Copper-clad aluminum rod single pull ejecting machining device

A technology of copper-clad aluminum and rod reel, which is applied in the field of copper-clad aluminum production, and can solve problems such as skin damage of aluminum rods and difficulties in coiling and unwinding of aluminum rods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the purpose, technical solutions and beneficial effects of the present invention more clear, the following will further describe the implementation of the present invention in detail in conjunction with the accompanying drawings.

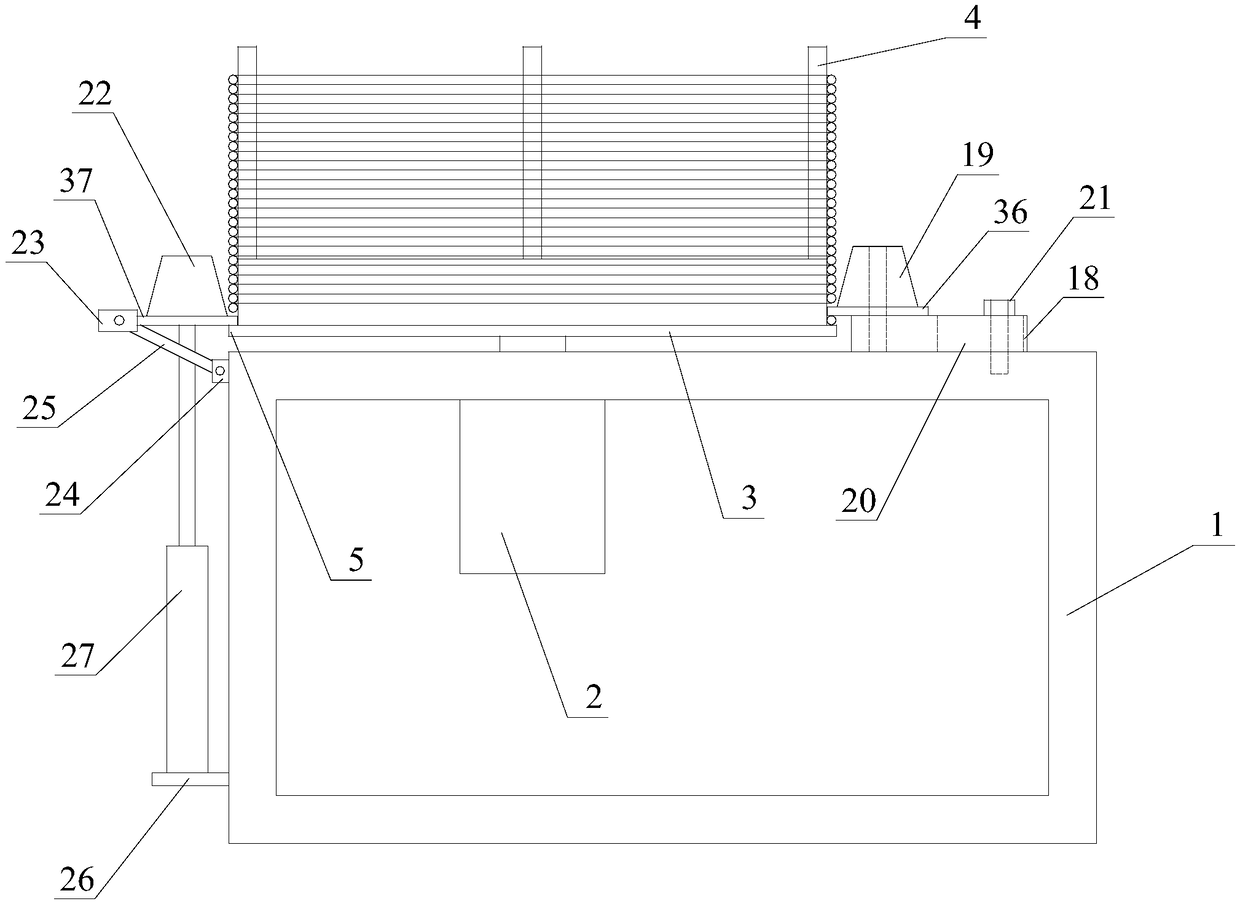

[0016] like figure 1 As shown, the present invention provides a copper-clad aluminum rod single-pull push-push processing device, including a support platform 1 and a motor 2, the rotating shaft of the motor 2 passes through the supporting platform 1 and the end of the rotating shaft is fixedly connected to a turntable 3. The top of the turntable 3 is fixedly connected with a plurality of vertical support rods 4 along the circumferential edge, and the lower end of the turntable 3 is provided with a placement boss 5 along the circumferential edge, and also includes a pulling device, a pushing device and a lubricating device .

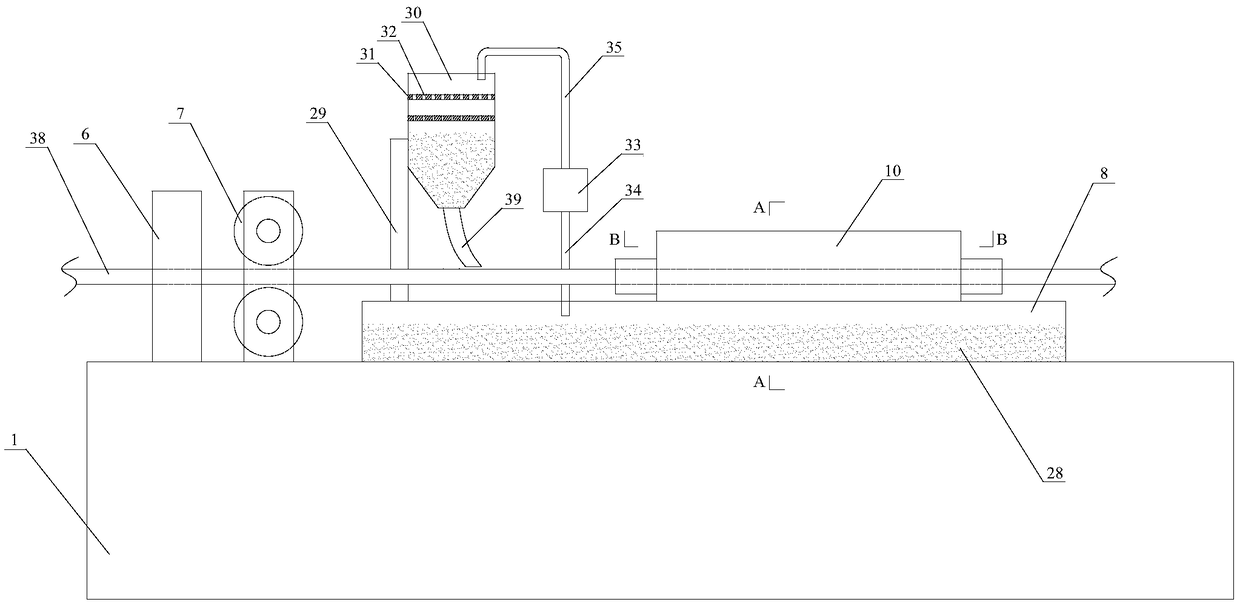

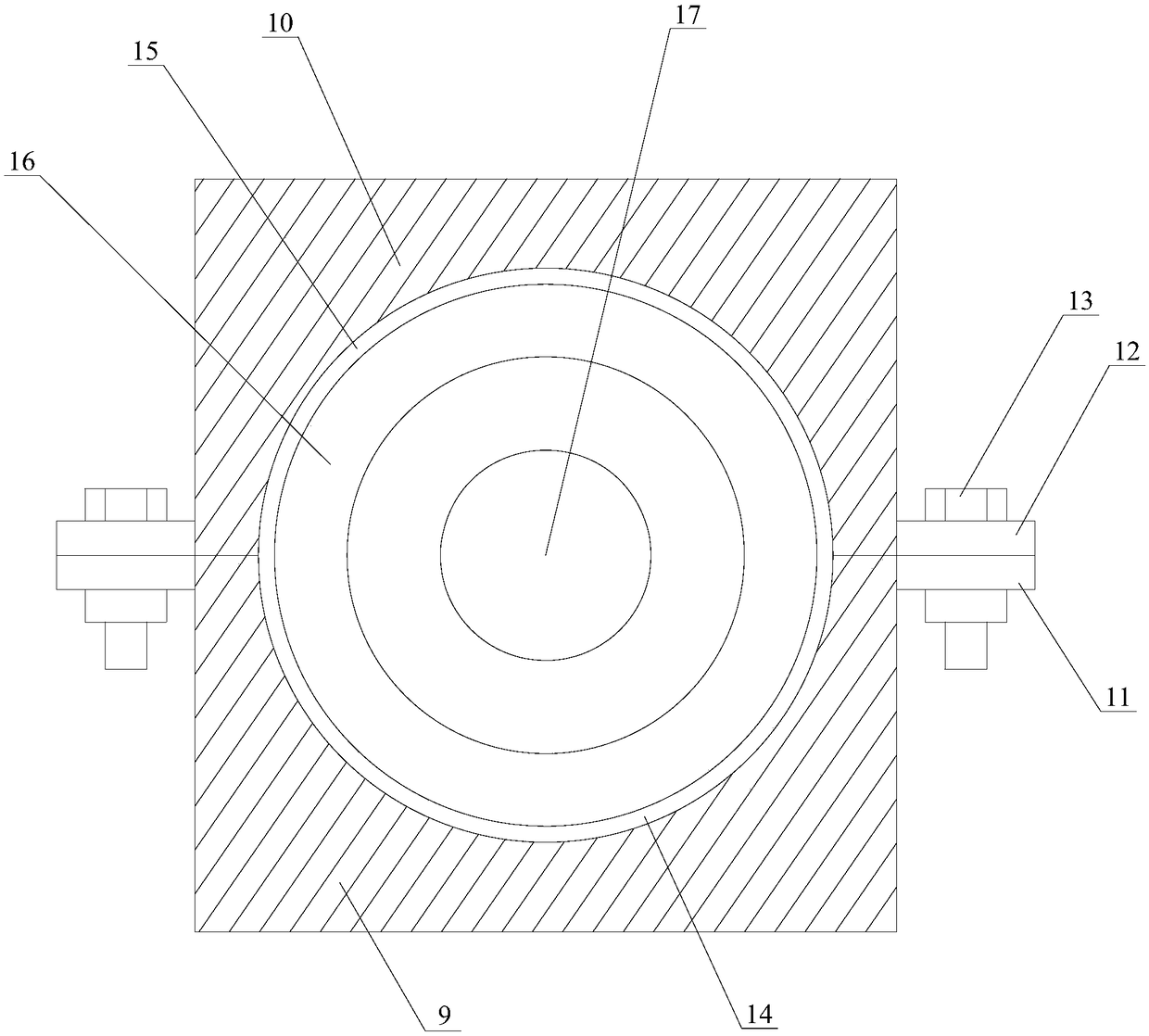

[0017] like figure 2 , image 3 As shown, the pulling device includes two vertical rollers 6, tw...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap