High-pressure difference sleeve adjusting valve

A technology of sleeve regulating valve and high pressure difference, which is applied in the direction of lifting valve, valve details, valve device, etc., can solve the problems of loose closing of regulating valve, erosion, blowing damage of sealing surface, etc., and achieve the effect of avoiding blowing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

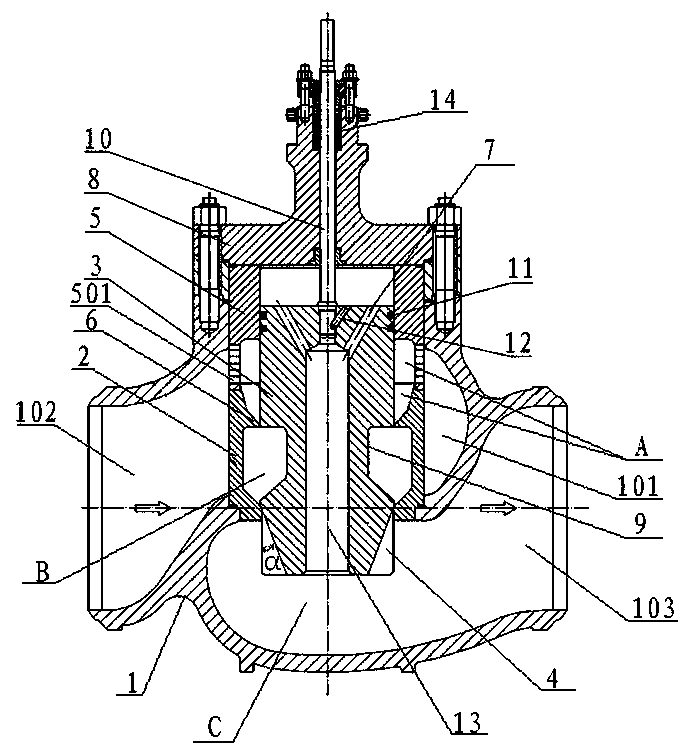

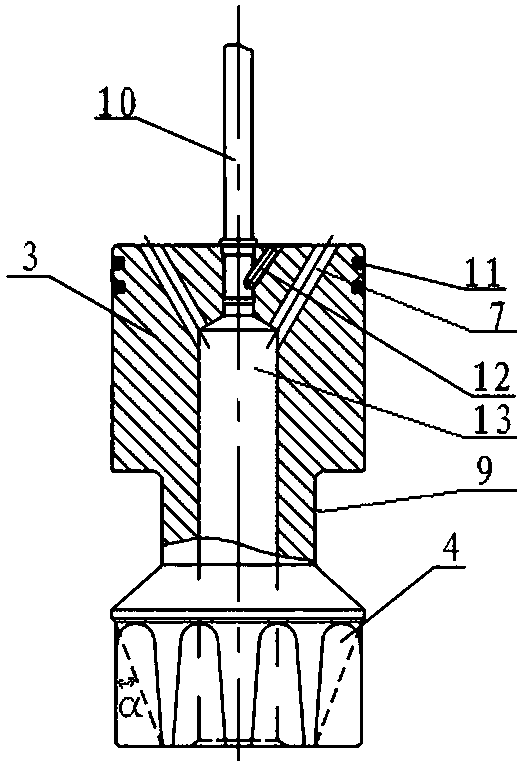

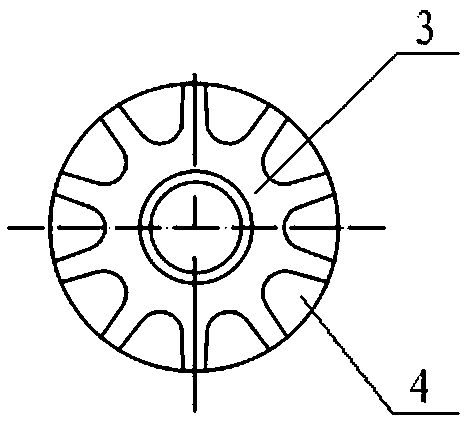

[0024] see Figure 1 to Figure 3 As shown: the present invention is a high-pressure differential sleeve regulating valve, including a valve body 1, a valve cover 8, and a valve trim arranged in the valve body 1 and the valve cover 8, and the valve trim further includes a valve cage 5 , a valve seat 2, a valve stem 10, and a valve core 3, the valve core 3 is fixedly connected to the lower end of the valve stem 10. In this embodiment, the top of the valve cavity 101 of the valve body 1 is sealed by the valve cover 8, and the valve cover 8 is provided with an axial through hole 13 of the valve stem 10, and one end of the valve stem 10 passes through the The axial through hole 13 of the bonnet 8 extends into the valve chamber 101 in the valve body 1, and is screwed with the internal thread at the top of the axial through hole 13 opened in the center of the valve core 3, and the locking screw 12 Fixed and locked; the valve stem 10 is axially arranged in the valve chamber 101 throu...

Embodiment 2

[0032] see Figure 4 , Figure 5 The other structure of this embodiment 2 is the same as that of embodiment 1, the difference is that the cross-sectional shape of the longitudinal flow regulating groove 4 of the valve core 3 is rectangular, and the depth of the longitudinal flow regulating groove 4 is monotonously deepened from top to bottom, and vertically The width of the flow regulating groove remains constant from top to bottom. It is easy to process.

Embodiment 3

[0034] Other structures of the third embodiment are the same as those of the first embodiment, except that: the notch of the adjusting groove is provided with an everted arc-shaped chamfer. When the spool opens and closes, it increases the area of the flow passage, reduces the erosion and erosion of high-speed fluid, and realizes the smooth transition of the spool opening and closing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com