Fracture simulation method for fractured tight sandstone oil-gas reservoir

A technology of tight sandstone and simulation method, which is applied in the field of fractured oil and gas reservoirs in oil exploitation, and can solve the problems of single simulation and difficulty in controlling the mixing ratio of sand with different meshes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

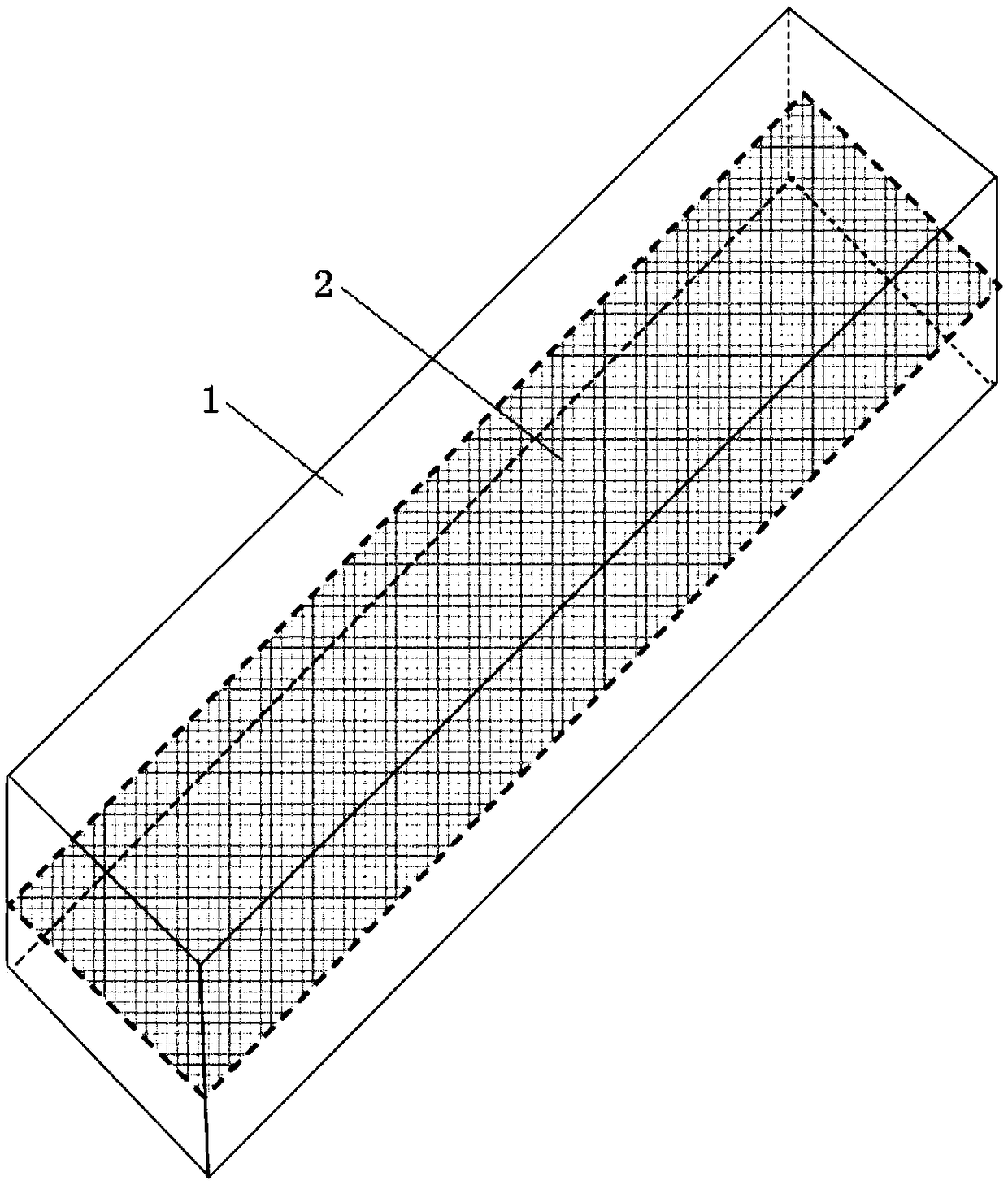

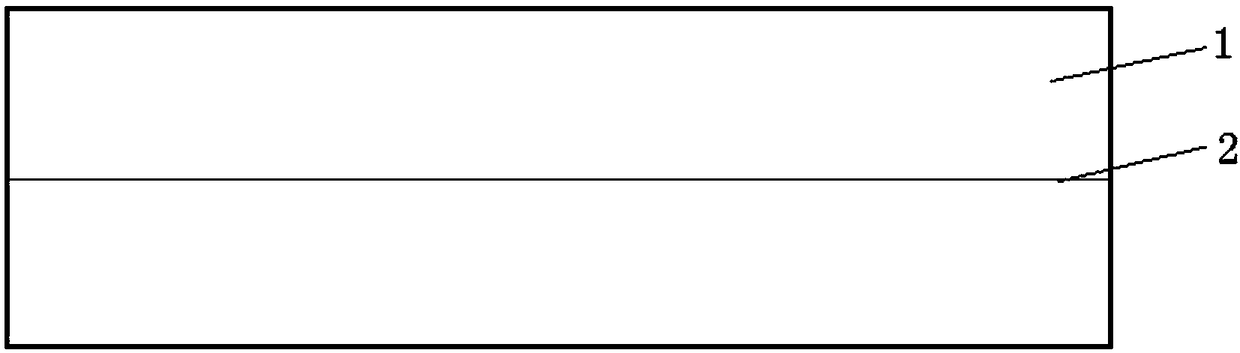

Image

Examples

example 1

[0084] Example 1: Under the condition of 10MPa confining pressure, the crack opening and permeability of 1-layer gauze

[0085] In this embodiment, the physical model used in the experiment is a 1-layer gauze mesh fractured core model. Under the condition of 10MPa confining pressure, the experimental results of the 1-layer gauze mesh crack opening and permeability are shown in Table 1 and image 3 , Figure 4 shown. Under the condition of 10MPa confining pressure and 60℃, the crack opening of the first layer of gauze is 0.08mm, and the permeability is 4.29mD. Among them, the pump speed was set to 0.2ml / min and 0.4ml / min respectively, and the permeability of the cracks in the first layer of gauze was measured to be 4.2mD and 4.4mD respectively, with an average of 4.29mD.

[0086] Table 1 Experimental results of cracks in 1-layer gauze

[0087]

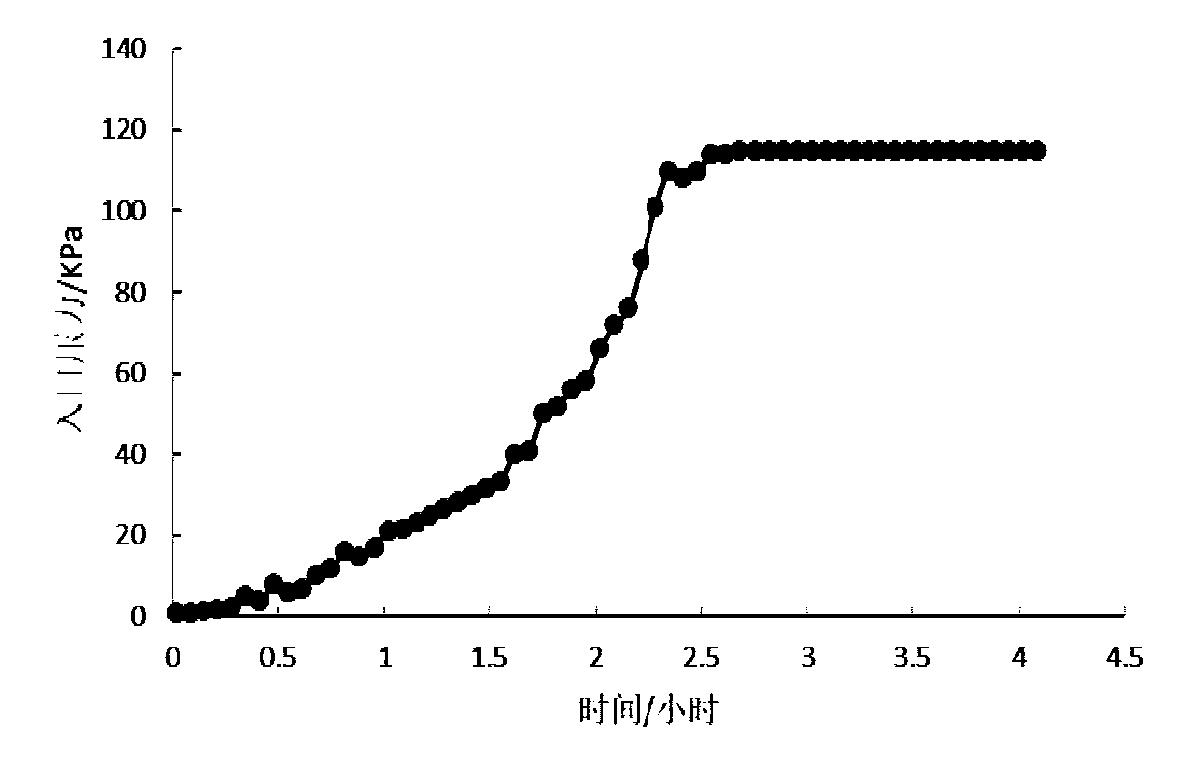

[0088] image 3 and Figure 4 Shown are the inlet pressure curves at different flow rates: at a flow rate of 0.2ml / min, the in...

example 2

[0089] Example 2: Under the condition of 10MPa confining pressure, the crack opening and permeability of 3 layers of gauze

[0090] In this example, the physical model used in the experiment is a 3-layer gauze fractured core model. Under the condition of 10MPa confining pressure, the experimental results of the 3-layer gauze crack opening and permeability are shown in Table 2 and Figure 5 , Image 6 shown. Under the conditions of 10MPa confining pressure and 60℃, the thickness of the crack in the three-layer gauze is 0.24mm, and the permeability is 87.865mD. Among them, the pump speed was set to 0.2ml / min and 0.4ml / min respectively, and the permeability of the cracks in the three layers of gauze was measured to be 75.97mD and 99.76mD respectively, with an average of 87.865mD.

[0091] Table 2 Experimental results of cracks in 3-layer gauze

[0092]

[0093] Figure 5 and Image 6 The inlet pressure curves at different flow rates are shown respectively: under the flow ...

example 3

[0094] Example 3: Under the condition of 10MPa confining pressure, the crack opening and permeability of 5 layers of gauze

[0095] In this example, the physical model used in the experiment is a 5-layer gauze fractured core model. Under the condition of 10MPa confining pressure, the experimental results of the 5-layer gauze crack opening and permeability are shown in Table 3 and Figure 7 , Figure 8 shown. Under the conditions of 10MPa confining pressure and 60℃, the thickness of the crack in the 5-layer gauze is 0.42mm, and the permeability is 295.42mD. Among them, the pump speed was set to 0.2ml / min and 0.4ml / min respectively, and the permeability of the cracks in the five layers of gauze was measured to be 308.64mD and 282.19mD respectively, with an average of 295.42mD.

[0096] Table 3 Experimental results of cracks in 5-layer gauze

[0097]

[0098]

[0099] Figure 7 and Figure 8 The inlet pressure curves at different flow rates are shown respectively: at a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Permeability | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com