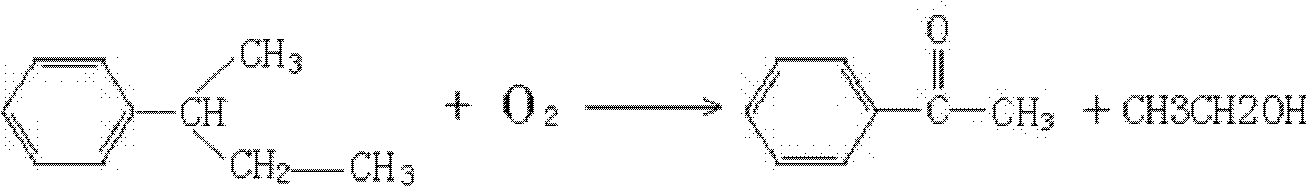

Method for preparing acetophenone

A technology of acetophenone and sec-butylbenzene, which is applied in the field of preparation of acetophenone, can solve problems such as the preparation of acetophenone, and achieve the effects of stable source of raw materials, easy operation and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Add 259 grams of sec-butylbenzene with a purity of 98.67% into an autoclave with a volume of 500 ml, then add 0.5 grams of NaOH and 2 ml of water, seal it, and heat the mixture to 130 ° C at a mechanical stirring speed of 700 rpm, and adjust the pressure adjustment The valve keeps the pressure in the kettle at 0.2M Pa. After 6 hours of reaction, a sample is taken for GC analysis. The conversion rate of sec-butylbenzene is 17.8%, and the selectivity of acetophenone is 15.2%.

Embodiment 2

[0024] Add 259 grams of sec-butylbenzene with a purity of 98.67% into an autoclave with a volume of 500 ml, then add 0.5 grams of Na2CO3 and 2 ml of water, seal it, and heat the mixture to 130 ° C at a mechanical stirring speed of 700 rpm, and adjust the pressure adjustment The valve keeps the pressure in the kettle at 1.2 MPa. After 9 hours of reaction, a sample is taken for GC analysis. The conversion rate of sec-butylbenzene is 27.6%, and the selectivity of acetophenone is 14.3%.

Embodiment 3

[0026] Add 259 grams of sec-butylbenzene with a purity of 98.67% into an autoclave with a volume of 500 ml, then add 0.5 grams of Na2CO3 and 2 ml of water, seal it, and heat the mixture to 180 ° C at a mechanical stirring speed of 700 rpm, adjust the pressure adjustment The valve keeps the pressure in the kettle at 1.2 MPa. After 9 hours of reaction, a sample is taken for GC analysis. The conversion rate of sec-butylbenzene is 76.1%, and the selectivity of acetophenone is 67.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com