Machine head mesh leveling device and method for computerized flat knitting machine

A computerized flat knitting machine and machine head technology, applied in textiles and papermaking, weft knitting, knitting, etc., can solve problems such as inconsistent system parameters and work difficulties, and achieve the effects of convenient operation, avoiding technical problems, and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

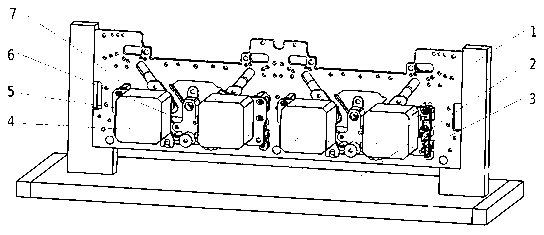

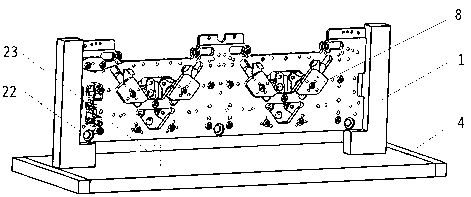

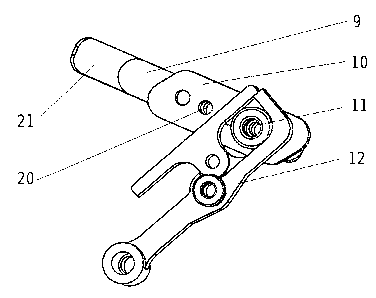

[0022] like figure 1 , 2 , 3, 4, and 5, the head stitch leveling device of the computerized flat knitting machine includes a fixed fixture 1, a workbench 2, a triangular bottom plate 3 and a stitch movement module, and the stitch movement module includes a stitch motor 4, a stitch motor plate 5, a Zhongshan Bracket 6, casting 7, stitch 8, slider 9, slider cover 10, stitch bearing 11, clip 12, swing rod bearing 13, cam 14, first screw 15, second screw 16, first positioning pin 17 , the third screw 18, the Hall element 19, the second positioning pin 20, the chute 21, the bolt 22, and the block 23; The fixture 1 is fixed, the stitch motor 4 and the stitch motor plate 5 are fixed, the stitch motor plate 5 is positioned by the first positioning pin 17, and fixed on the casting 7 and the Zhongshan bracket by the first screw 15, the second screw 16, and the third screw 18 6, the casting 7 is fixed to the triangular bottom plate 3, the Zhongshan bracket 6 is fixed to the triangular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com