Hoisting tool and method for marine low-speed diesel engine electric vibration compensator

A technology of electric vibration and lifting tools, which is applied in the direction of load hanging components, transportation and packaging, etc., can solve the problems of hidden safety hazards, cumbersome operation process, and long time-consuming, and achieve the effect of overcoming safety impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

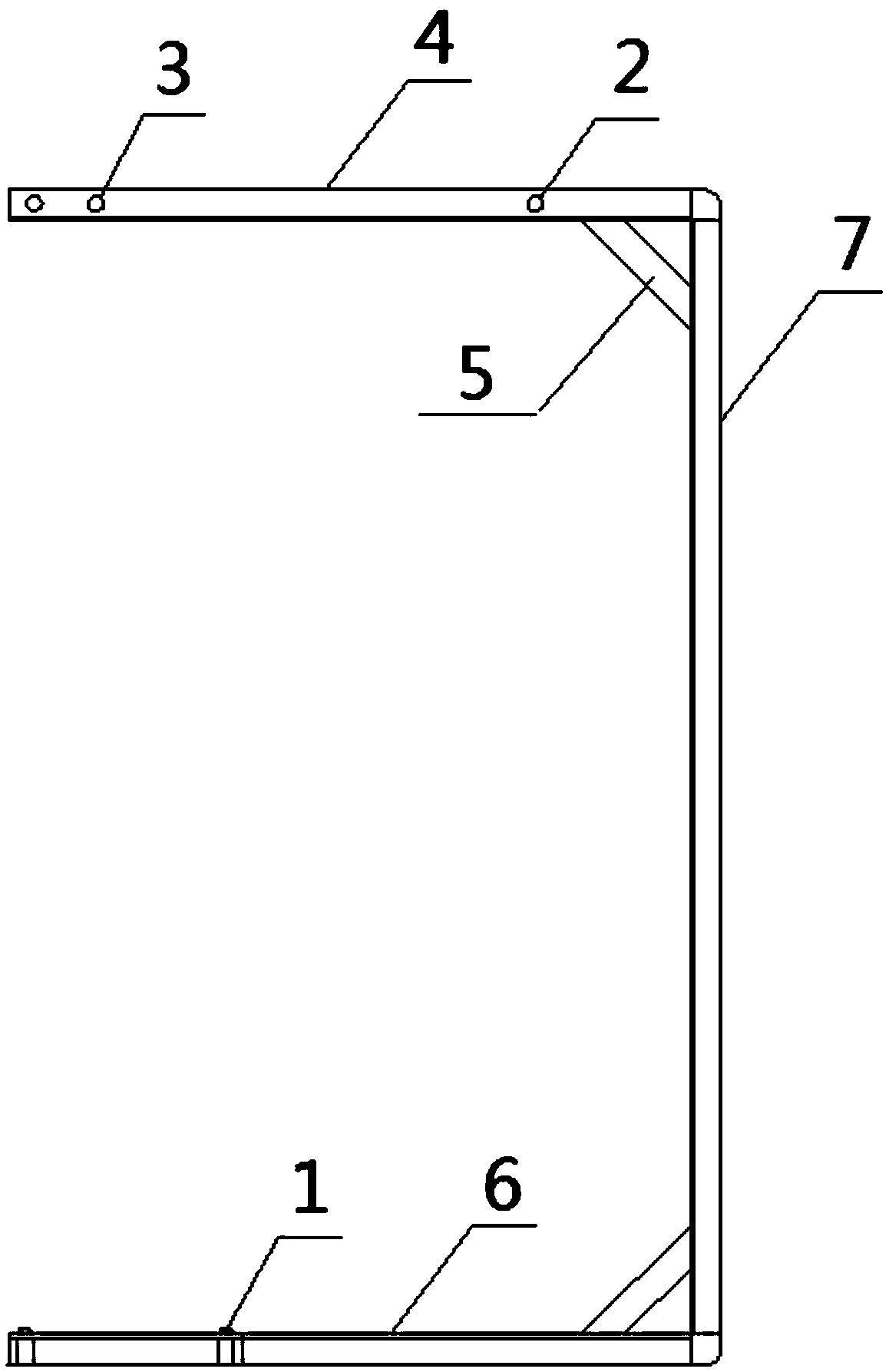

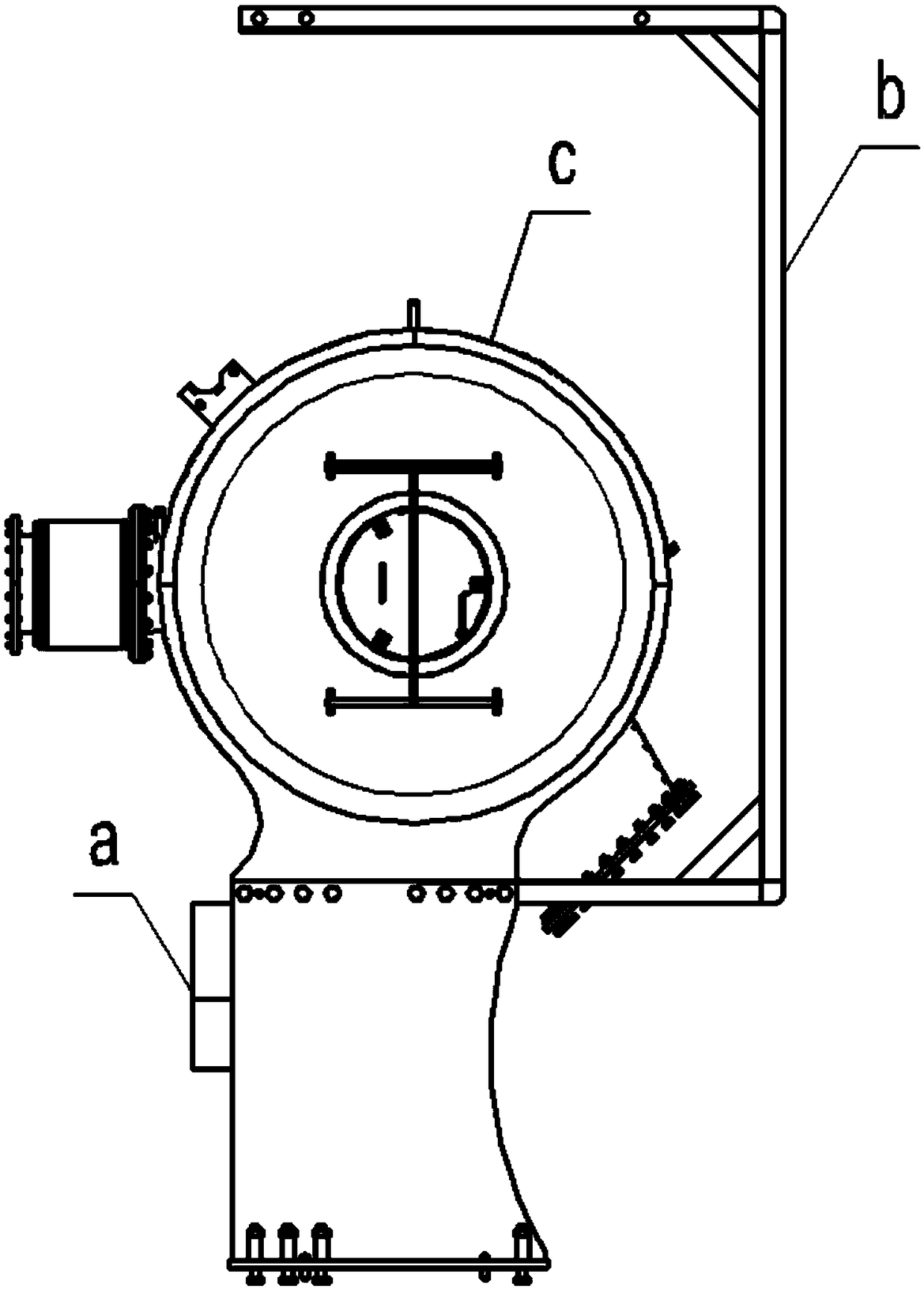

[0026] see figure 1 , the lifting tool b is in the shape of a semi-open door frame and is made of T-shaped steel, which is welded from the end of the upper beam, the column and the lower beam in sequence. Considering the strength during hoisting, a diagonal brace 5 is welded between the upper beam 4 and the upper end of the column 7 , and a diagonal brace 5 is welded between the lower beam 6 and the lower end of the column 7 . The brace 5 is used to strengthen the strength of the lifting tool b. The space surrounded by the upper beam 4, the lower beam 6 and the column 7 is used to accommodate the exhaust manifold c of the marine low-speed diesel engine, see figure 2 The size of this space is determined according to the diameter of the exhaust header c of the model to be installed, which can ensure that the upper beam 4 will not interfere with the exhaust header c after the electric vibration compensator a is hoisted and seated.

[0027] The lower beam 6 is provided with bol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com