Mixed concrete

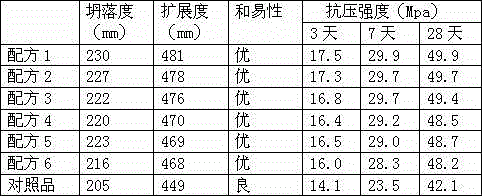

A technology for concrete and setting retarder, applied in the field of concrete, can solve the problems of low concrete fluidity, large concrete slump, poor corrosion resistance, etc., and achieve the effects of enhancing corrosion resistance, improving later strength, and reducing sensitivity

Inactive Publication Date: 2015-10-14

湖州华仑助剂科技有限公司

View PDF7 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The existing concrete usually has the following problems in the process of use: 1. The concrete has low fluidity, a large amount of cement, and a large amount of water; 2. The concrete added with a reinforcing agent is affect

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a mixed concrete, which is characterized by being composed of the following components in parts by weight: 300 to 500 parts of cement, 200 to 300 parts of yellow sand, 150 to 350 parts of fine aggregate sand, 150 to 350 parts of coarse aggregate sand, 5 to 10 parts of reinforcing agent, and 100 to 200 parts of water. The raw material resource is stable, the raw materials are environment-friendly and have little toxicity, and the production and manufacture are simple. A better synergetic effect can be achieved by determining the components and the component content ranges. Gas-phase titanium dioxide and gas-phase alumina are co-used with sodium metasilicate pentahydrate to effectively reduce the sensitivity to silt content; volcanic ash is co-used with alumina to effectively enhance the anti-corrosion performance of concrete; isopropanol and triethanolamine are used together to improve the work performance and state of concrete and increase the concrete later strength.

Description

technical field [0001] The invention belongs to the technical field of concrete, and in particular relates to a mixed concrete. Background technique [0002] Concrete, referred to as concrete for short, refers to the collective name of engineering composite materials in which aggregates are cemented into a whole by cementitious materials. Generally speaking, concrete refers to the cement concrete obtained by using cement as the cementitious material, sand and stone as the aggregate; mixed with water (may contain admixtures and admixtures) in a certain proportion, and stirred, also known as ordinary concrete. It is widely used in civil engineering. [0003] Concrete is one of the most important contemporary civil engineering materials. It is prepared in a certain proportion by cementitious materials, granular aggregates (also known as aggregates), water, and admixtures and admixtures added when necessary. It is a kind of artificial stone that is uniformly stirred, densely f...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C04B28/00C04B14/06

Inventor 李琪

Owner 湖州华仑助剂科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com