Grinding machine for automobile glass

An automotive glass and grinding machine technology, which is applied to machine tools suitable for grinding workpiece planes, machine tools suitable for grinding workpiece edges, grinding racks, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

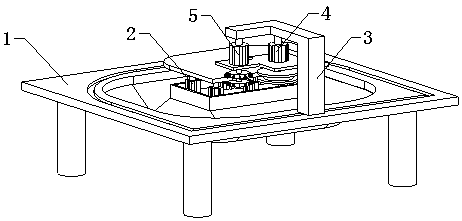

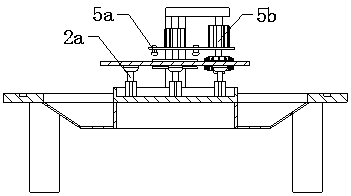

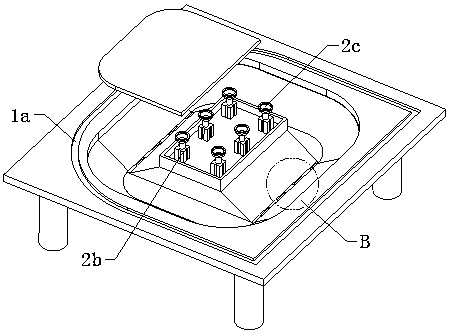

[0022] refer to Figure 1 to Figure 6 A grinding machine for automobile glass shown includes a workbench 1, a workpiece fixing assembly 2 arranged on the top of the workbench 1, a sliding assembly 3 arranged on the top of the workbench 1 and slidably connected with the workbench 1, arranged on the The glass grinding assembly 4 and the glass cleaning assembly 5 on the sliding assembly 3, the workpiece fixing assembly 2 includes several workpiece holders 2a, each of the workpiece holders 2a is fixedly arranged on the top of the workbench 1, and the glass grinding The assembly 4 includes a first motor 4a, an upper grinding disc 4b for grinding the upper surface of the glass, an edge grinding disc 4c for grinding the edge of the glass and a lower grinding disc 4d for grinding the lower surface of the glass, and the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com