Novel anti-collision bucket and manufacturing method thereof

A production method and anti-collision technology, which are applied to roads, road signs, traffic signals, etc., can solve the problems of large municipal investment, consuming a lot of manpower and material resources, black pollution, etc., so as to avoid waste of resources, save manpower and material resources, and have a long service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in combination with specific embodiments and accompanying drawings.

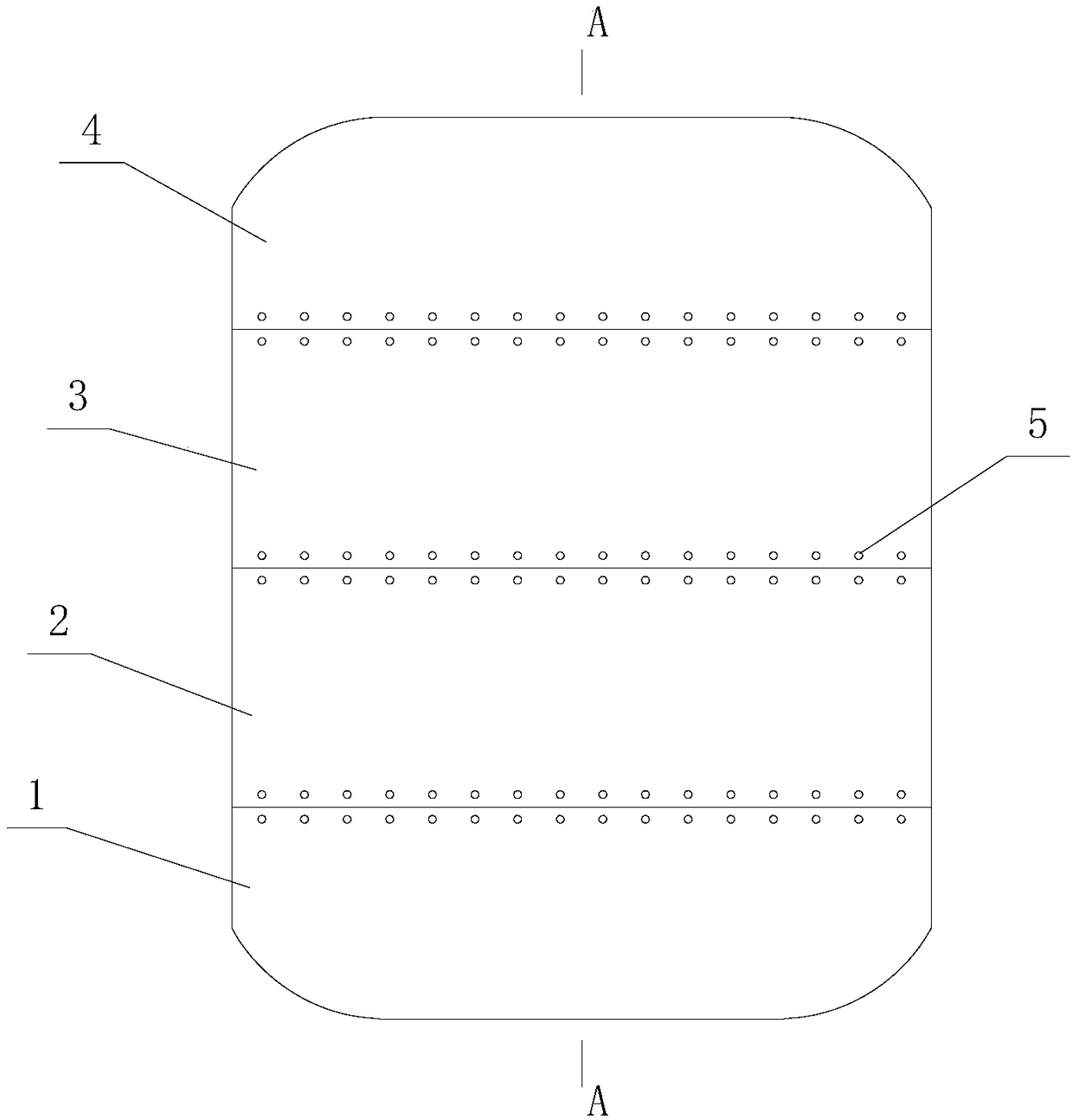

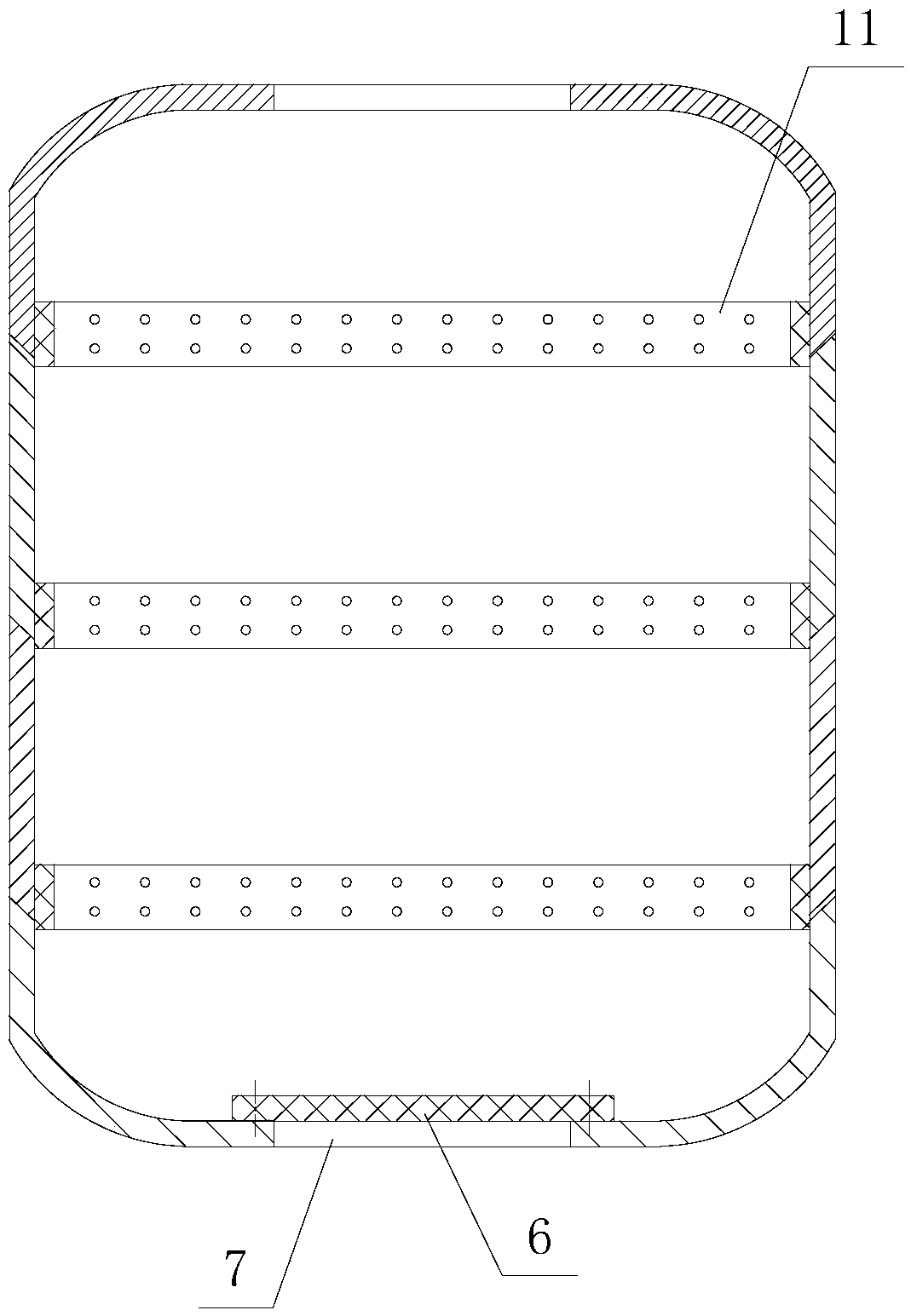

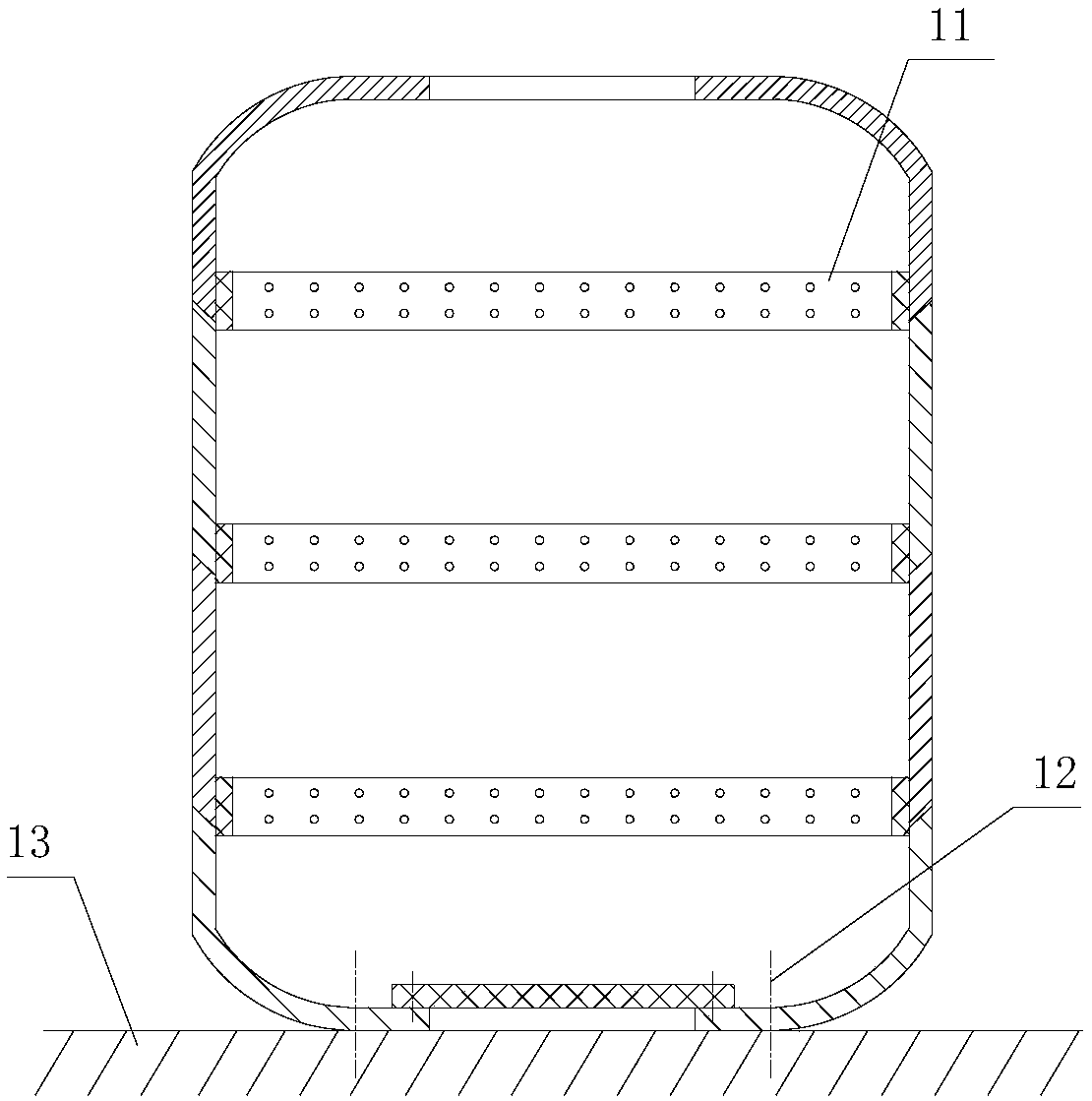

[0038] Such as Figure 1 to Figure 7 As shown, a new type of anti-collision bucket includes a bucket body, and the bucket body includes a base 1 made of waste tires, a first connecting body 2, a second connecting body 3 and a top 4, the base 1, the first The connecting body 2, the second connecting body 3 and the top 4 overlap successively from bottom to top and are connected by connecting nails 5 to form a barrel body with an internal cavity. With the cover plate 6 made.

[0039] Connect the seam 7 of cover plate 6 sealing tires as staving bottom surface by screw, then can fill soil planting plant in staving, not only increased anti-collision barrel integral weight, improves anti-collision effect, and has the effect of beautifying the environment. If there is no need to fill the soil to plant plants in the barrel body, then the top of the barrel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com