Composite cement grinding aid

A cement grinding aid and composite technology, applied in the field of cement manufacturing, can solve problems such as inability to mix cement raw materials and effective grinding aid ingredients together, failure to achieve the best effect of cement grinding aid, chloride ion or alkali hazards, etc. Achieve the effect of stable raw material source, simple manufacturing, and improved distribution and shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

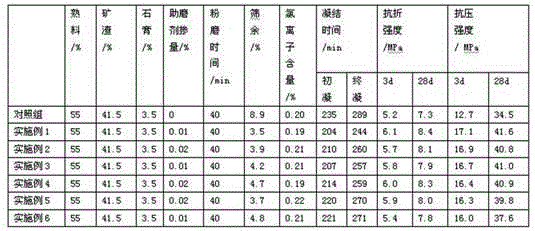

Embodiment 1

[0023] Add 5 kg of sodium metasilicate pentahydrate into 28 kg of water and stir until completely dissolved, heat to a temperature of 25°C, then add 4.5 kg of sodium hexametaphosphate to the solution of sodium metasilicate pentahydrate, and continue heating to a temperature of 45°C , stirring and dissolving, finally adding 18 kg of polyol amines, 9 kg of polyols, and 12 kg of molasses into the solution and stirring until completely dissolved, then cooling and filtering. Among them, the polyol amine is composed of 10.8 kg of triethanolamine and 7.2 kg of triisopropanolamine, and the polyol is composed of 2.57 kg of glycerol, 2.57 kg of trimethylolethane, and 3.86 kg of pentaerythritol.

Embodiment 2

[0025] Add 8 kg of sodium metasilicate pentahydrate to 40 kg of water and stir until completely dissolved, heat to a temperature of 25°C, then add 4 kg of sodium hexametaphosphate to the solution of sodium metasilicate pentahydrate, and continue heating to a temperature of 45°C , stirring and dissolving, finally adding 5 kg of polyol amines, 15 kg of polyols, and 5 kg of molasses into the solution and stirring until completely dissolved, then cooling and filtering. Wherein, the polyol amine is composed of 2.5 kg of triethanolamine and 2.5 kg of triisopropanolamine, and the polyol is composed of 2.5 kg of glycerol, 5 kg of trimethylolethane, and 7.5 kg of pentaerythritol.

Embodiment 3

[0027] Add 4 kg of sodium metasilicate pentahydrate into 25 kg of water and stir until completely dissolved, heat to a temperature of 25°C, then add 6 kg of sodium hexametaphosphate to the solution of sodium metasilicate pentahydrate, and continue heating to a temperature of 45°C , stirring and dissolving, finally adding 35 kilograms of polyol amines, 3 kilograms of polyols, and 15 kilograms of molasses into the solution and stirring until completely dissolved, then cooling and filtering. Among them, the polyol amine is composed of 23.3 kg of triethanolamine and 11.7 kg of triisopropanolamine, and the polyol is composed of 1.125 kg of glycerol, 0.75 kg of trimethylolethane, and 1.125 kg of pentaerythritol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com