Assembled steel structure lift shaft

An elevator shaft and steel structure technology, applied in the elevator industry, can solve the problems of hidden safety hazards affecting the lives of on-site residents, complex process requirements, and high product costs, and achieve faster overall construction time, process requirements are simple and easy to operate, and the installation period is short. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

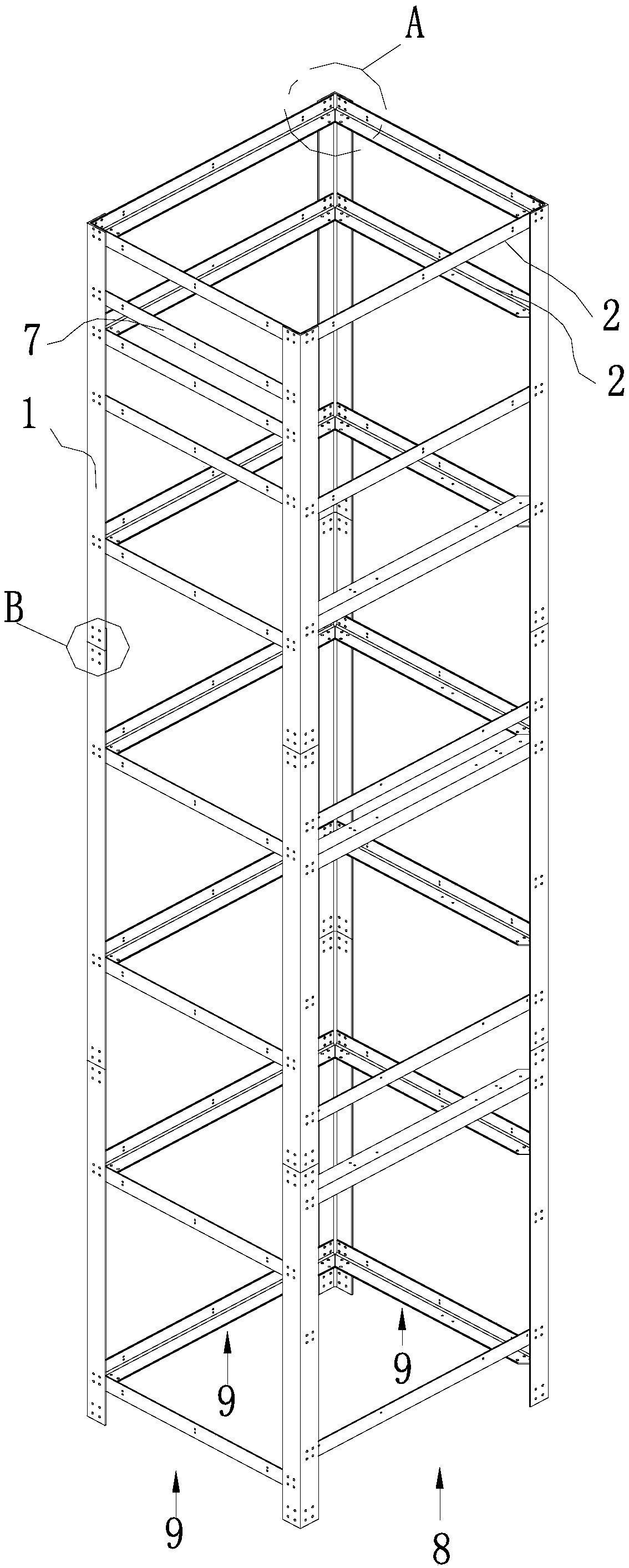

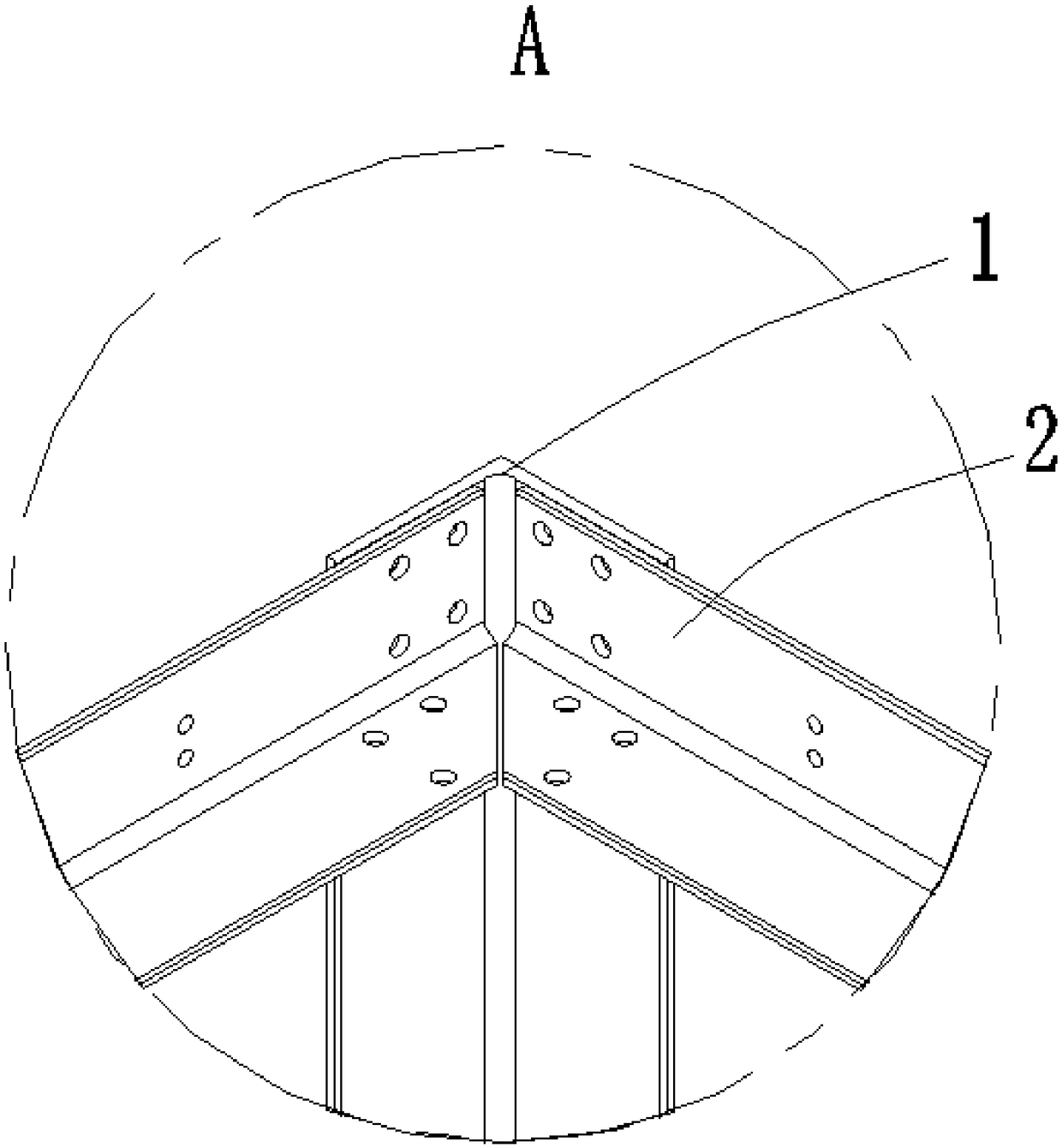

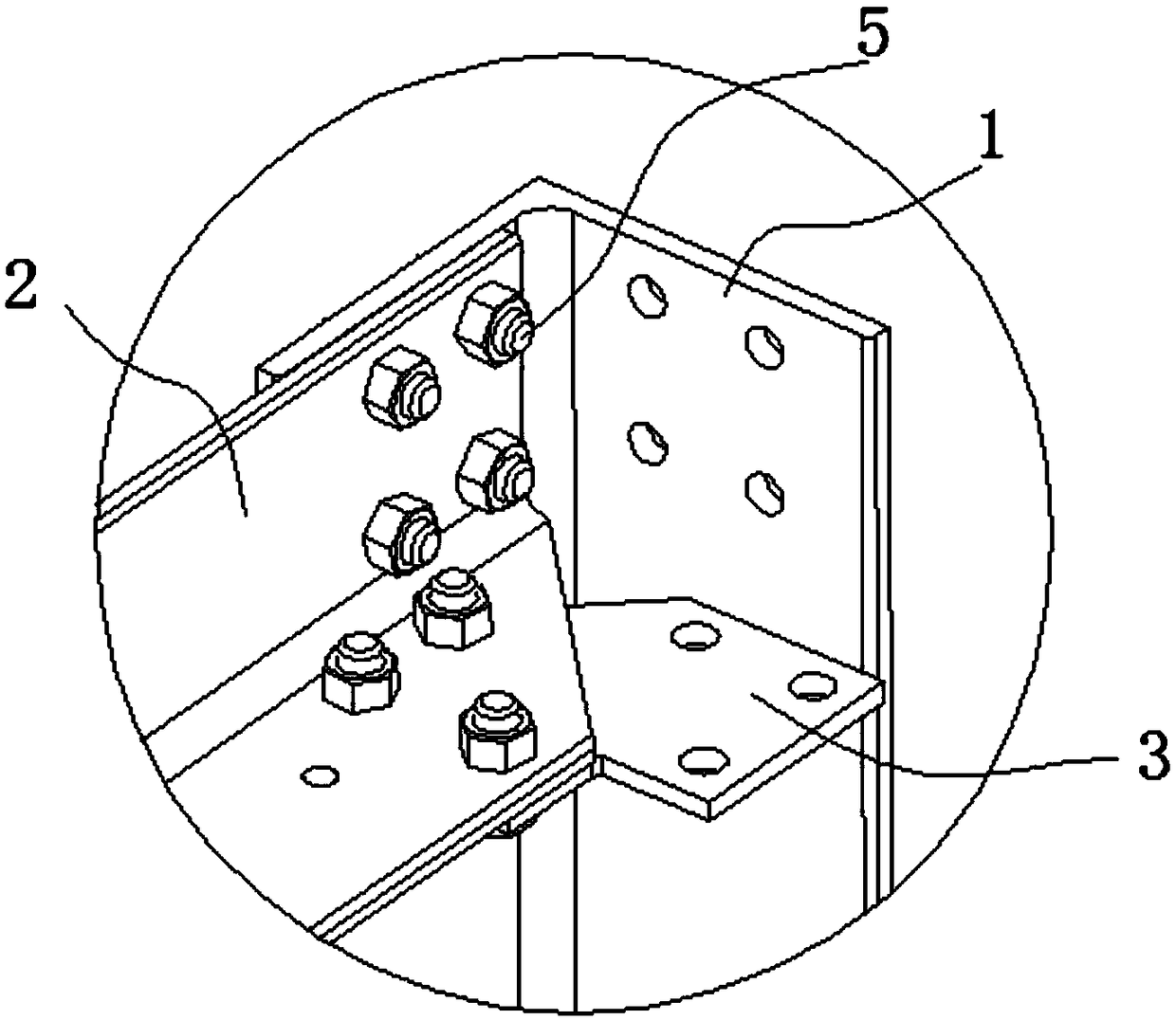

[0021] Such as figure 1 As shown in / 2 / 3 / 4, the assembled steel structure elevator shaft includes a plurality of longitudinal beams arranged in parallel and surrounded to form a rectangular column, and a plurality of crossbeams 2 connected between the longitudinal beams so that the longitudinal beams are connected to form a whole, The height direction of the hoistway is the up-and-down direction, and each longitudinal beam includes a plurality of longitudinal connection units 1, a connection assembly connected between the longitudinal connection units 1 so that two vertical connection units 1 adjacent up and down are fixedly connected, and the cross beam 2 and the longitudinal beam They are perpendicular to each other and connected between two adjacent vertical connection units 1 on the left and right.

[0022] In this embodiment: the connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com