PET film pasted type transparent anti-ultraviolet screen and production method thereof

A technology of anti-ultraviolet and production methods, applied in the direction of chemical instruments and methods, layered products, synthetic resin layered products, etc., can solve problems such as insufficient contrast and image depth of field, inconvenient wearing glasses, and lack of signal color, etc. Achieve high production efficiency, remarkable transparent imaging effect, simple production and manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

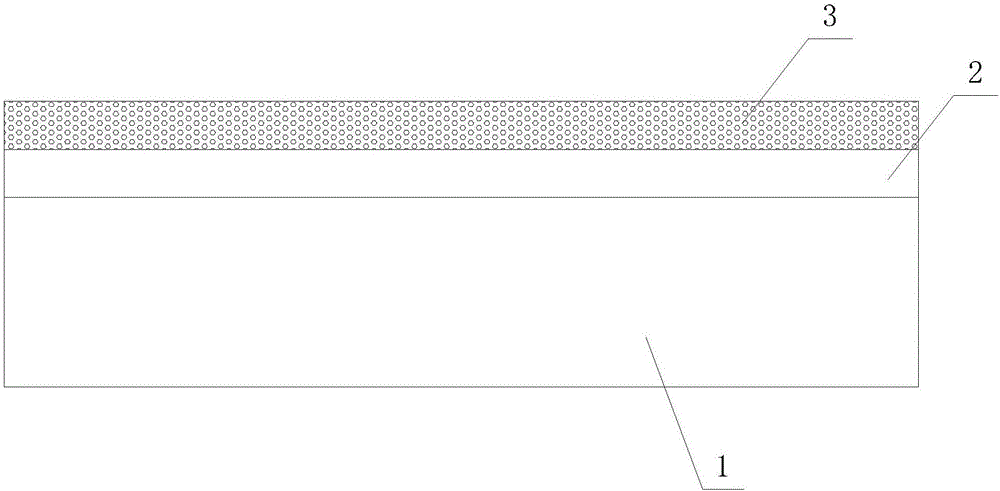

[0053] Such as figure 1 As shown, a PET film-type transparent anti-ultraviolet projection screen, which includes a PET film layer 3, an adhesive layer 2, and a transparent support layer 1 that are stacked sequentially from top to bottom, and the transparent support layer 1 is transparent polycarbonate board, with a thickness of 0.1 mm, and the adhesive layer 2 is uniformly coated with ethyl acrylate, rosin resin and ethylene glycol at a mass ratio of 2.5:1:2.5 after stirring at 50°C;

[0054] The PET film layer 3 is made of PET resin, antioxidant, light stabilizer and nano particle dispersion in a molten state, mixed uniformly, pre-crystallized and dried, and then extruded and stretched. The nano particle dispersion is composed of nanoparticles , dispersant and solvent are uniformly mixed and then dispersed by ultrasonic waves, the nanoparticles are composed of titanium dioxide nanoparticles and inorganic salt nanoparticles with a mass ratio of 1:9, wherein the titanium dioxid...

Embodiment 2

[0064] Such as figure 1 As shown, a PET film-type transparent anti-ultraviolet projection screen, which includes a PET film layer 3, an adhesive layer 2, and a transparent support layer 1 that are sequentially stacked from top to bottom, and the transparent support layer 1 is a transparent glass plate. The thickness is 20 mm, and the adhesive layer 2 is formed by uniform coating of ethyl acrylate, rosin resin and ethylene glycol with a mass ratio of 3.5:1:3.5 at 60° C.;

[0065] The PET film layer 3 is made of PET resin, antioxidant, light stabilizer and nano particle dispersion in a molten state, mixed uniformly, pre-crystallized and dried, and then extruded and stretched. The nano particle dispersion is composed of nanoparticles , dispersant and solvent are uniformly mixed and then dispersed by ultrasonic waves, the nanoparticles are composed of titanium dioxide nanoparticles and inorganic salt nanoparticles with a mass ratio of 9:1, wherein the titanium dioxide nanoparticle...

Embodiment 3

[0075] Such as figure 1As shown, a PET film-type transparent anti-ultraviolet projection screen, which includes a PET film layer 3, an adhesive layer 2, and a transparent support layer 1 stacked sequentially from top to bottom, and the transparent support layer 1 is a transparent acrylic hardened plate , with a thickness of 10mm, the adhesive layer 2 is uniformly coated with ethyl acrylate, rosin resin and ethylene glycol with a mass ratio of 3:1:3 at 55° C.;

[0076] The PET film layer 3 is made of PET resin, antioxidant, light stabilizer and nano particle dispersion in a molten state, mixed uniformly, pre-crystallized and dried, and then extruded and stretched. The nano particle dispersion is composed of nanoparticles , dispersant and solvent are uniformly mixed and then dispersed by ultrasonic waves, the nanoparticles are composed of titanium dioxide nanoparticles and inorganic salt nanoparticles with a mass ratio of 1:1, wherein the titanium dioxide nanoparticles have an a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com