Electric high stacking power vehicle capable of being easily controlled

A power car and electric technology, applied in the direction of lifting devices, etc., can solve problems such as undesigned pedals, casualties, and difficulty in steering when stacking high power cars

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

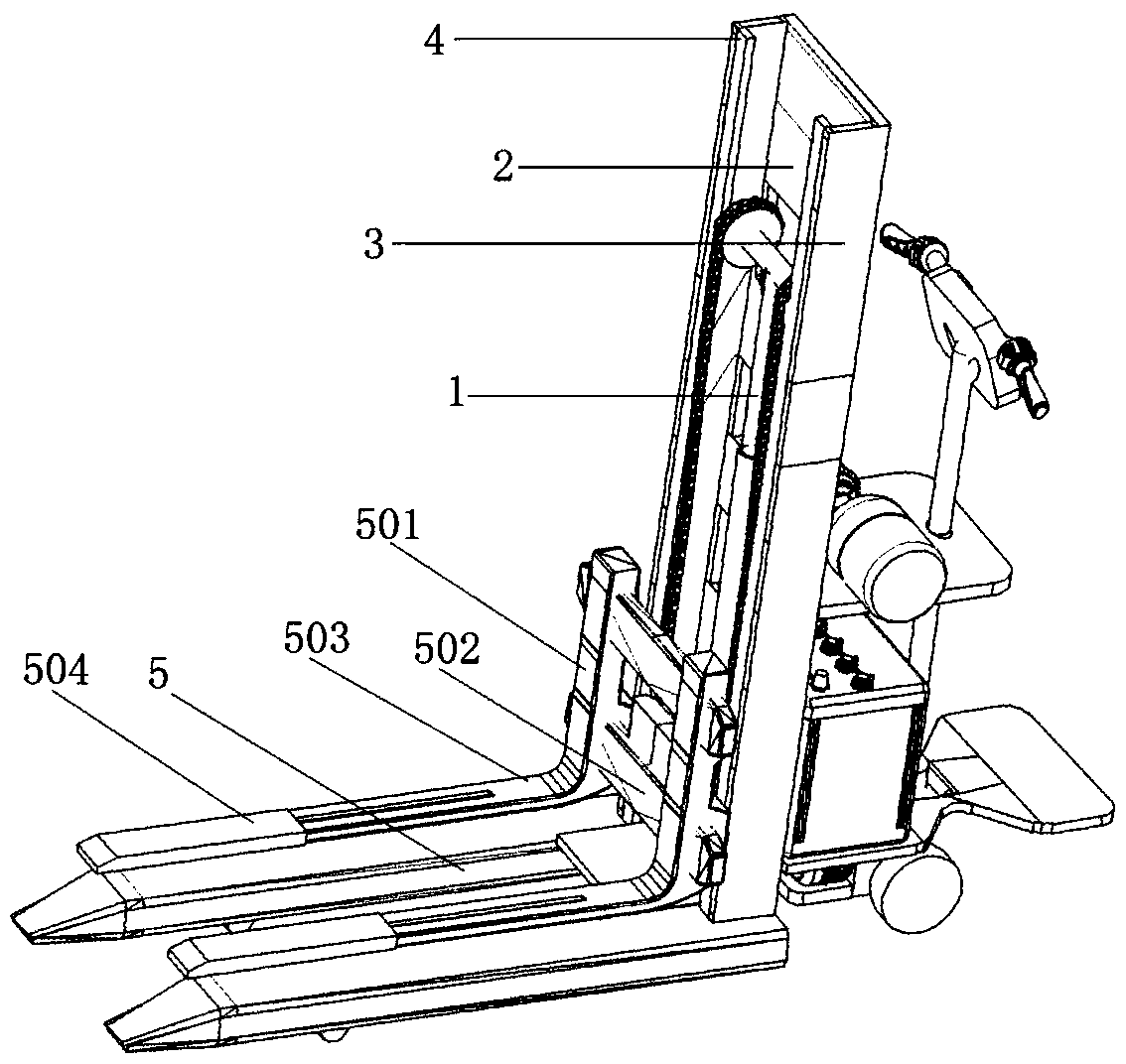

[0099] An electric stacking power vehicle that is easy to control, the electric stacking power vehicle includes a hydraulic lifting device 1, a back plate 2, a side plate 3, a guide rail groove 4, a fork assembly 5, a traveling device 30, a front wheel 31, and a front foot 32; There are two side plates 3, which are fixed on both sides of the back plate 2, and the guide rail groove 4 is fixed on the side plate 3; the front legs 32 are two, arranged in parallel, and connected to the lower ends of the side plates 3 respectively, and the front wheels 31 are connected to the front legs 32 away from the the lower side of one end of the side plate 3;

[0100] The hydraulic lifting device 1 includes a chain connection block 6, a chain 7, a pulley 8, a hydraulic rod outer tube 9, a hydraulic rod inner tube 10, a pulley shaft 34 arranged on the inner side of the guide rail groove 4, and also includes an oil cylinder 11, an oil pipe 12, and a motor 13; The motor 13 is arranged on the oil...

Embodiment 2

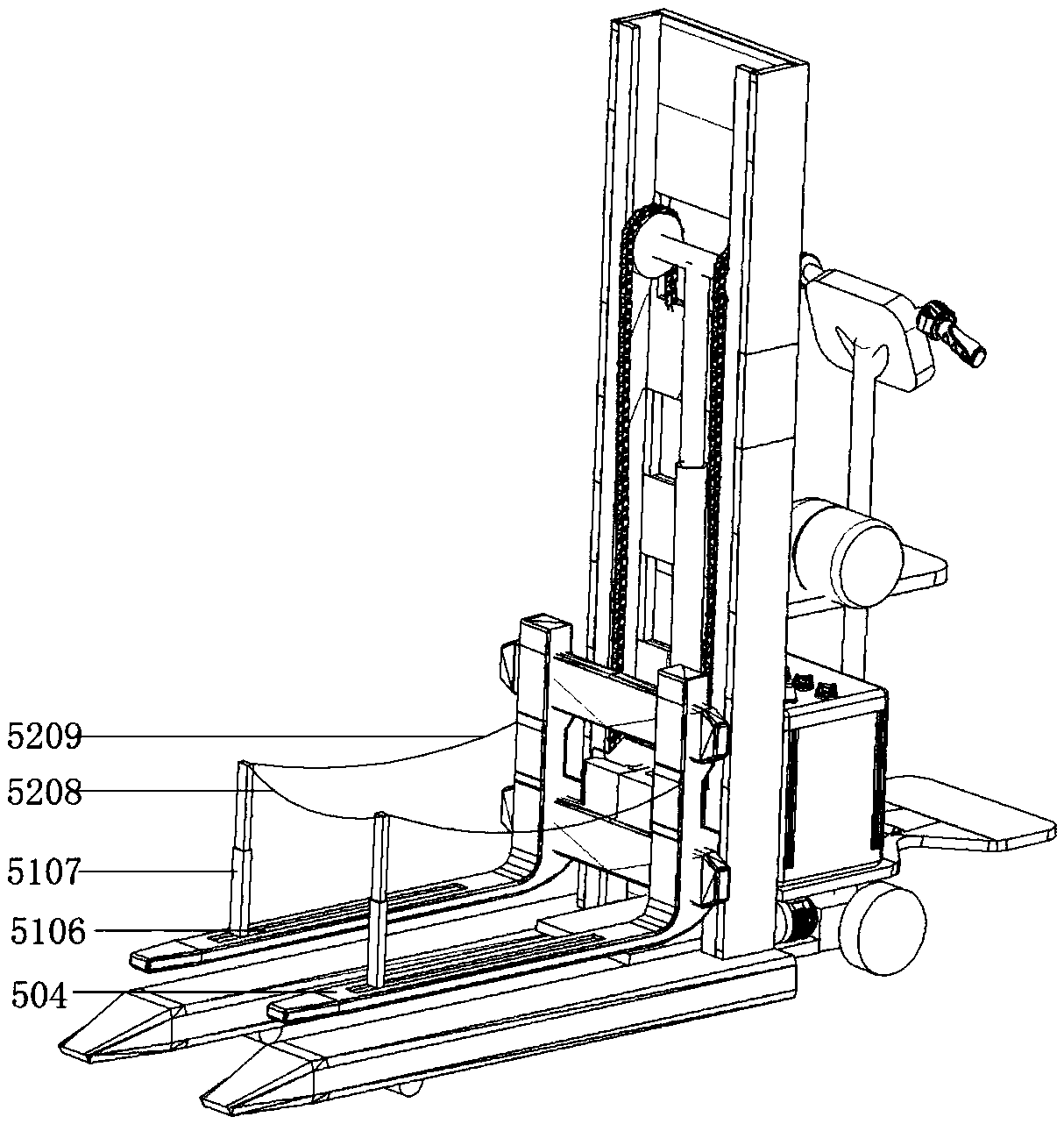

[0116] The fork assembly 5 of the stacker in this embodiment also includes a second power switch 5104, a second controller 5111, a second sliding assembly, a connecting assembly, and a fixed rod group 5107. The second power switch 5104 is arranged outside the bracket 501, extending The arm 504 is an open tubular structure with a fixed rod chute 5106 on the upper part, and the second controller 5111, the second sliding assembly, the connecting assembly, and the fixed rod group 5107 are arranged inside the tubular structure of the extension arm 504;

[0117]The second controller 5111 is arranged at one end of the extension arm 504 close to the beam 502, the second sliding assembly is arranged at the other end of the extension arm 504, the connecting assembly is arranged on the second sliding assembly, and the fixed rod group 5107 is connected with the second sliding assembly through the connecting assembly. The components are hinged, and the fixed rod group 5107 can be turned inw...

Embodiment 3

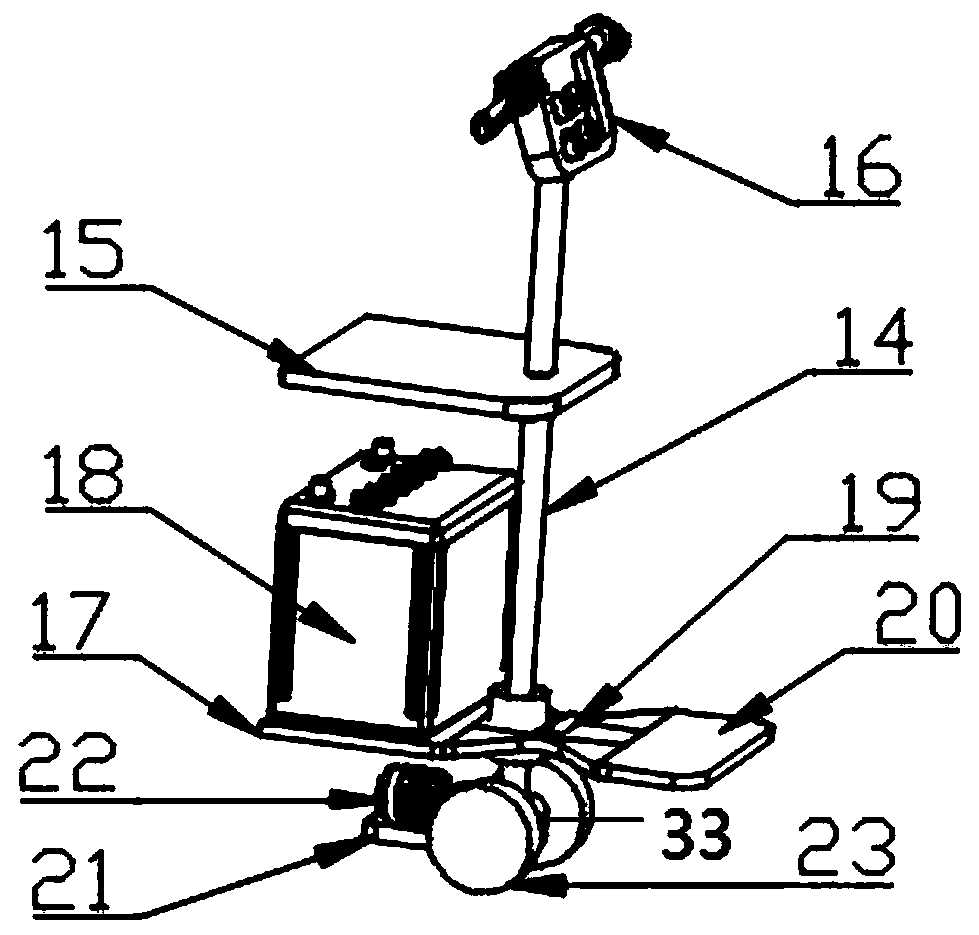

[0129] In this embodiment, the push-up cart is provided with a folding seat 40, a main folding area 36, a substrate installation strip 37, a substrate 38, and a substrate chute 39;

[0130] There are two substrate mounting strips 37, which are fixed on both sides of the bottom of the traveling device 30 in parallel; the substrate chute 39 is arranged inside the substrate mounting strip 37; the substrate 38 is installed in the substrate chute 39, and can slide back and forth along the substrate chute 39;

[0131] The main folding area 36 is arranged on the surface of the base plate 38; the folding seat 40 includes a seat plate 4011, a back plate 4012, a U-shaped support rod placement groove 4015, a seat plate support rod placement groove 4016, a U-shaped support rod 4017, and a U-shaped support rod support groove 4018, upright post 4019, support rod adjustment hole 4020, locking bolt 4021, backing plate chute 4022, backing plate adjustment hole 4023, post fixing hinge 4024, se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com