Steel belt embedded type ultra-high molecular weight polyethylene compound pipe

A polyethylene composite pipe, ultra-high molecular weight technology, applied in the direction of pipes/pipe joints/fittings, pipes, rigid pipes, etc., to achieve the effect of reasonable structure design, smooth inner wall and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

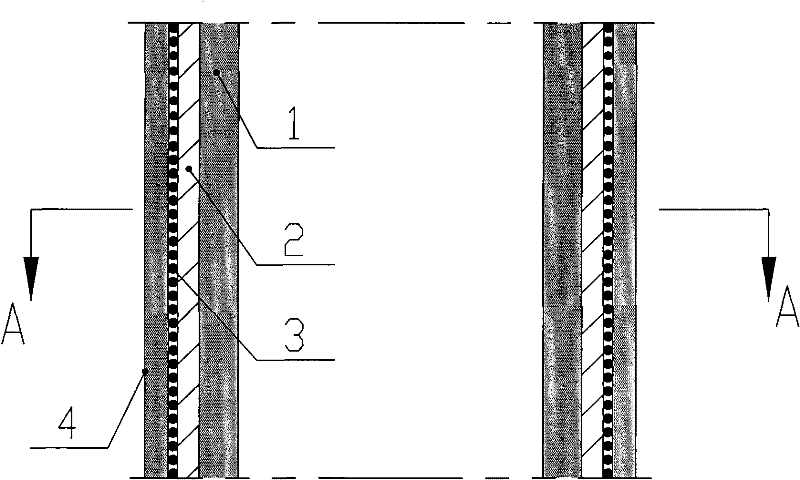

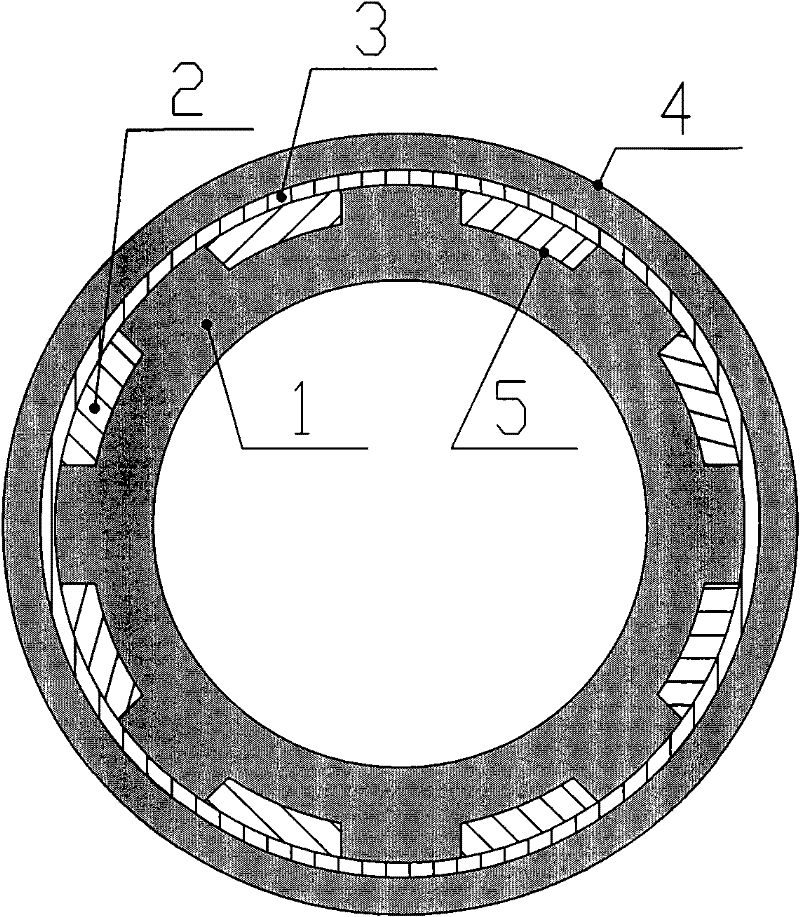

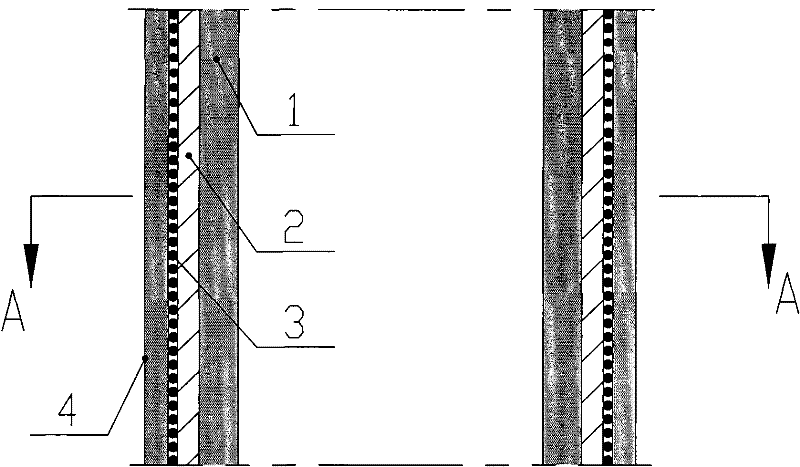

[0021] The invention as figure 1 As shown, a steel belt embedded ultra-high molecular weight polyethylene composite pipe is provided with a base tube, and grooves matching the thickness and width of the steel belt are uniformly arranged on the outer wall of the base tube, and the grooves run through the base tube. The overall length is parallel to the axis of the base tube, and the steel strip is embedded in the groove. The steel wire is perpendicular to the axis of the base tube in a helical winding structure wrapped with a steel strip. Polyethylene tubing, forming the outer wall.

[0022] The outer wall of the steel wire is wrapped with strip-shaped helically wound radiation cross-linked polyethylene stretch tape to form the outer wall.

[0023] Wrap hot-melt PE plastic on the outer wall of the steel wire to form the outer wall.

[0024] The thickness of the steel strip is 0.5-3 mm, and the distance between the grooves is 10-20 mm. The steel strip is wrapped and coated wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com