Rectangular pore-forming bit

A drill bit and assembly technology, which is applied in the direction of drill bits, drilling equipment, earthwork drilling, etc., can solve the problems that the drilling is not easy to be close to adjacent buildings, the drilling slope is large, and the construction is restricted, so as to improve the drilling quality and position accuracy, reduce the drilling inclination, and improve the rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

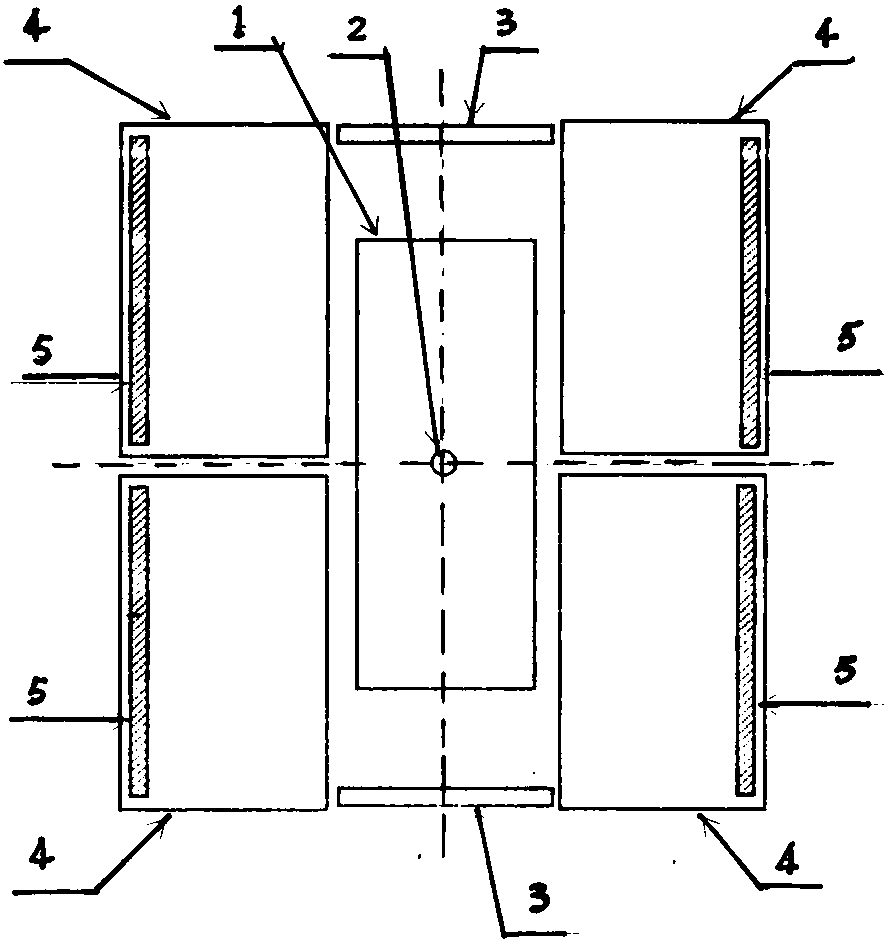

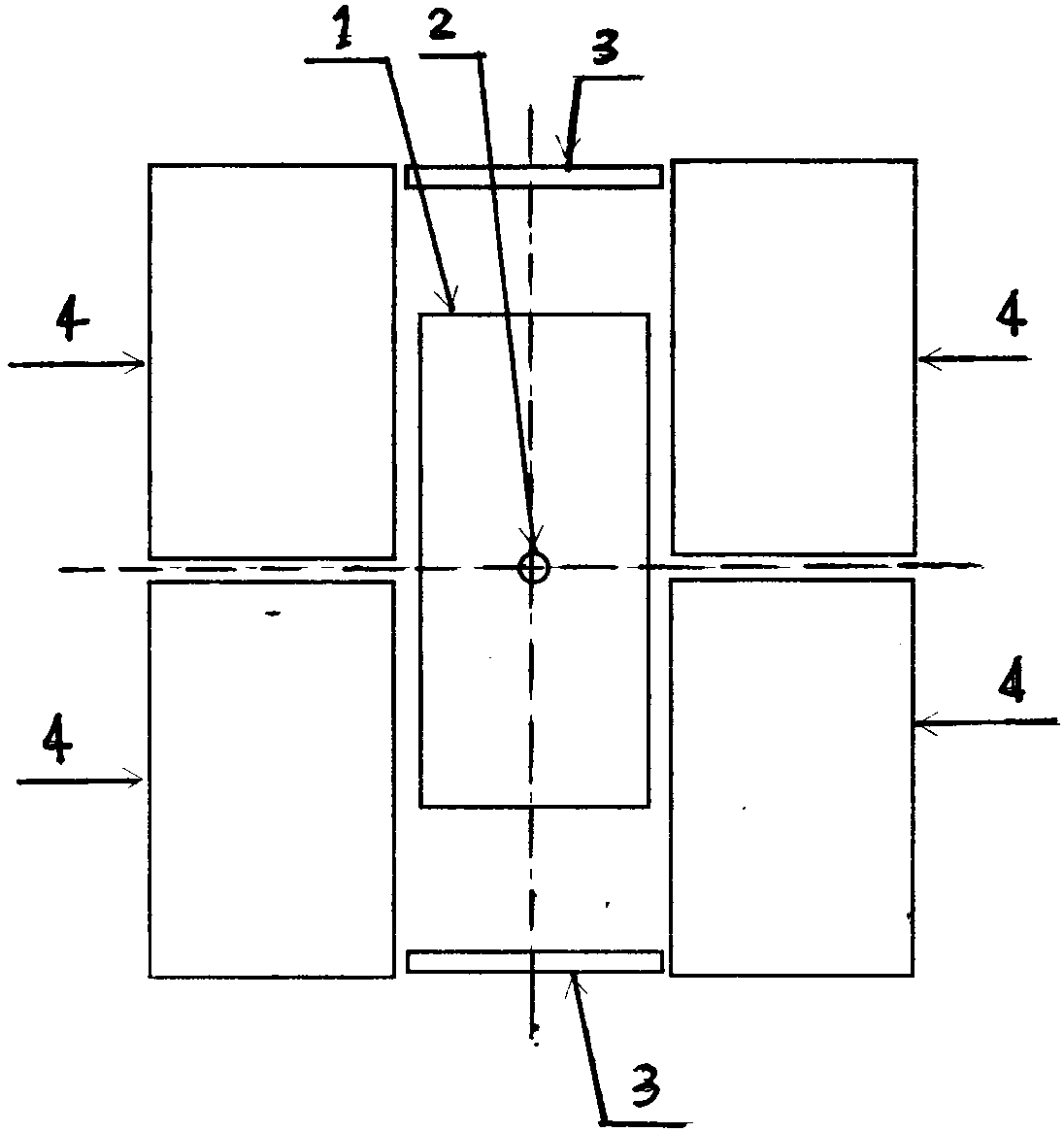

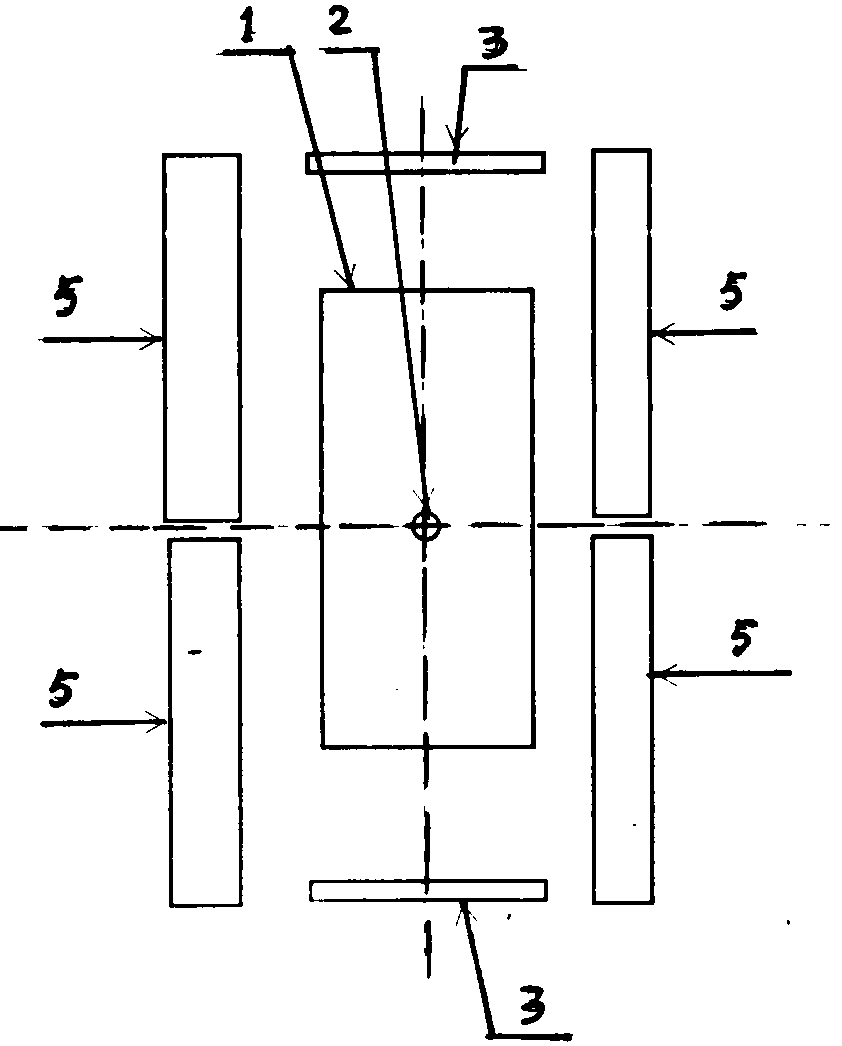

[0048] Embodiment 1, the present invention comprises a transmission assembly 1, two disc slide plates 3, four horizontal drill bits 4, four wire brushes 5, a vertical drill bit 6, the following of the transmission assembly 1 is connected to the transmission shaft 2 The vertical drill bit 6 is connected; the opposite sides of the transmission assembly 1 are respectively connected with the two disc slides 3 via the rotating shaft; the other two sides of the transmission assembly 1 are respectively connected with four horizontal drill bits 4 and four wire brushes 5. , there are three connection methods: 1. When there are structures underground on both sides, the working shaft 13 of the transmission assembly 1 is connected with four horizontal drill bits 4 and steel wire brushes 5 respectively, and the steel wire brushes 5 are arranged in the hollow of the horizontal drill bits 4; Two, when drilling independent holes or becoming continuous wall grooves, the working shaft 13 of the ...

Embodiment 2

[0049] Embodiment 2, the transmission assembly 1 includes a transmission shaft 2, a box body 7, a vertical bevel gear 8, a bevel gear one 9, a gear one 10, a gear two 11, two gears three 12, and two working shafts 13 , two bevel gears 14, hydraulic cylinder 15, two shift forks 16, four shift fork wheels 17; a vertical bevel gear 8 is fixed in the middle of the transmission shaft 2, and the lower end of the transmission shaft 2 is connected with a vertical drill bit 6. The transmission shaft 2 is worn on the box body 7 through bearings and seals; the vertical bevel gear 8 is fixed on the transmission shaft 2, and the vertical bevel gear 8 is connected with bevel gear one 9 and two bevel gear two 14 meshing; bevel gear one 9 meshes with vertical bevel gear 8, bevel gear one 9 is coaxial with gear one 10, and bevel gear one 9 is fixed in the box body 7 via shaft and bearing; Shaped gear one 9 is coaxial, gear one 10 meshes with gear two 11 and one gear three 12, and gear one 10 i...

Embodiment 3

[0050] Embodiment 3. The disc slide 3 is made of a circular steel plate, and the disc slide 3 is connected to the transmission assembly 1 via a rotating shaft.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com