A Five-Dimensional Radar Graphical Monitoring Method for Boiler Operation Safe State

A technology for safe state and boiler operation, which is applied to steam boilers, steam boiler accessories, and components of steam boilers. Service production is convenient and the effect of improving boiler monitoring efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

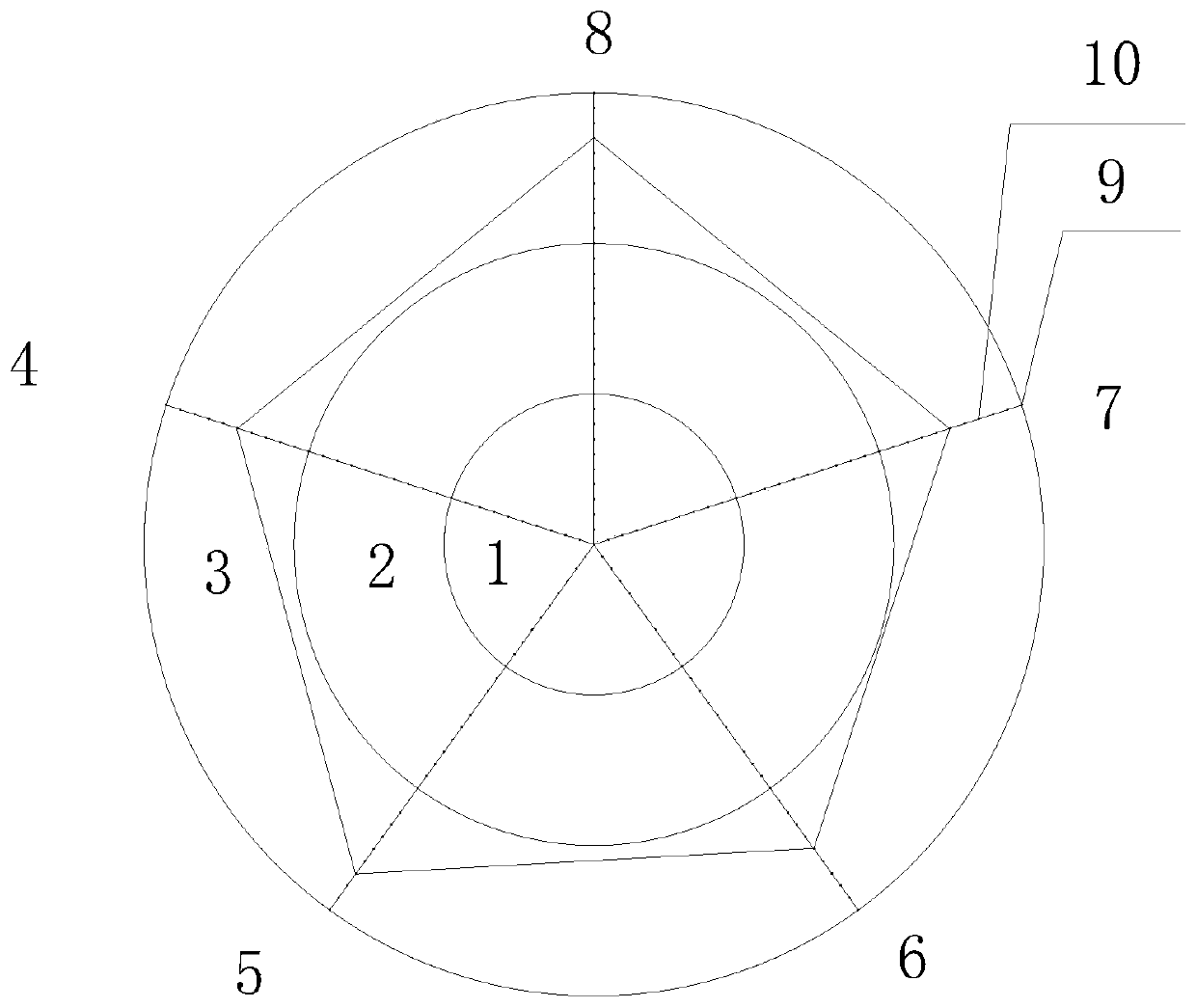

[0031] A five-dimensional radar graphic monitoring method for a boiler operating safety state according to the present invention will be described in detail below in conjunction with the embodiments and accompanying drawings.

[0032] A five-dimensional radar graphic monitoring method for the safety state of boiler operation of the present invention will affect the key data of the safe operation of the boiler, mainly including the maximum temperature of the water wall, the maximum temperature of the superheater, the system pressure, the wall thickness of the furnace tube for daily inspection and maintenance, and the temperature of the furnace tube. Collect and analyze the life value, etc., use these key data to determine the safe state of the boiler through corresponding algorithm strategies, and arrange them reasonably in the five-dimensional radar map to show the real-time safety level of all boiler operations for boiler managers, which is intuitively reflected Security issue...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com