3D printer nozzle

A technology of 3D printers and nozzles, which is applied in the field of 3D printing, can solve the problems of poor heat dissipation at the heat dissipation end of the nozzle, unreasonable structure design of the nozzle, and abnormal filament discharge from the nozzle, etc. The effect of length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

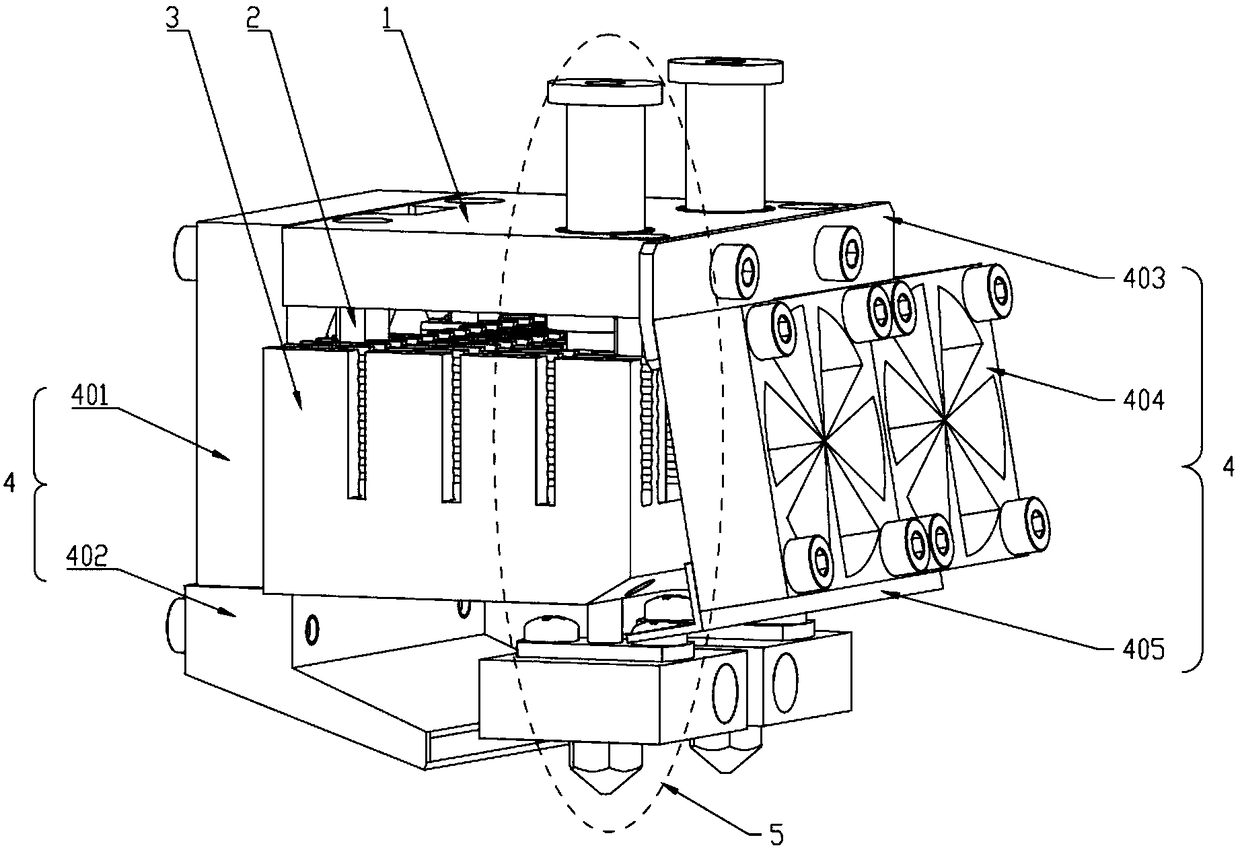

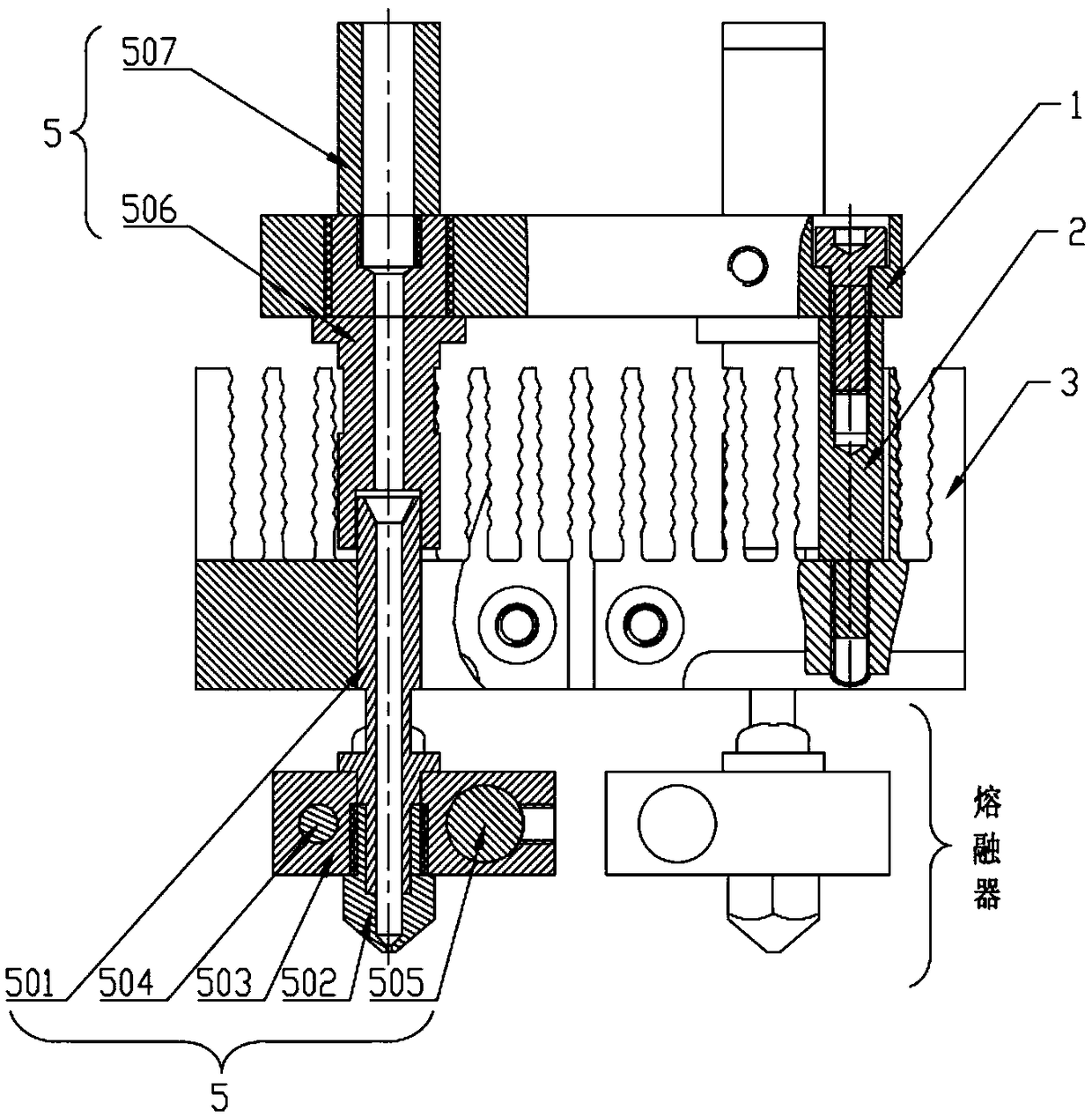

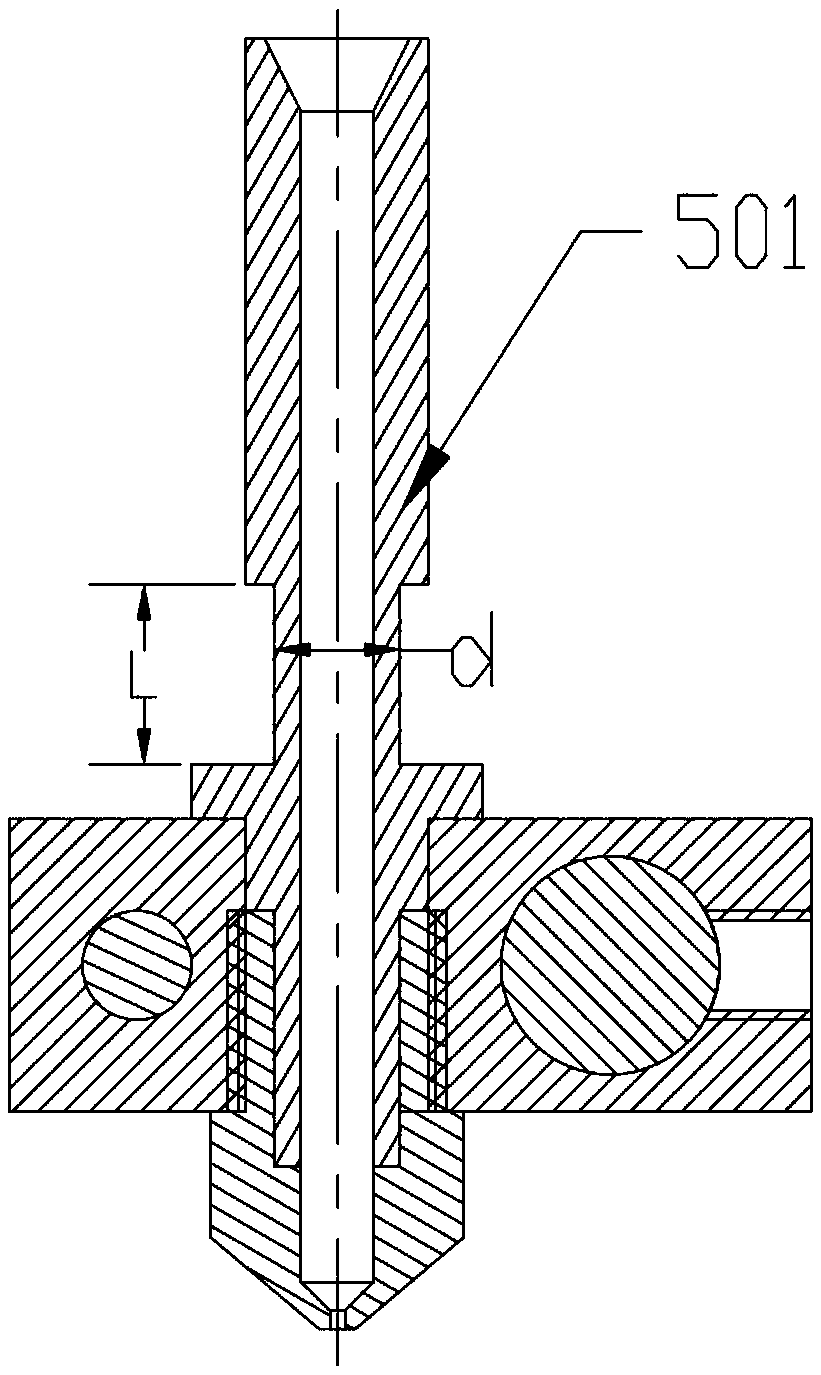

[0034] Such as Figure 1 to Figure 4 As shown, a 3D printer nozzle includes a substrate 1, a connecting column 2, a heat dissipation block 3, an air cooling system 4, and two fused filament assembly 5 installed symmetrically from left to right. The base plate 1 is the mounting plate of the entire printing head, and all components are directly or indirectly installed on it; the heat dissipation block 3 is fixed under the base plate 1 through a number of uniformly arranged connecting columns 2, and the molten wire assembly 5 is connected with the base plate 1 and the heat dissipation plate respectively. The block 3 is fixedly connected, the air cooling system 4 is installed on the front and rear ends of the substrate 1, and the air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com