High-efficiency mailbox device

A high-efficiency, letter-box technology, applied in the field of letter boxes, can solve the problems of waste of raw materials for anti-corrosion coatings, low application efficiency of anti-corrosion coatings, and difficulty in applying operation on the bottom surface of letter boxes, and achieves the effects of convenient operation, reduced manual workload, and improved application quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

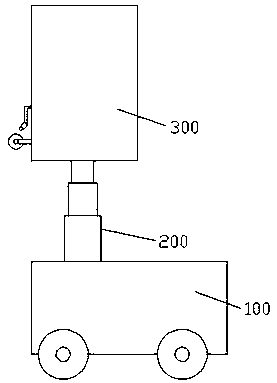

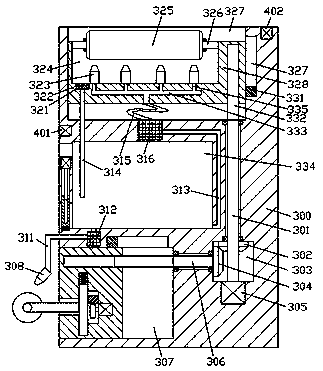

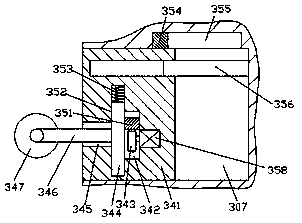

[0016] Combine below Figure 1-4 The present invention will be described in detail.

[0017] refer to Figure 1-4 , according to an embodiment of the present invention, a high-efficiency letter box device includes a traveling vehicle frame 100, a lifting power device 200 installed on the walking vehicle frame 100, and a lifting power device 200 fixedly installed on the lifting power device 200 The smear frame 300 is provided with a first sliding cavity 307 in the left end surface of the smearing frame 300, and a first sliding seat 341 is installed in the first sliding cavity 307, and a first sliding seat 341 is installed in the first sliding seat 341. There is a letter box side smearing member, and the smearing frame 300 on the right side of the first sliding chamber 307 is provided with a transfer chamber 303, and the part between the transfer chamber 303 and the first sliding chamber 307 is rotatably installed with The first transfer shaft 306, the left end of the first tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com