Classification type fully-automatic bagging garbage can

A garbage can, fully automatic technology, applied in the field of garbage cans, can solve the problem of inability to realize garbage recycling and other problems, and achieve the effect of simple production and easy replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The content of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments of the description:

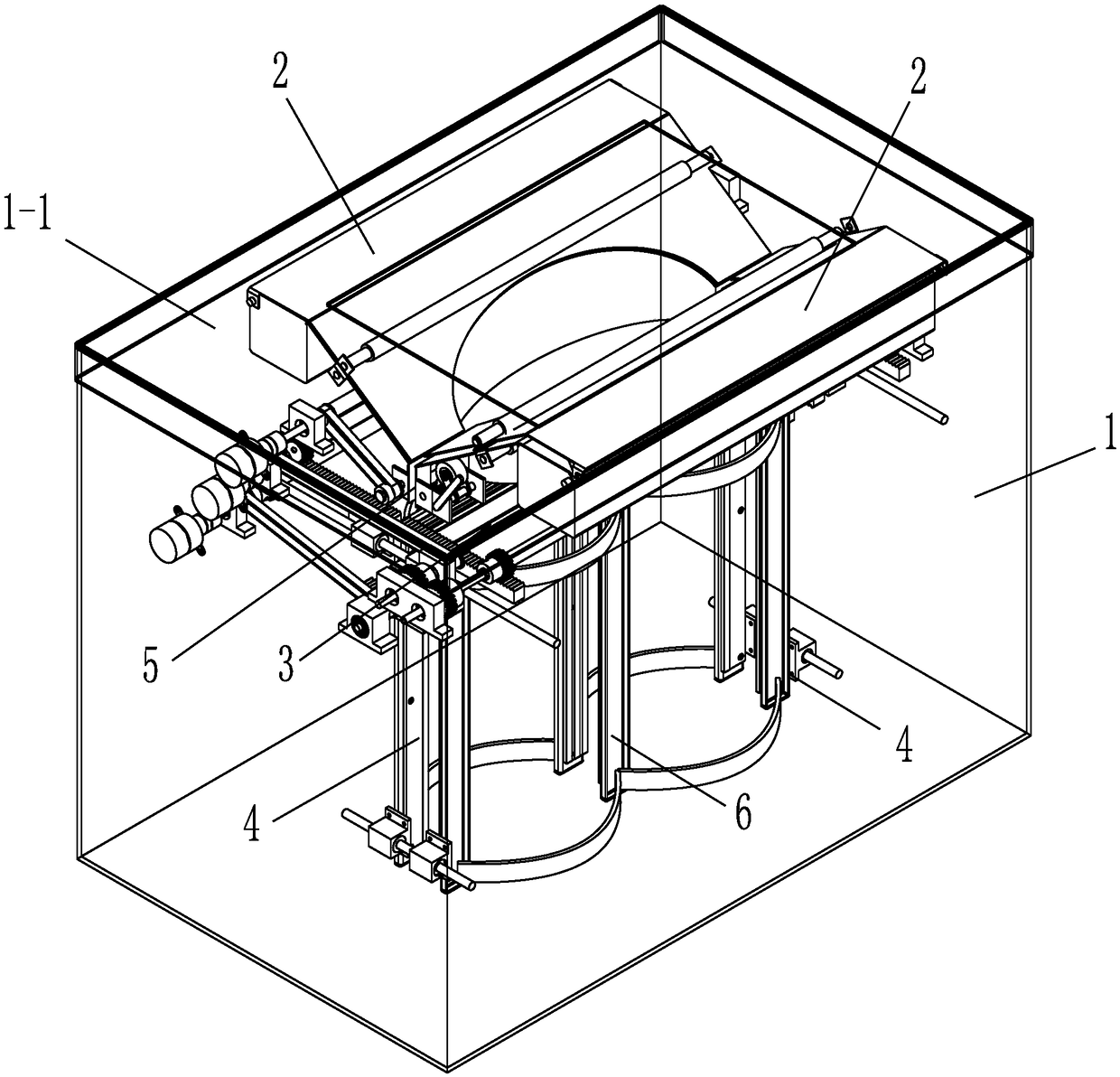

[0020] Such as Figures 1 to 7 Shown is a schematic diagram of an embodiment of a classified fully automatic bagging trash can provided by the present invention.

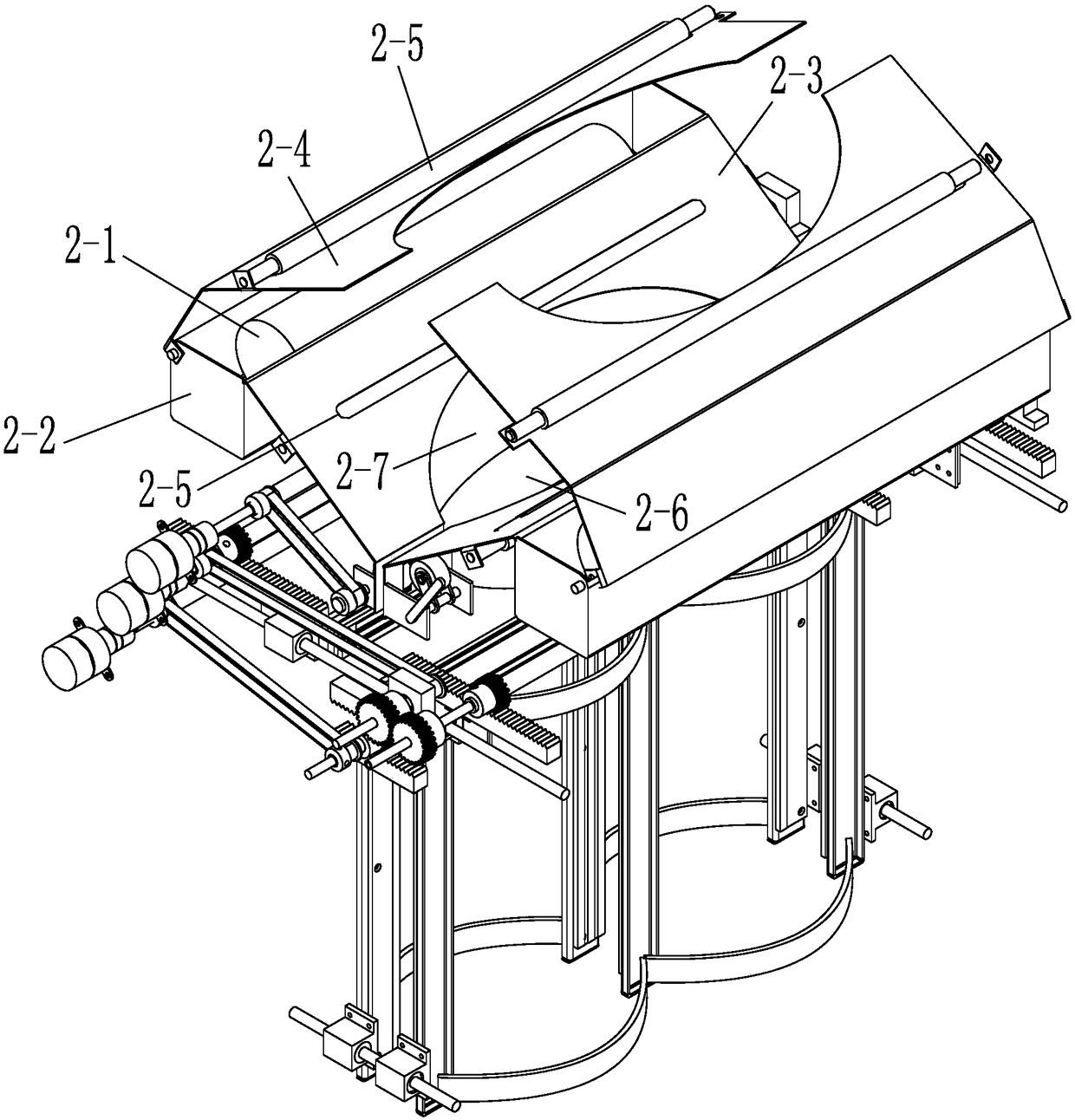

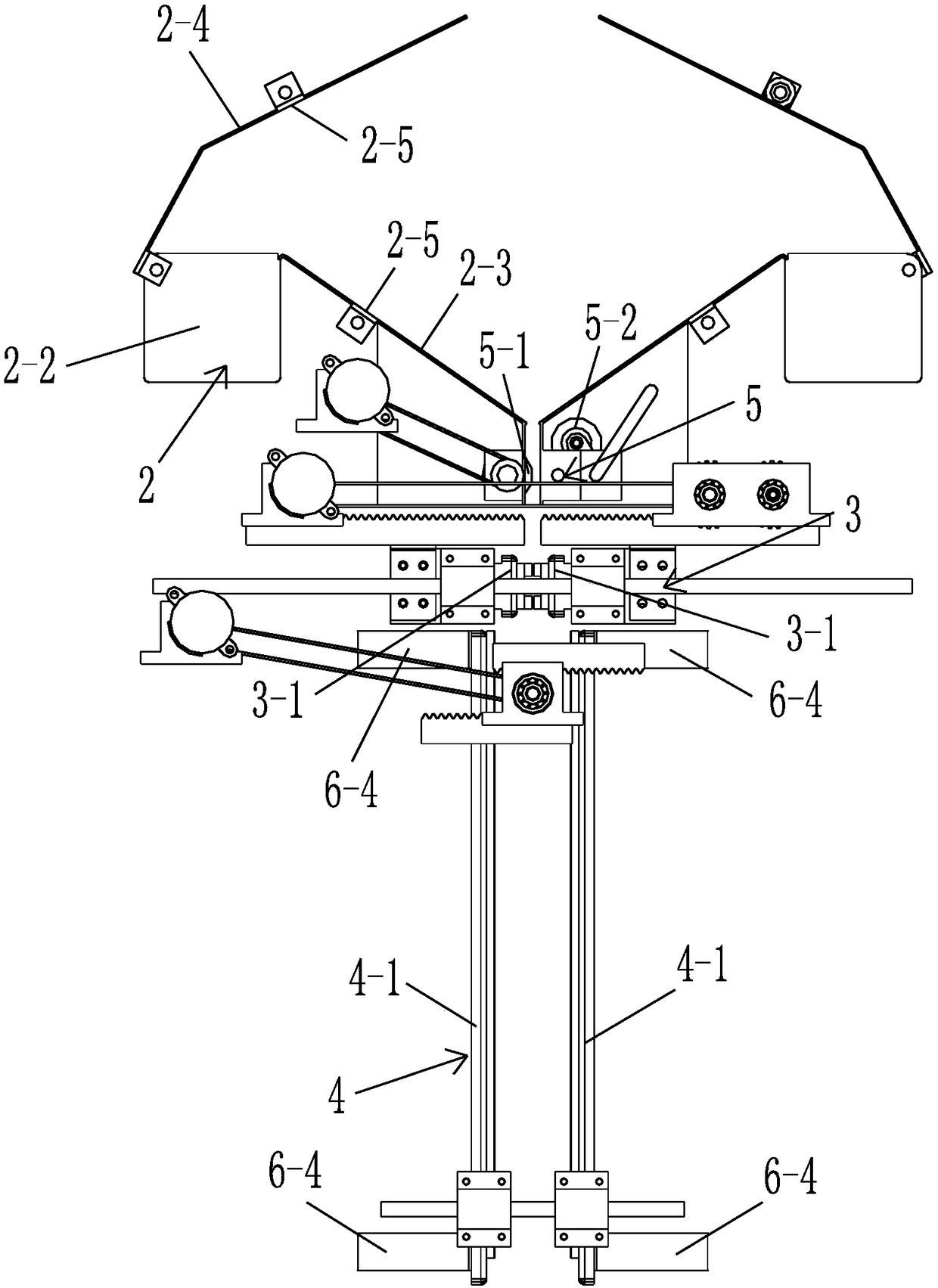

[0021] A sorted fully automatic bagging trash can, which includes a barrel body 1, two bag discharge devices 2 arranged on the left and right sides of the upper part of the barrel body 1, and a bottom sealing and trimming device 3 arranged on the lower side of the bag discharge device 2, and a side sealing edge Device 4, bag-dividing device 6;

[0022] The bag-out device 2 includes a garbage bag roller 2-1 extending forward and backward, and the garbage bag roller 2-1 is made of a single-layer film; A bag feeding device 5 that forms a double-layer film and conveys it downward;

[0023] The bottom sealing edge trimming device 3 includes two transverse pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com