Metal shielding net

A technology of metal shielding net and shielding cylinder, which is applied in the field of shielding net, can solve problems such as potential safety hazards, human injury, and easy leakage of microwaves, and achieve the effects of ensuring safety, avoiding injuries, and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

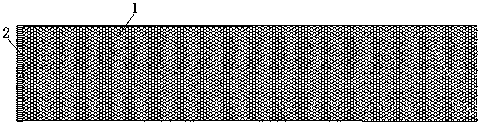

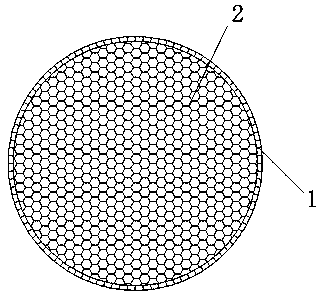

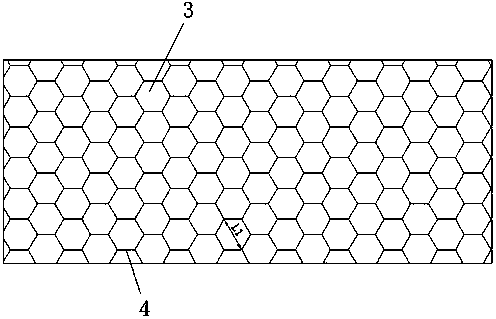

[0025] see Figure 1-5 , a metal shielding net, including a shielding tube 1 and a shielding cover 2; one end of the shielding tube 1 is open, and the other end of the shielding tube 1 is fixedly installed with a shielding cover 2; the shielding tube 1 and the shielding cover 2 are both made of different Made of magnetic 316L stainless steel; the shielding tube 1 and the shielding cover 2 are provided with a number of hexagonal meshes 3 evenly distributed; the length of the diagonal L1 of the hexagonal meshes 3 is 6mm-7mm; the meshes 3 The thickness of the web edge 4 is 0.5-1.5mm, preferably 1mm.

[0026] The shielding tube 1 is equipped with a lamp assembly for emitting ultraviolet rays to remove algae, sterilize and sterilize the fluid; the lamp assembly includes two lamp stands 5 and four lamp tubes 6; the two ends of the four lamp tubes 6 are respectively installed on two On the light frame 5, four mounting holes 7 are provided on the light frame 5 for passing through the...

Embodiment 2

[0029] On the basis of Embodiment 1, the shielding cylinder 1 has a cylindrical structure, the outer diameter of the shielding cylinder 1 is 100mm, and the thickness of the shielding cylinder 1 is 0.3mm.

Embodiment 3

[0031] On the basis of Embodiment 1, the shielding cover 2 has a circular structure, the diameter of the shielding cover 2 is 100 mm, and the thickness of the shielding cover 2 is 0.3 mm.

[0032] The working principle of the present invention is: the present invention rationally designs the material of the metal shielding net and the size of the mesh 3 according to the wavelengths and different orientations of microwaves and ultraviolet rays. And through the simulation experiment measurement, the spectrum outside the metal shielding net only contains ultraviolet wavelengths, which proves that the metal shielding net can shield microwaves.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com