Method for Determination of Plasticizer Content in Water Samples by Hollow Fiber Membrane Microextraction Combined with Flash Gas Chromatography

A technology of fiber membrane and flash gas, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of low extraction efficiency, achieve the effect of less extraction steps, good sample purification ability, and avoid cross-contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

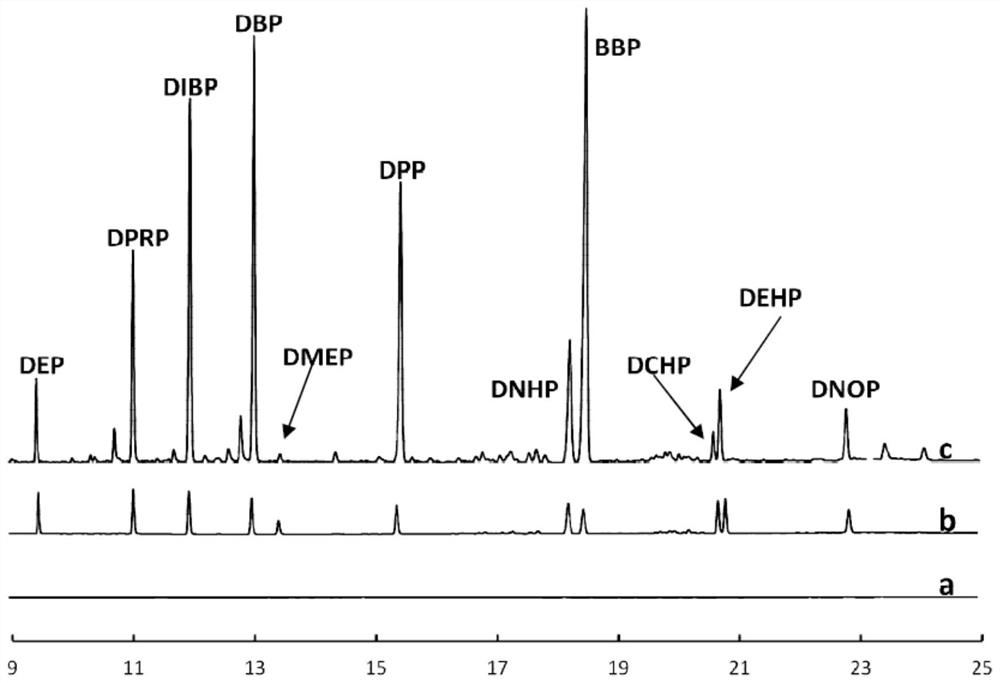

[0044] The selection of embodiment 1 extraction time

[0045] The longer the extraction time, the more beneficial the target substance to enter the membrane, and increasing the extraction time after reaching equilibrium has little effect on the increase of extraction efficiency. Prolonging the extraction time after equilibration will lead to membrane instability, resulting in a decrease in extraction efficiency. The extraction efficiencies of 10, 20, 30, 40, and 50 min of extraction were investigated respectively. Other experimental conditions were: extraction temperature was 40°C, and stirring rate was 300 rpm. The results show that with the increase of time, the extraction efficiency of the target substance has been significantly improved. When the phthalates reach the extraction equilibrium at about 30 minutes, the extraction efficiency will decrease instead as the time continues to increase, and continuing to prolong the extraction time after the equilibrium will lead to ...

Embodiment 2

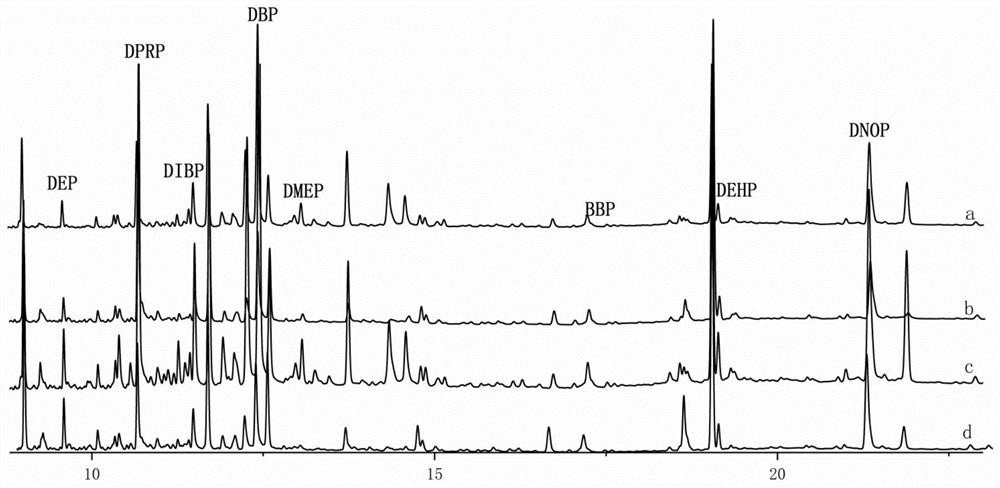

[0046] The selection of embodiment 2 extraction temperature

[0047] Raising the temperature can promote the entry of target substances from the water sample to the fiber membrane. However, thermodynamically, adsorption equilibrium is an exothermic process, and the partition coefficient will decrease with increasing temperature, resulting in a decrease in extraction efficiency. The extraction efficiency at the extraction temperature of 30, 40, 50, 60, and 70°C was investigated respectively. Other experimental conditions were: the extraction time was 30min, and the stirring rate was 300rpm. The extraction efficiency is the highest at 50°C, so the extraction temperature of 50°C is selected.

Embodiment 3

[0048] The selection of embodiment 3 stirring speed

[0049] Accelerating the stirring speed can improve the mass transfer process, accelerate the speed of the target substance entering the membrane, and improve the extraction efficiency, but too fast stirring will destroy the structure of the membrane and reduce the extraction efficiency. The extraction efficiency was investigated when the stirring speed was 100, 200, 300, 400, and 500rpm. Other experimental conditions were: the temperature was 50°C, and the extraction time was 30min. The results showed that the extraction efficiency was the highest at 300rpm, so the stirring rate was selected at 300rpm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com