Conveying device used for industrial robot to screen products

A technology of industrial robots and transmission devices, applied in conveyors, vibrating conveyors, transportation and packaging, etc., can solve problems affecting consumers, product occlusion, and product qualification screening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

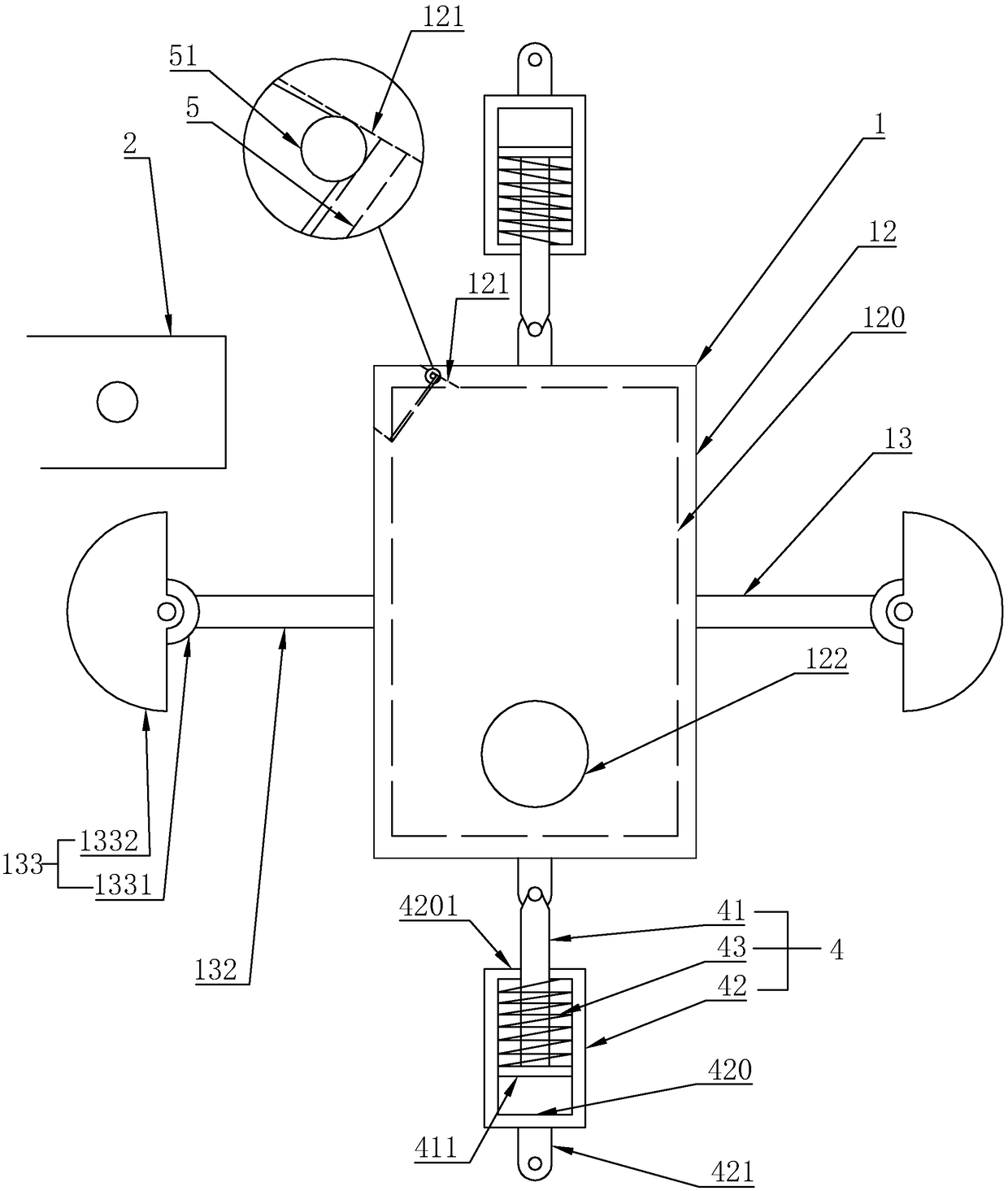

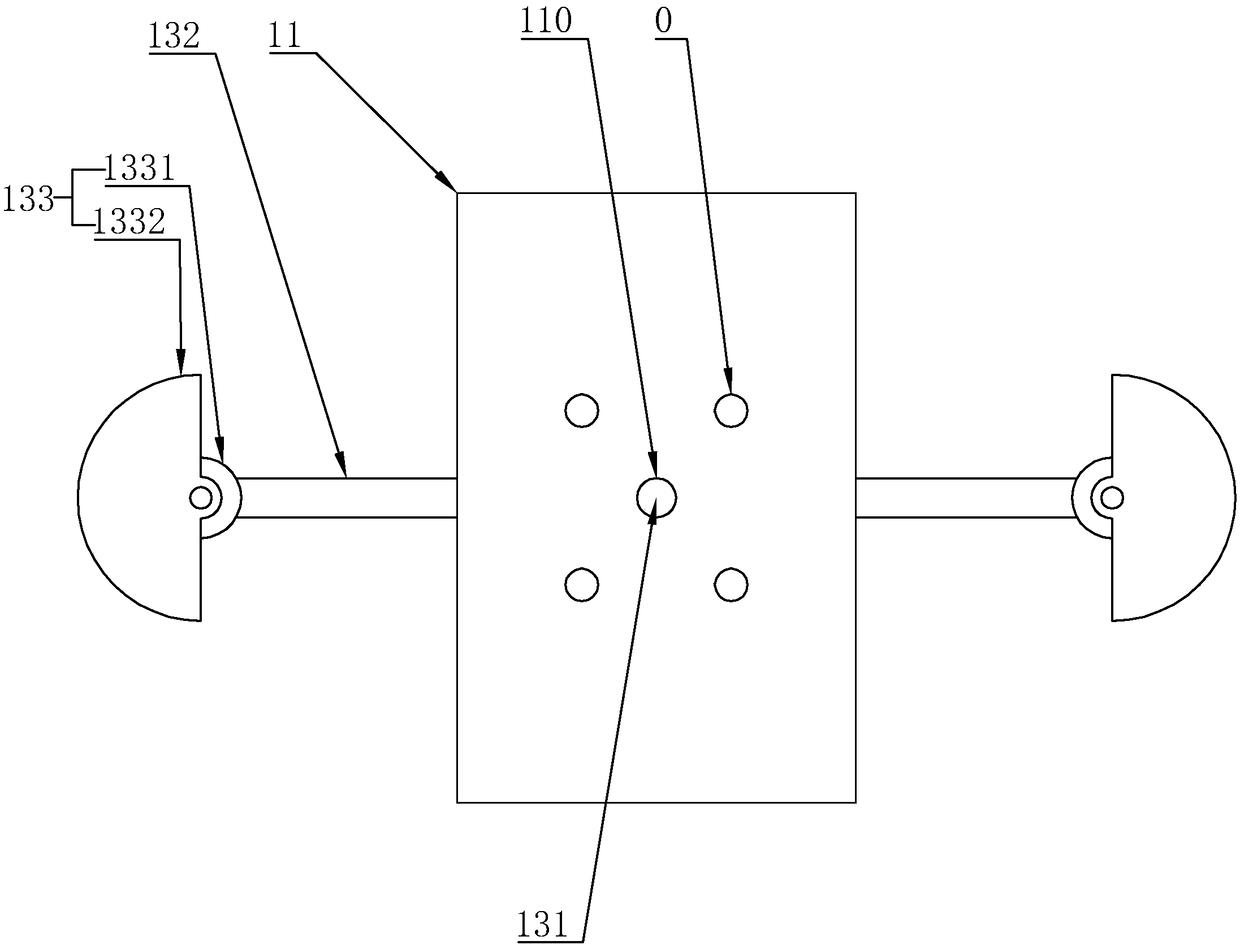

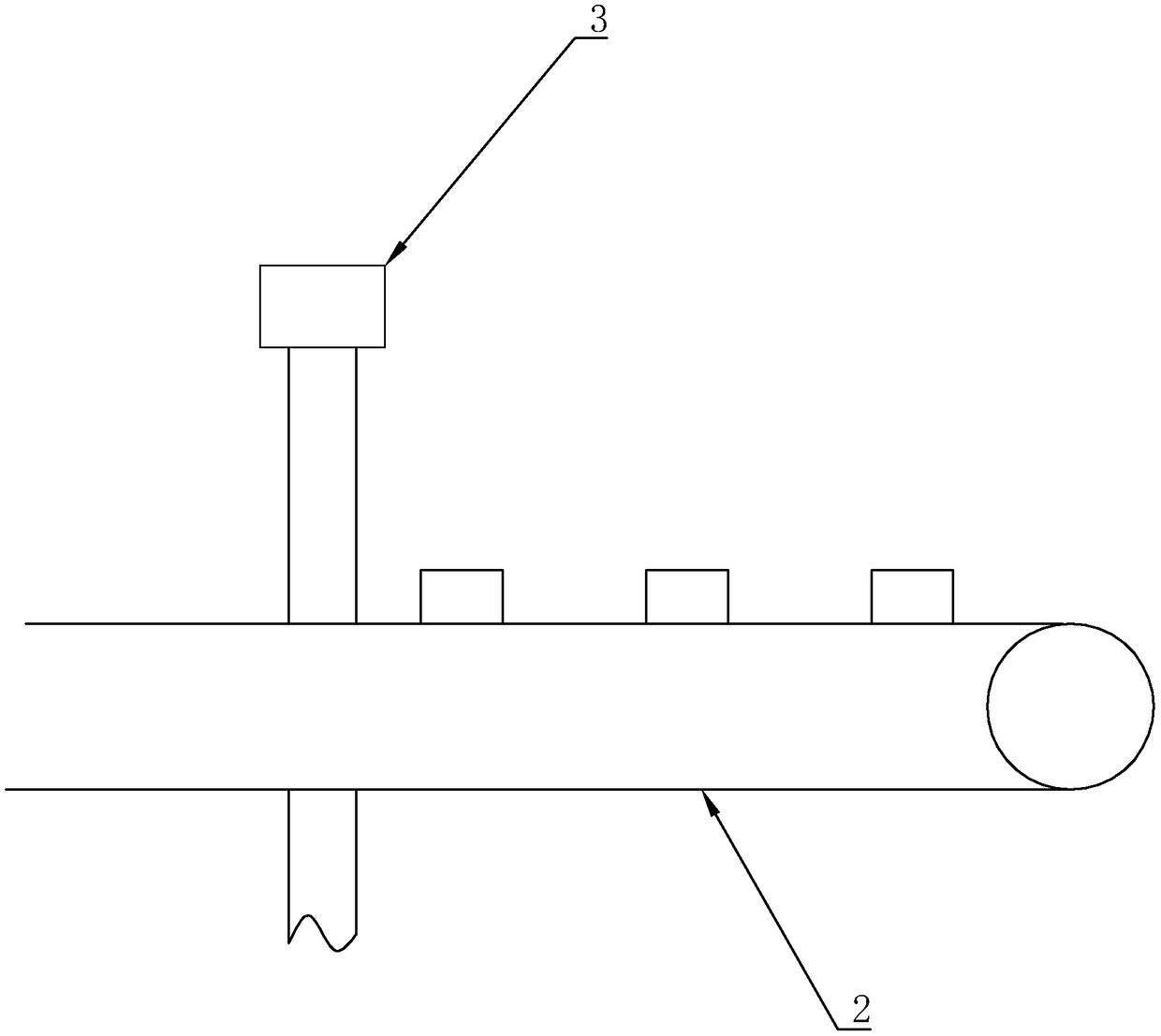

[0019] As an improved specific embodiment, there are two driving rods 132 and two driving assemblies 133 , and the driving rods 132 and driving assemblies 133 are arranged symmetrically along the connecting rod 131 .

[0020] Through the above technical solution, the drive assembly 133 and the drive rod 132 arranged on the opposite side move in reverse, which increases the amplitude of the vibrating plate 12, improves the vibration effect of the vibrating plate 12, and then increases the centrifugal force generated when the vibrating plate 12 vibrates, making the product from The sliding out process of the through hole 121 is more stable.

[0021] As an improved specific implementation, the drive assembly 133 includes a drive motor 1331 and a counterweight 1332, the drive motor 1331 is fixedly connected to the drive rod 132 parallel to the connecting rod 131, and the counterweight 1332 is fixedly connected On the rotating shaft of the driving motor 1331, when the driving motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com