Water squeezing module used for horizontal plate mop, and horizontal plate mop bucket provided with water squeezing module

A flat mop and water mold technology, which is applied to household appliances, applications, floor cleaning, etc., can solve the problems of troublesome use, low economy, and occupying space when idle, and achieves convenient use, enhanced squeezing effect, and installation-free. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

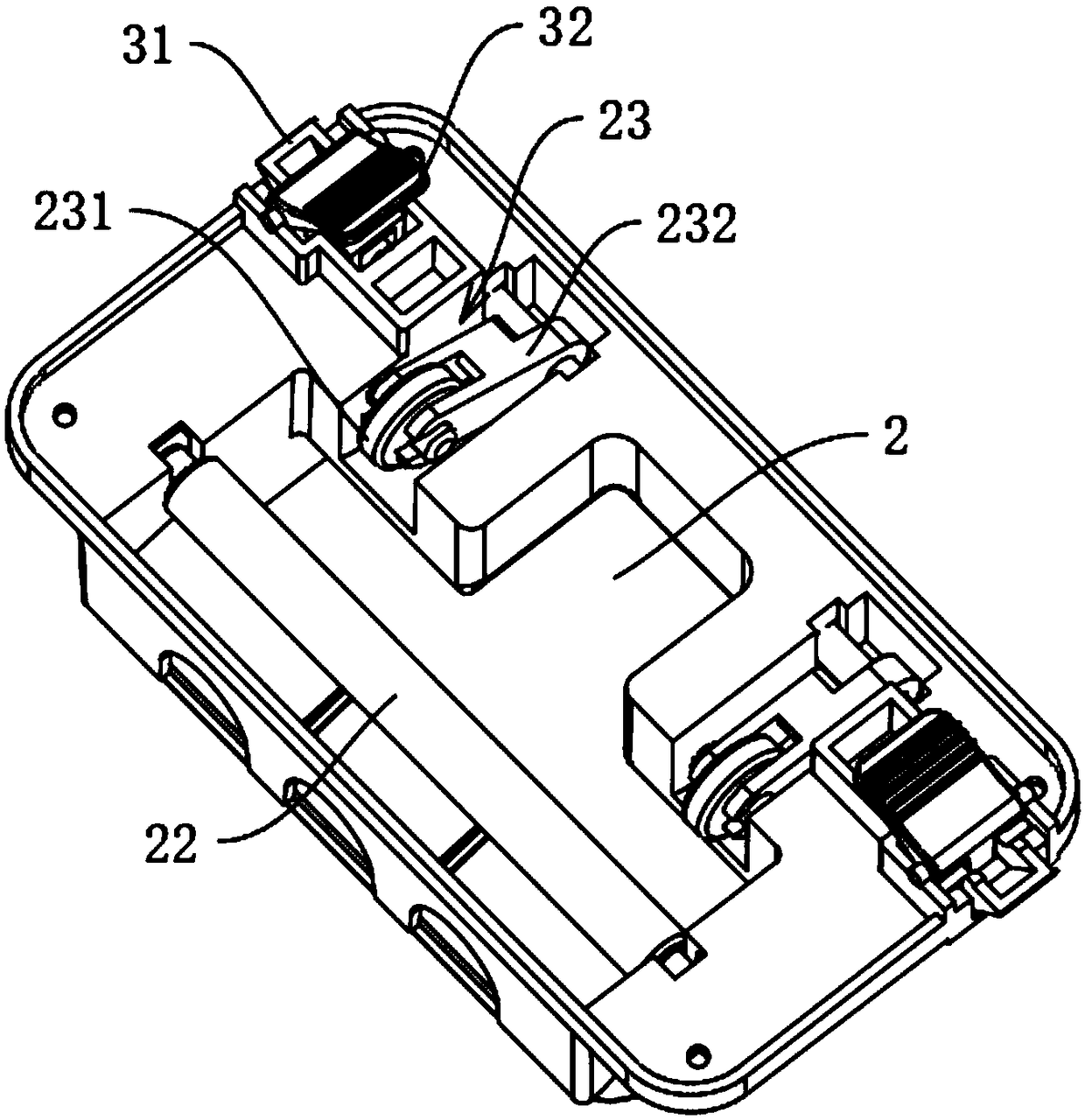

[0053] Example: a water squeezing module for a flat mop, such as figure 1 Shown: the water squeezing module is provided with a quick release mechanism 3, the water squeezing module is detachably installed on the barrel body through the quick release mechanism, and the water squeezing module includes a squeezing port for the flat mop to pass through 2. The water squeezing port is provided with a squeezing member 22 located on the side of the wiper of the flat mop and capable of squeezing the wiper.

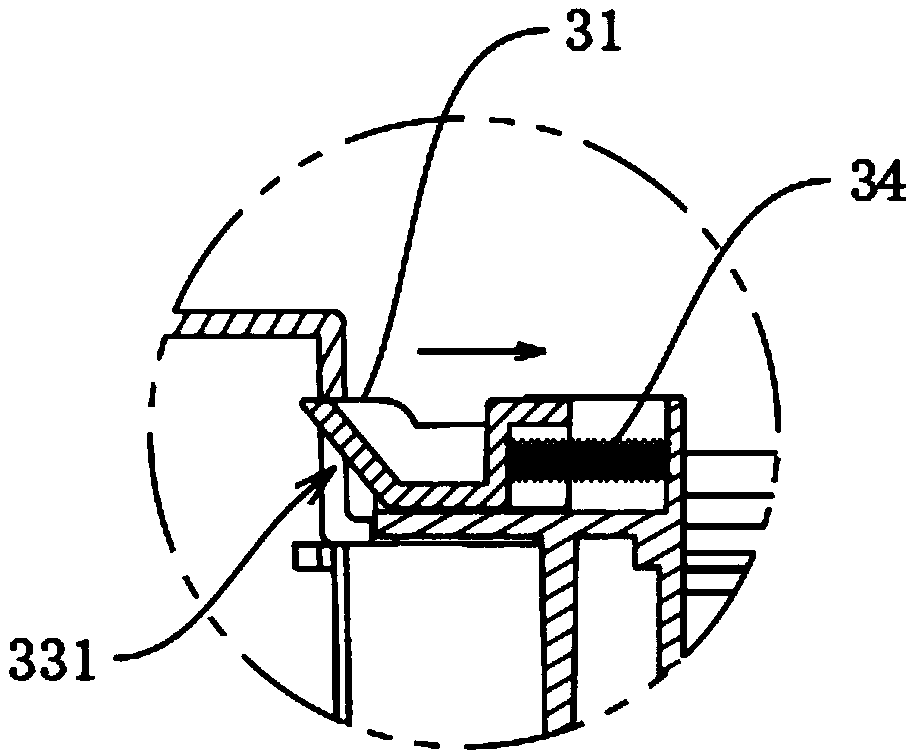

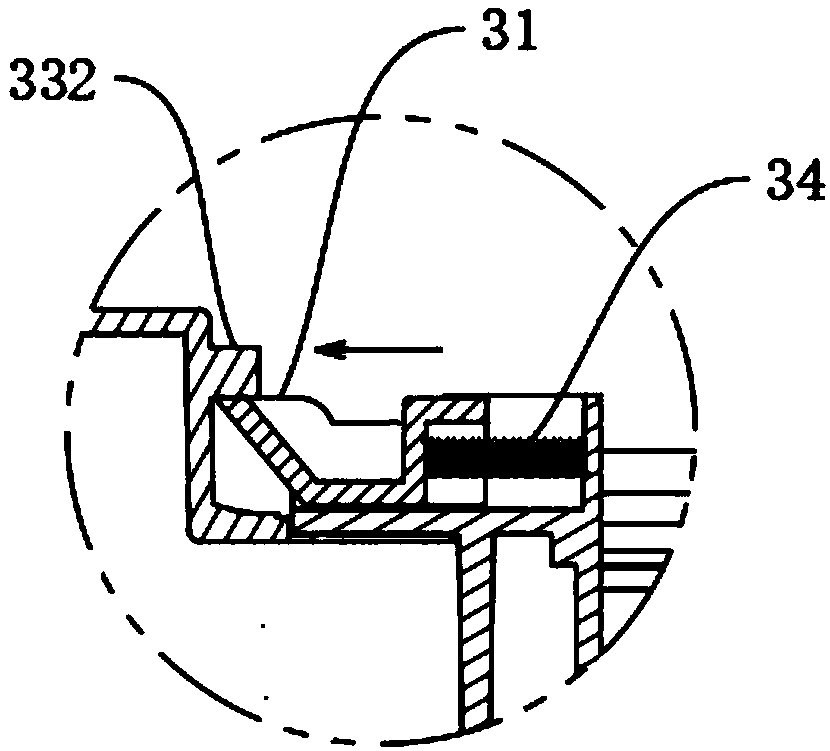

[0054] like figure 1 , figure 2 and image 3 Shown: the quick release mechanism includes an insert block 31, the insert block is located at the edge of the water squeezing module, and the insert block can slide along the plane of the water squeezing module, and the barrel itself is provided with There is a positioning portion 33 or a positioning portion is installed on the barrel body, the insert block can be inserted into and pulled out from the positioning portion, and the po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com