Separating flotation device and method for micro plastics in environment soil and sediment samples

A flotation device and sediment technology are applied in the research field of pretreatment of environmental pollutants, which can solve the problems of long time and complicated operation, and achieve the effects of simple operation, low cost and wide application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

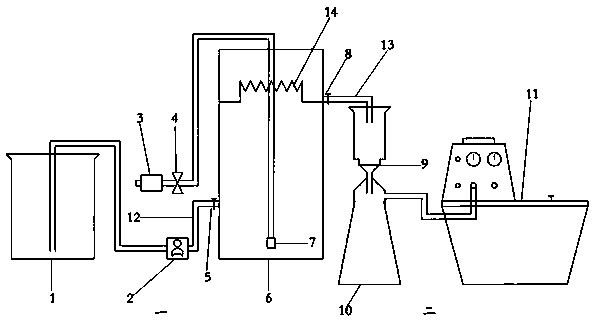

[0024] A separation and flotation device for microplastics in environmental soil and sediment samples, including a separation reactor part (1) and a filter part (2), wherein

[0025]The separation reactor part (1) includes: columnar reaction body 6, air pump 3, gas flow meter 4, aeration head 7, water outlet valve 8, water outlet pipe 13, water inlet valve 5, water inlet pipe 12, peristaltic pump 2, storage The liquid cup 1; the water outlet valve 8 and the water inlet valve 5 are located on the side wall of the columnar reaction body 6, the aeration head 7 is placed at the bottom of the columnar reaction body 6, and the gas flow meter 4 is located between the air pump 3 and the aeration head 7 On the connected pipeline, one end of the peristaltic pump 2 is connected to the water inlet valve (5) through the water inlet pipe 12, and the other end is inserted below the liquid level of the liquid storage cup to pump the flotation liquid in the liquid storage cup into the columnar ...

Embodiment 2

[0028] The invention utilizes aeration and overflow methods to separate and float microplastic particles in soil or sediment samples and designs a corresponding separation and floatation device. The specific operation is as follows:

[0029] A separation and flotation device for microplastics in environmental soil and sediment samples, including a separation reactor part and a filter part, wherein the separation reactor part includes a columnar reaction body, an air pump, a gas flow meter, an aeration head, a water outlet valve, Outlet pipe, water inlet valve, water inlet pipe, peristaltic pump, liquid storage cup, filter part includes filter membrane, recovery bottle and vacuum filtration pump. Both the water outlet valve and the water inlet valve are located on the side wall of the columnar reaction body; the aeration head is placed at the bottom of the columnar reaction body; the gas flow meter is located on the pipeline connected between the air pump and the aeration head;...

Embodiment 3

[0034] A separation and flotation method for microplastics in environmental soil and sediment samples, using aeration and overflow methods to separate and float microplastic particles in soil or sediment samples. First, the water outlet valve is closed, pour the required flotation liquid into the columnar reaction body, turn on the air pump, adjust the gas flow meter, and feed a constant gas, and the gas is dispersed into small bubbles and released to the buoyant tank through the aerator head. In the liquid selection; then, slowly pour the sample from the top of the columnar reaction body, after all the samples are poured in, continue to aerate for a certain period of time, start the peristaltic pump, pump a part of the solution in the liquid storage cup into the columnar reaction body, and start Open the water outlet valve at the same time as the peristaltic pump, the upper flotation liquid carries the low-density substances through the overflow structure, flows out from the o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com