heights, tools or parts falling, insufficient self-locking tightening force, etc. The effect of high-altitude work difficulty, easy production and processing, and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

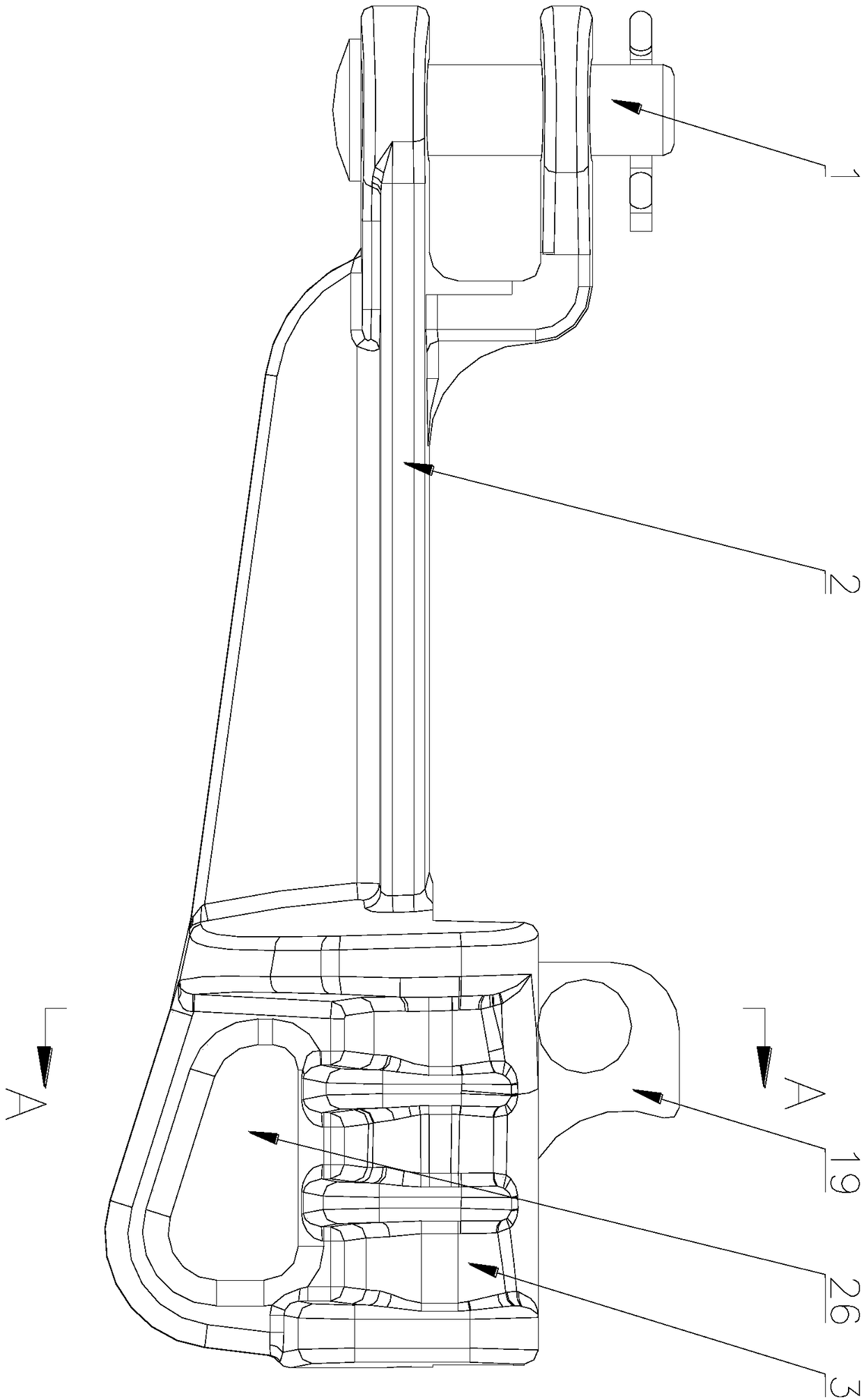

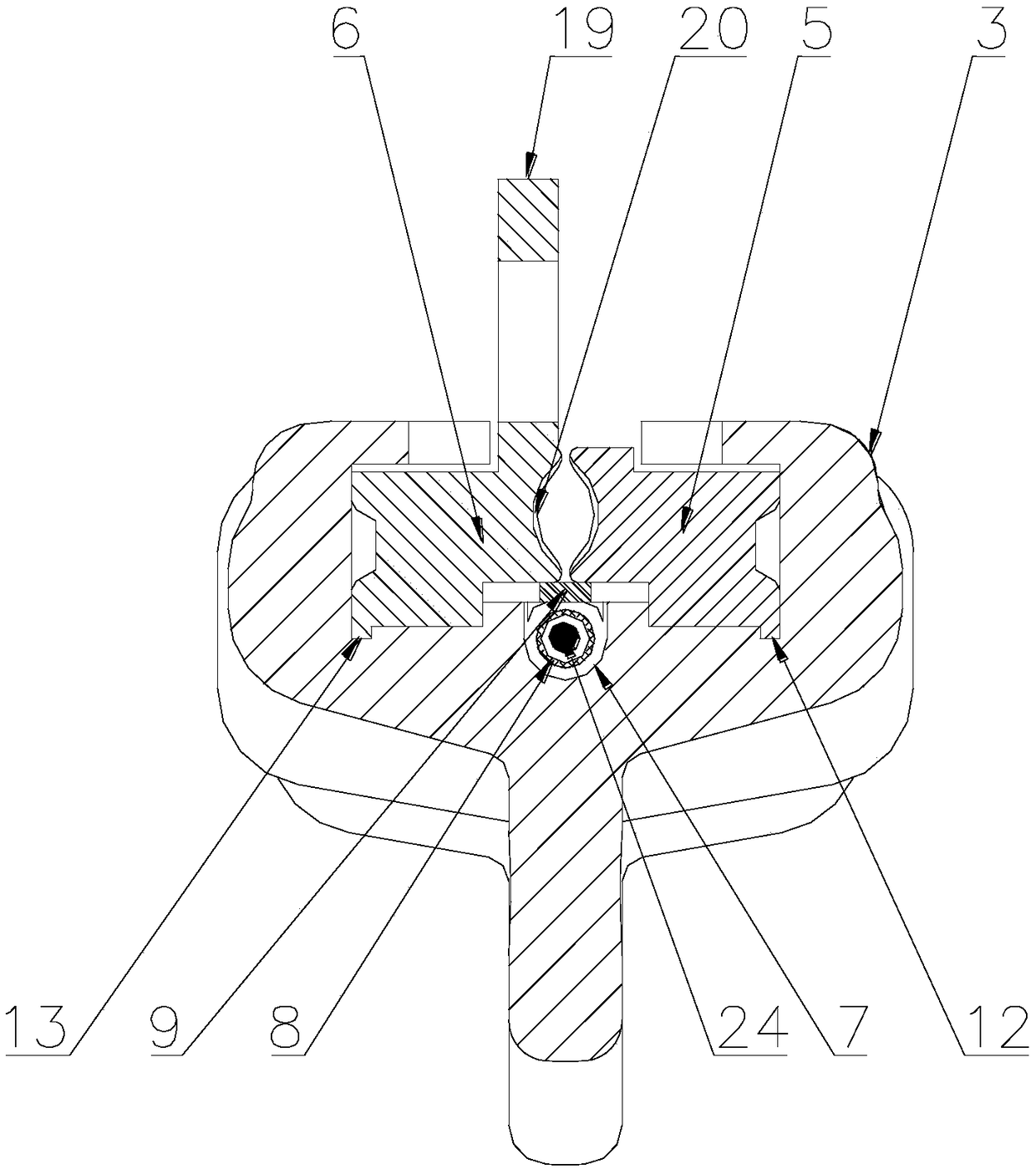

[0049] This embodiment includes a clamp body 3 provided with a latch 1, a connecting rod 2, and a mounting hole 26. The clamp body 3 is provided with wedge-shaped slots with openings at both ends and flash edges on the sides of the slots. Structures are arranged in the wedge-shaped slots. Relatively symmetrical wire clamp I5 and wire clamp II6 that move along the side of the wedge-shaped groove and are wedge-shaped when they are combined; there is a spring movement groove 7 with an arc-shaped cross-section in the middle of the bottom of the wedge-shaped groove. A compression spring 8 is arranged in the movement groove 7, and above the compression spring 8, a spring is laid on the bottom of the wedge-shaped groove to pull the displacement of the compression spring 8 and follow the wire clip I5 and the wire clip. II6 moves and moves the force transmission plate 9 . Instructions attached Figure 15 It is a schematic diagram of the structure of the present invention in a natural ...

Embodiment 2

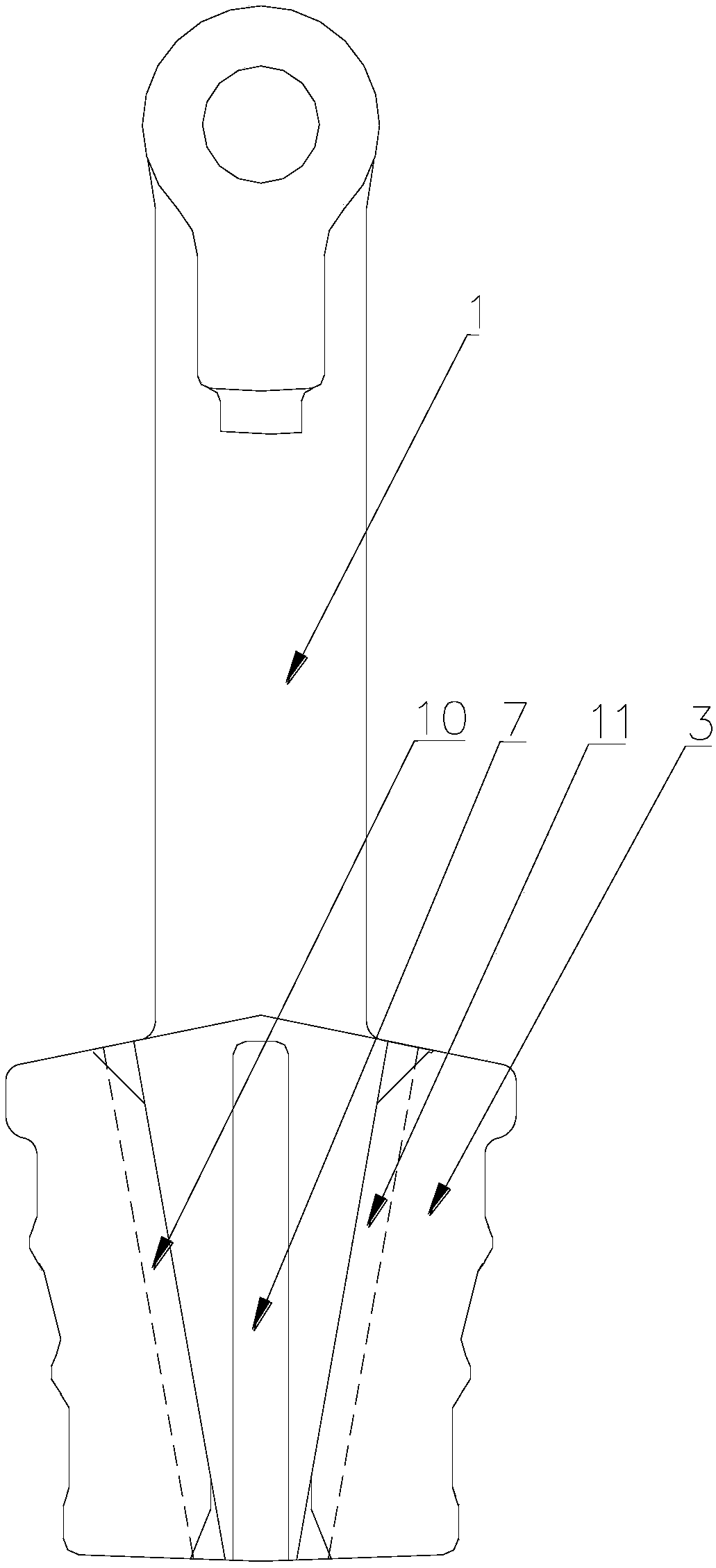

[0052] As attached in the manual Figure 1-13 As shown, the present embodiment is provided with the clamp body 3 of the bolt 1, the connecting rod 2 and the mounting hole 26. The clamp body 3 is provided with wedge-shaped grooves with openings at both ends and flash edges on the sides of the two grooves. There are wire clip I5 and wire clip II6 with symmetrical structure, moving along the side of the wedge-shaped groove, and the two are wedge-shaped when they are combined; there is a spring movement groove 7 with an arc-shaped cross-section in the middle of the bottom of the wedge-shaped groove , the spring movement groove 7 is provided with a compression spring 8, above the compression spring 8 is laid on the bottom of the wedge-shaped groove, pulling the displacement of the compression spring 8, and following the clamp I5 and the The active force transmission plate 9 that moves when the line clamp II 6 moves.

[0053] In this embodiment, groove track I10 and groove track II...

Embodiment 3

[0060] As attached in the manual Figure 1-13 As shown, the present embodiment is provided with the clamp body 3 of the bolt 1, the connecting rod 2 and the mounting hole 26. The clamp body 3 is provided with wedge-shaped grooves with openings at both ends and flash edges on the sides of the two grooves. There are wire clip I5 and wire clip II6 with symmetrical structure, moving along the side of the wedge-shaped groove, and the two are wedge-shaped when they are combined; there is a spring movement groove 7 with an arc-shaped cross-section in the middle of the bottom of the wedge-shaped groove , the spring movement groove 7 is provided with a compression spring 8, above the compression spring 8 is laid on the bottom of the wedge-shaped groove, pulling the displacement of the compression spring 8, and following the clamp I5 and the The active force transmission plate 9 that moves when the line clamp II 6 moves.

[0061] In this embodiment, groove track I10 and groove track II...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com